Patents

Literature

84results about How to "Does not affect binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

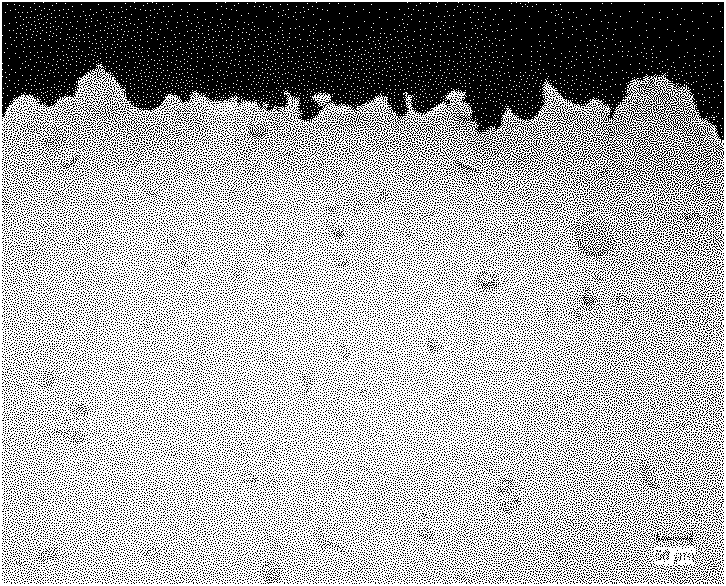

Treatment method for improving oxidation resistance of thermal barrier coating (TBC) bonding layer

InactiveCN102719782AImprove tissue morphology and surface compactnessSmooth surfaceMolten spray coatingSurface finishingVoltage

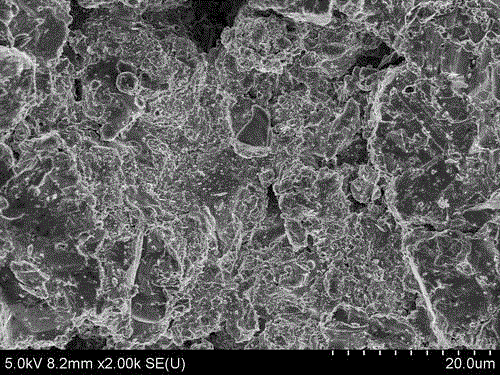

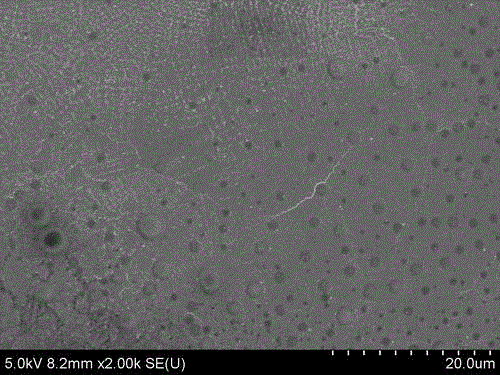

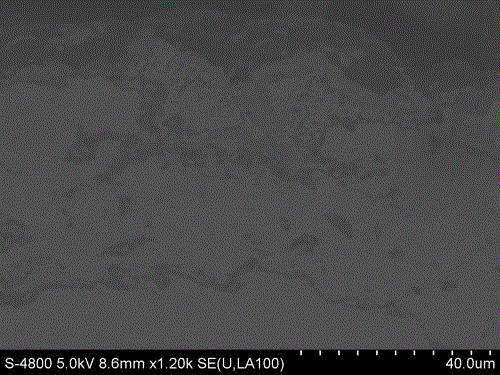

The invention relates to a treatment method for improving the oxidation resistance of a thermal barrier coating (TBC) bonding layer, and belongs to the technical field of surface treatment and modification of the TBC bonding layer. In the material surface treatment and modification processes, the surface roughness of the TBC bonding layer (MCrAlY) prepared by a plasma spraying method is reduced through high current pulsed electron beam irradiation, and the pores and holes of a coating are reduced, so that the high-temperature oxidation resistance of the TBC bonding layer is improved. Technical conditions are that vacuum degree is 3.5*10<-2>Pa, voltage is 15kV, frequency is 1Hz, pulse width is 50 to 200mu s, energy density is 8 to 18J / cm<2>, and pulse times is 10 to 20. The method has the advantages that the surface roughness of the TBC bonding layer (MCrAlY) prepared by the plasma spraying method is reduced through high current pulsed electron beam irradiation, the pores and holes of the coating are reduced, and penetrated microcracks are avoided, so that the high-temperature oxidation resistance of the TBC bonding layer is effectively improved.

Owner:DALIAN UNIV OF TECH

Detection kit for ischemia modified albumin

ActiveCN103760357AImprove binding efficiencyGuaranteed accuracyDisease diagnosisColor/spectral properties measurementsNormal albuminMedicine

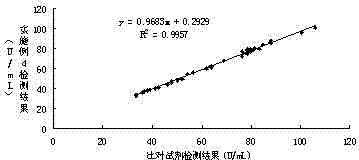

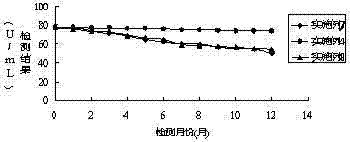

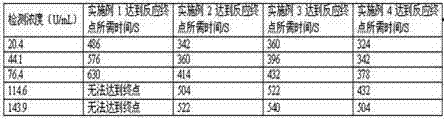

The invention relates to the technical field of detection of ischemia modified albumin content, and in particular to a detection kit for ischemia modified albumin. The kit includes a reagent 1 and a reagent 2. The reagent 1 contains a buffer, cobalt chloride, a stabilizer and a preservative; and the reagent 2 contains a buffer, dithiothreitol, a stabilizer, a reducing protective agent and a preservative. The kit can accelerate the binding efficiency of cobalt ions with normal albumin, and the cobalt ions fully integrate with normal albumin in a certain period of time, so as to ensure the accuracy of the detection result on a sample by the reagent; the kit protects the stability of dithiothreitol in the solution, and does not affect the binding of dithiothreitol with cobalt ions, so as to ensure that an open reagent bottle can be stably kept in a dark place for 30 days at room temperature and a closed reagent bottle can be stably kept at 2-8 DEG C for 12 months, and fully meet the needs of clinical laboratory; and the kit accelerates the combination of dithiothreitol with cobalt ions, so that the reagents reach reaction endpoints as soon as possible, thereby ensuring the efficient detection effect of reagents and significantly improving the accuracy of reagent detection.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

Deplating solution for removing nickel on cooper surface, preparation method thereof, and method for removing nickel on cooper surface

The invention provides a deplating solution for removing nickel on cooper surface. The deplating solution contains water solutions of following components: 100 to 200 g / L of sulfuric acid, 50 to 200 g / L of hydrogen peroxide, 90 to 270 g / L of ethene diamine, 5 to 50 g / L of cysteine, and 1 to 10 g / L of sulfamic acid. The invention also provides a preparation method of the deplating solution, and a method for removing nickel on cooper surface by using the deplating solution. The deplating solution provided by the invention is capable of carrying out a process on a tool to be deplated at a room temperature, barely no volatile irritant gas is generated during the deplating process, so the deplating solution is very environment-friendly; and at the same time, the quality and thickness of the copper layer, and the combining force between the copper layer and subsequent coating are not affected.

Owner:BYD CO LTD

Gene sequencing method

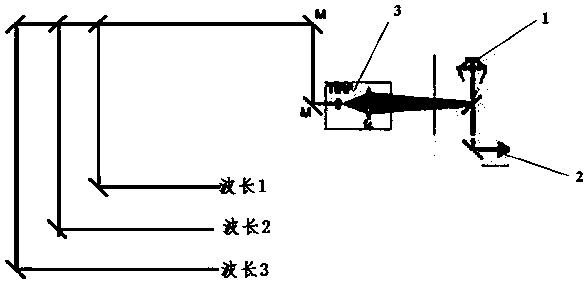

ActiveCN103866010ADoes not affect bindingThe synthesis steps are simpleMicrobiological testing/measurementNucleotideA-DNA

The invention discloses a gene sequencing method. The gene sequencing method comprises the step of exciting three fluorescently-labeled nucleotide molecules by utilizing three different wavelengths of laser, wherein the nucleotide molecules are any three of A, C, G and T nucleotide molecules, the fourth nucleotide molecule has fluorescent nucleotide label. A sequencer is defined again by taking non-fluorescence excitation as a label through the method, so that the method is a method for sequencing synthesized sides by adopting tricolor fluorescent sides. The synthetic steps of the method are simplified, and an imaging device is simple, and low in cost; only three fluorescently-labeled nucleotide molecules are adopted, each sequencing period cannot leave excessive residual molecules on a DNA (deoxyribonucleic acid) chain, the combination of DNA polymerase and to-be-detected DNA chain cannot be influenced, and the sequencing accuracy and reading length can be greatly improved.

Owner:伯科生物医学科技(无锡)有限公司

Method for preparing light-emitting materials

The invention relates to a method for preparing light-emitting materials, which comprises the following steps: carrying out pre-film coating treatment on aggregates, then adding bonding agents and light-emitting materials and / or reflective materials, and evenly stirring, thereby obtaining the light-emitting materials. The light-emitting materials can be used for manufacturing light-emitting bricks or be used for paving a pavement for forming the light-emitting pavement and the like. The light-emitting materials and products thereof have excellent abrasion resistance and light-emitting performance.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

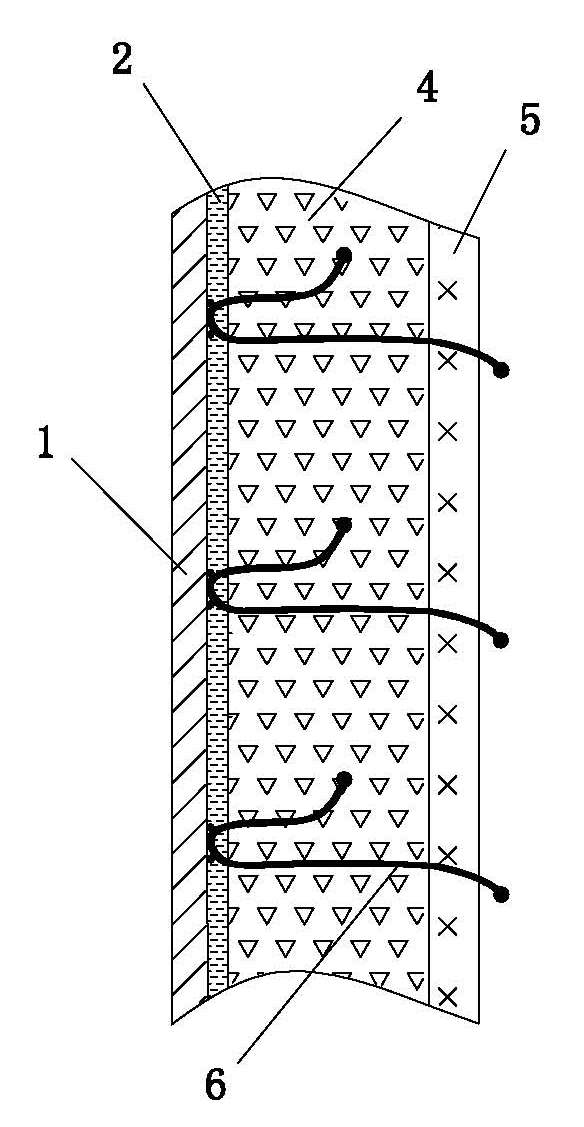

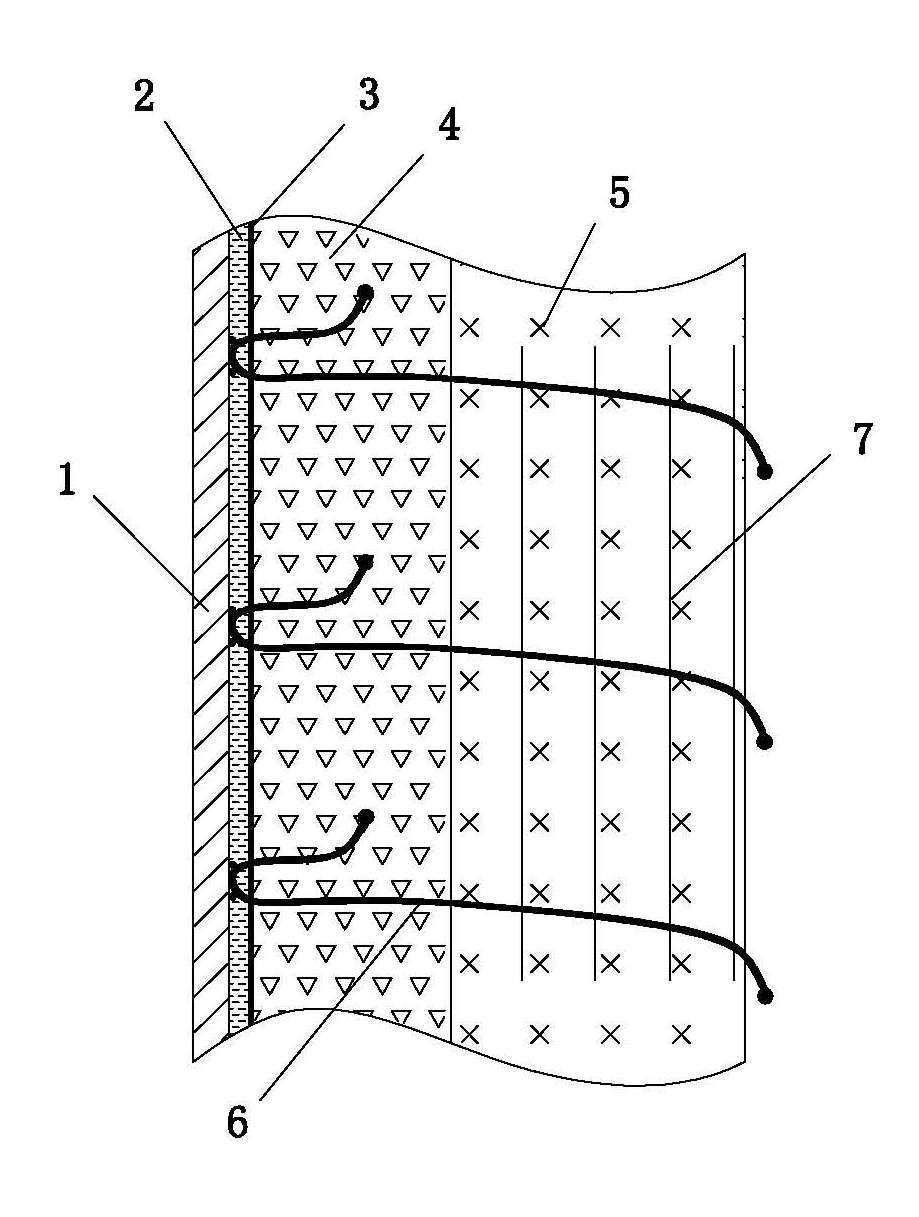

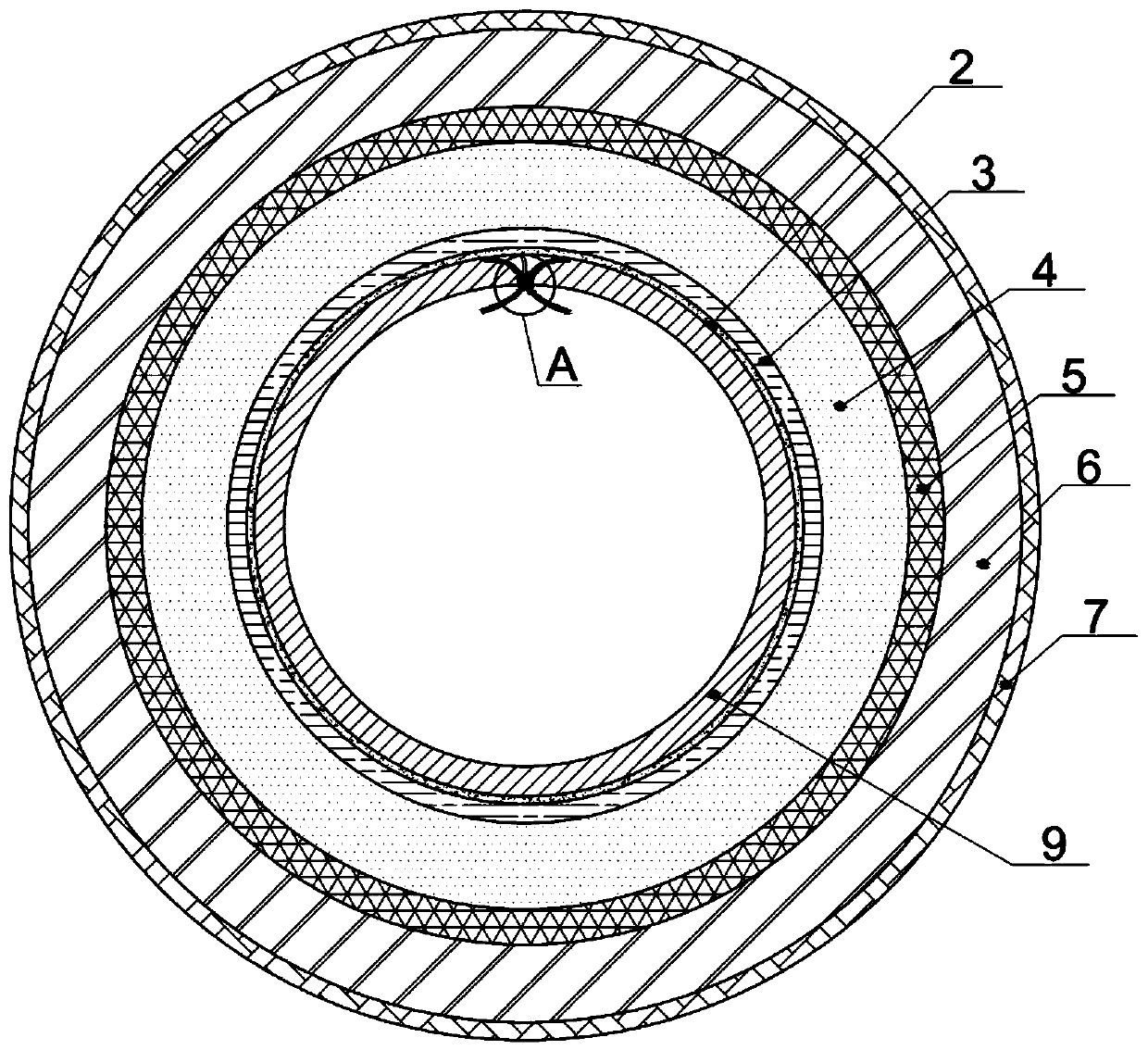

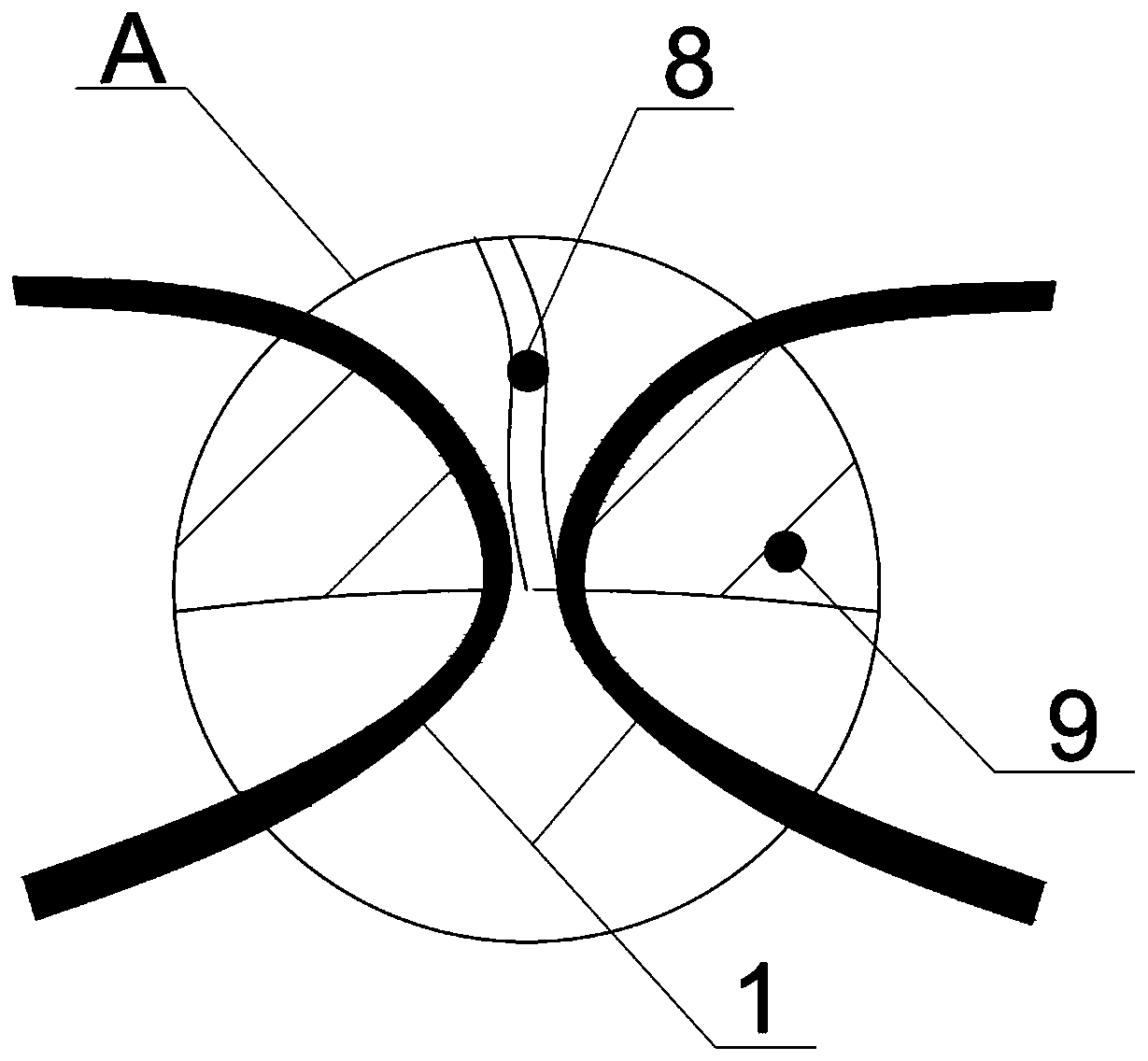

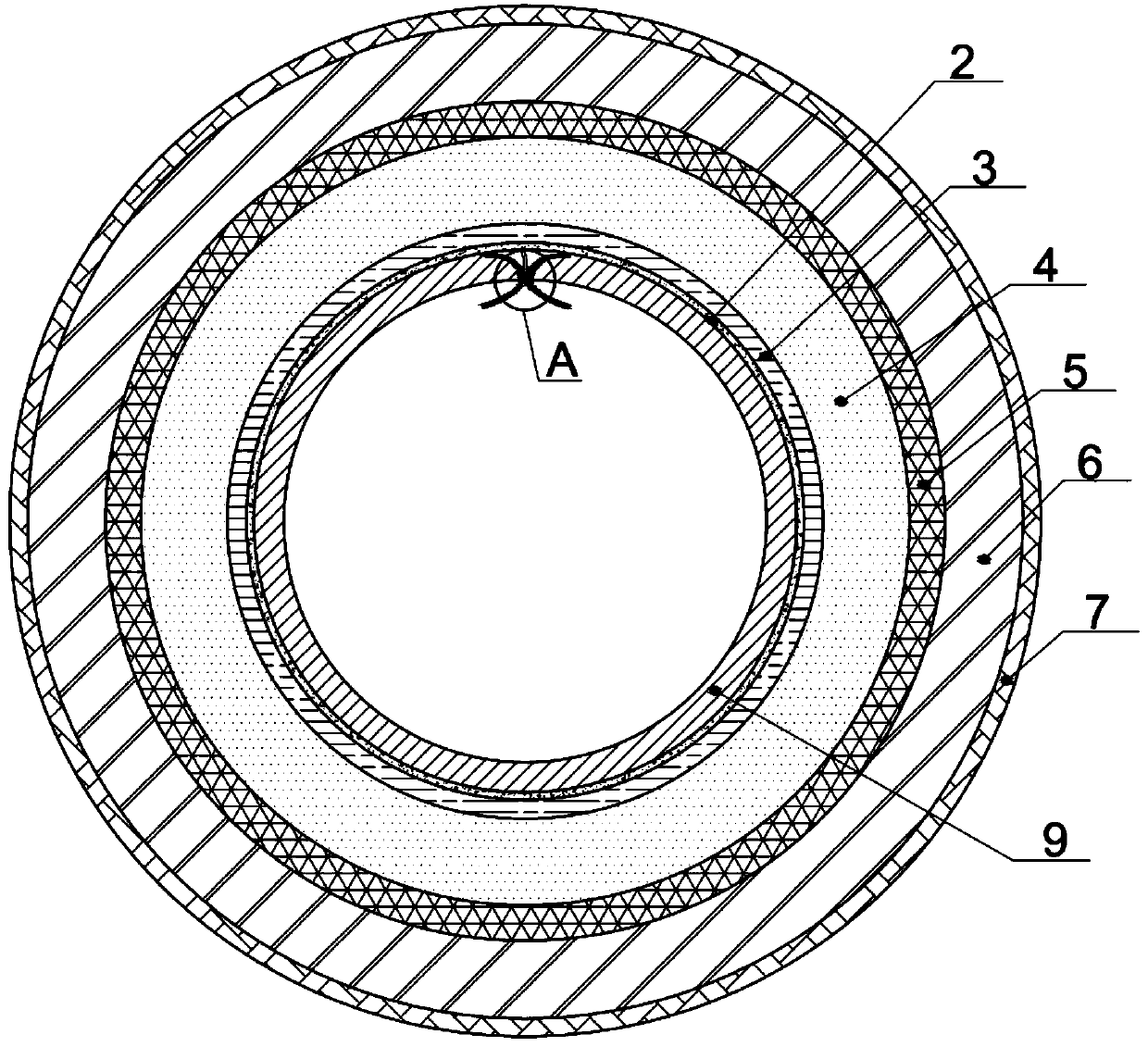

High-temperature-resisting anti-corrosive thermal-insulation composite lining structural member and manufacturing method thereof

The invention discloses a high-temperature-resisting anti-corrosive thermal-insulation composite lining structural member and a manufacturing method thereof. The high-temperature-resisting anti-corrosive thermal-insulation composite lining structural member comprises a metal shell, a light thermal-insulation lining material layer, a cellucotton layer and an anchor nail, further comprises a dew-point corrosion preventing coating layer, and can also comprise high-temperature-resisting alloy-steel wires and a high-temperature-resisting fiber paper layer. The manufacturing method comprises the following steps of welding and fixing the head of the anchor nail on the inner wall of the metal shell body, blade-coating the dew-point corrosion preventing coating layer, applying the light thermal-insulation lining material layer, and spray-coating the cellucotton layer. According to the invention, a composite lining layer is formed by the dew-point corrosion preventing coating layer, the light thermal-insulation lining material layer and the cellucotton layer through a special structure, which play the roles of resisting high-temperature, preventing dew-point corrosion and insulating heat simultaneously, and ensures that the composite lining layer can be combined with a shell body of a thermal facility into a firm integer; meanwhile, the composite lining structural member has better strain property on expansion on heating and contraction on cooling, and makes petrochemical thermal power equipment be used for a long time in the reliable and economical premise.

Owner:陈海渊

Plugging agent for under-pressure plugging repair and construction method of plugging agent

InactiveCN111574954AImprove toughnessEasy curingNon-macromolecular adhesive additivesPipe elementsEpoxyFiber

The invention discloses a plugging and reinforcement material for under-pressure plugging repair and a construction method, and belongs to the technical field of surface engineering; a plugging blockis adopted to perform plugging repair on a corrosion pit hole in a pipeline; the repaired part is reinforced by adopting fast-curing special epoxy repair resin with excellent corrosion resistance anda carbon fiber felt; the repaired part and the pipeline form a whole after being reinforced, and the combination between the plugging reinforcing layer and the pipeline is not influenced by normal vibration during normal operation and occasional vibration with certain strength; sulfydryl in the component A of the plugging agent can react with epoxy groups in the component B of the plugging agent,so a polymer containing a secondary hydroxyl group and a thioether bond is generated; tertiary amine and other amine compounds have a strong promotion effect on the reaction, the reaction rate is muchfaster than the reaction rate of amine and epoxy groups, and the reaction can be carried out at low temperature and even at 0 DEG C; the alkaline energy of the amine promoter is increased to increasethe reaction rate, and toughening and curing of epoxy resin can be promoted.

Owner:青岛海弗莱安全科技有限公司

Pipeline under-pressure leakage stoppage repairing and multiple-layer long-acting anti-corrosion device and construction method thereof

ActiveCN111520570AFree from corrosion damageDoes not affect bindingAntifouling/underwater paintsPaints with biocidesSurface engineeringInsulation layer

The invention discloses a pipeline under-pressure leakage stoppage repairing and multi-layer long-acting anti-corrosion device and a construction method thereof and belongs to the technical field of surface engineering. A six-layer protection system including a leakage stoppage and strengthening layer, anticorrosive paste, an inflaming retarding anti-corrosion belt, an oily blocking layer, an anti-corrosion protection cover and a contamination-preventing and weather-proof face coating is adopted, due to the extremely good tracing ability of the six-layer protection system, the six-layer protection system can be tightly combined with a base material, a protection film composed of the anticorrosive paste and the inflaming retarding anti-corrosion belt and surface oxide of the base material can be subjected to complexation so as to prevent secondary corrosion, meanwhile, the erosion of a corrosive medium on the base material is isolated, sealing protection on anti-corrosion components isachieved through an external oily material insulation layer and the nonmetal protection cover, it is ensured that the anti-corrosion components are not lost, the contamination-preventing face coatingof the inflaming retarding nonmetal protection cover has prominent dirt-preventing performance and good weather-resisting performance, and a permanent outer protection function is provided for the protection cover.

Owner:青岛海弗莱安全科技有限公司

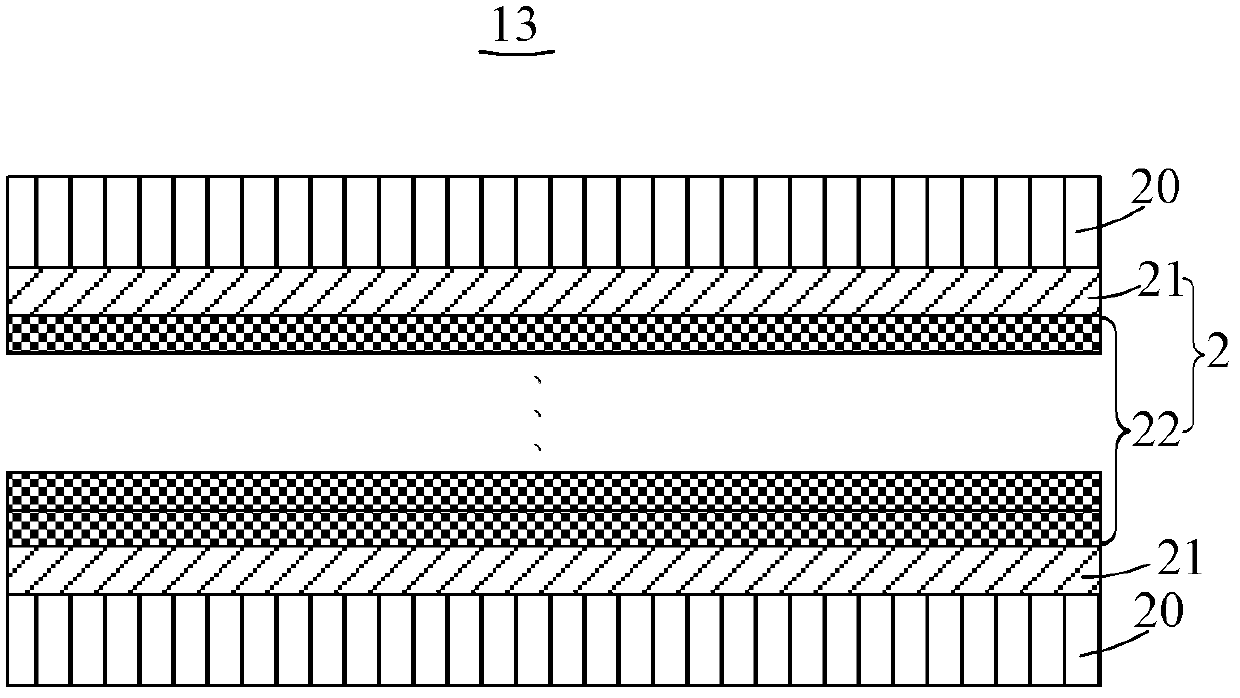

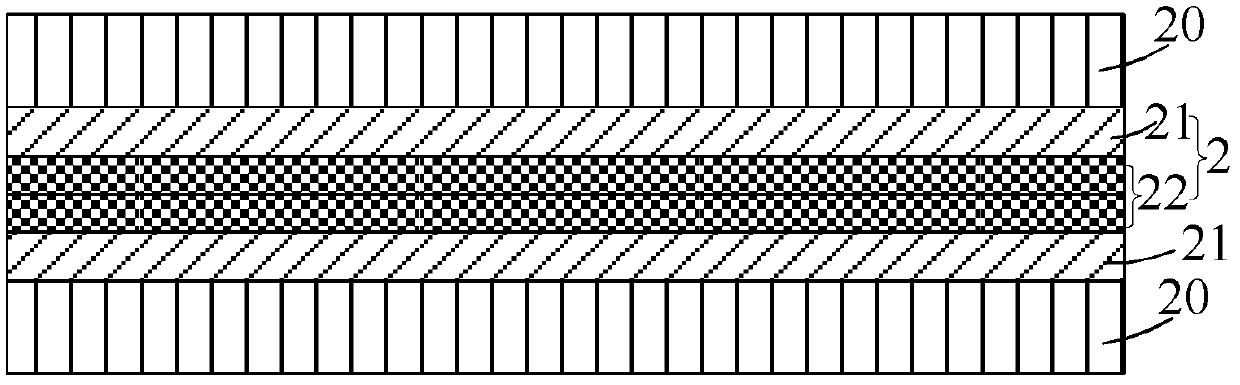

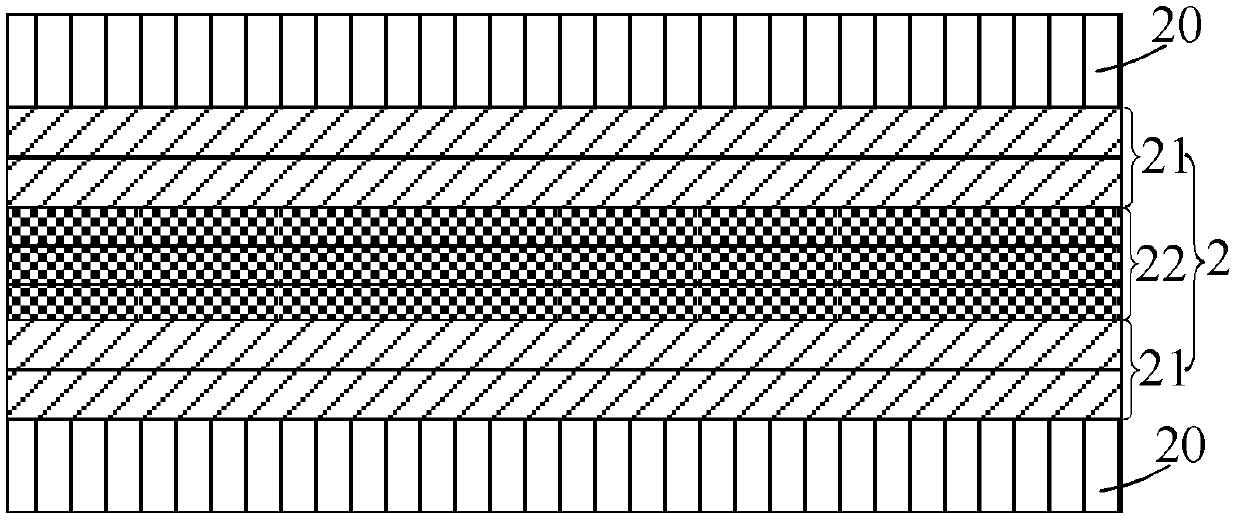

Copper foil layer-clad laminate and preparation method thereof

ActiveCN103287016AHigh dielectric constantDoes not affect bindingLaminationLamination apparatusCopper foilHot press

The invention discloses a copper foil layer-clad laminate. The copper foil layer-clad laminate comprises a mixed curing layer formed by hot-pressing a plurality of prepregs, and a copper foil attached to at least one side of the mixed curing layer, wherein the mixed curing layer comprises at least one first type of prepreg and one second type of prepreg, the first type of prepreg and the second type of prepreg comprise the glass fiber cloth and resin component, and the resin content in the second type of prepreg is less than that in the first type of prepreg. Through the overlaying and laminating of the first type of prepreg and the second type of prepreg, the resin content in the first type of prepreg is greater than that in the second type of prepreg. While maintaining that the resin content of the first type of prepreg is equal to that of the existing copper foil layer-clad laminate, the first type of prepreg and the copper foil are laminated on each other, and therefore, the dielectric constant of the whole copper foil layer-clad laminate is effectively improved without influencing the adhesion force between the copper foil and the laminate.

Owner:KUANG CHI INST OF ADVANCED TECH

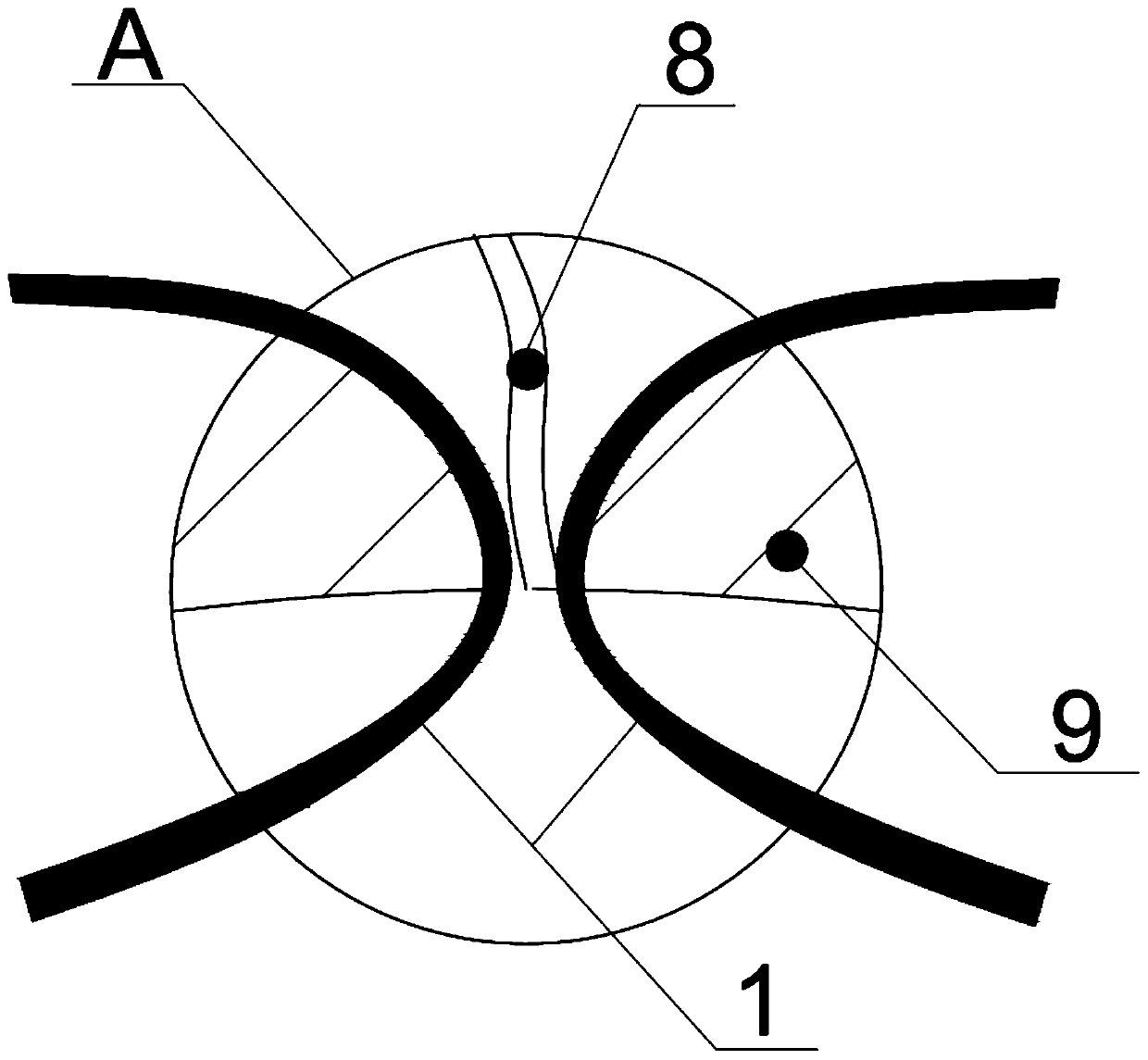

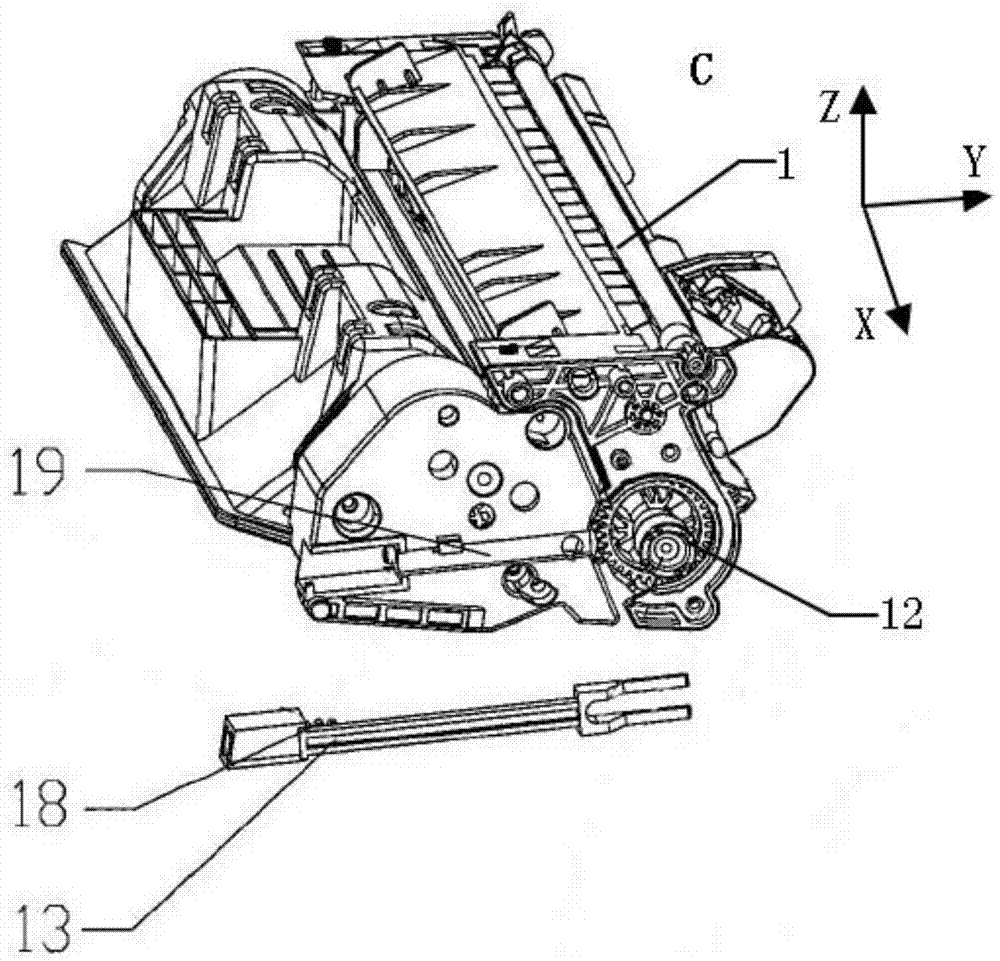

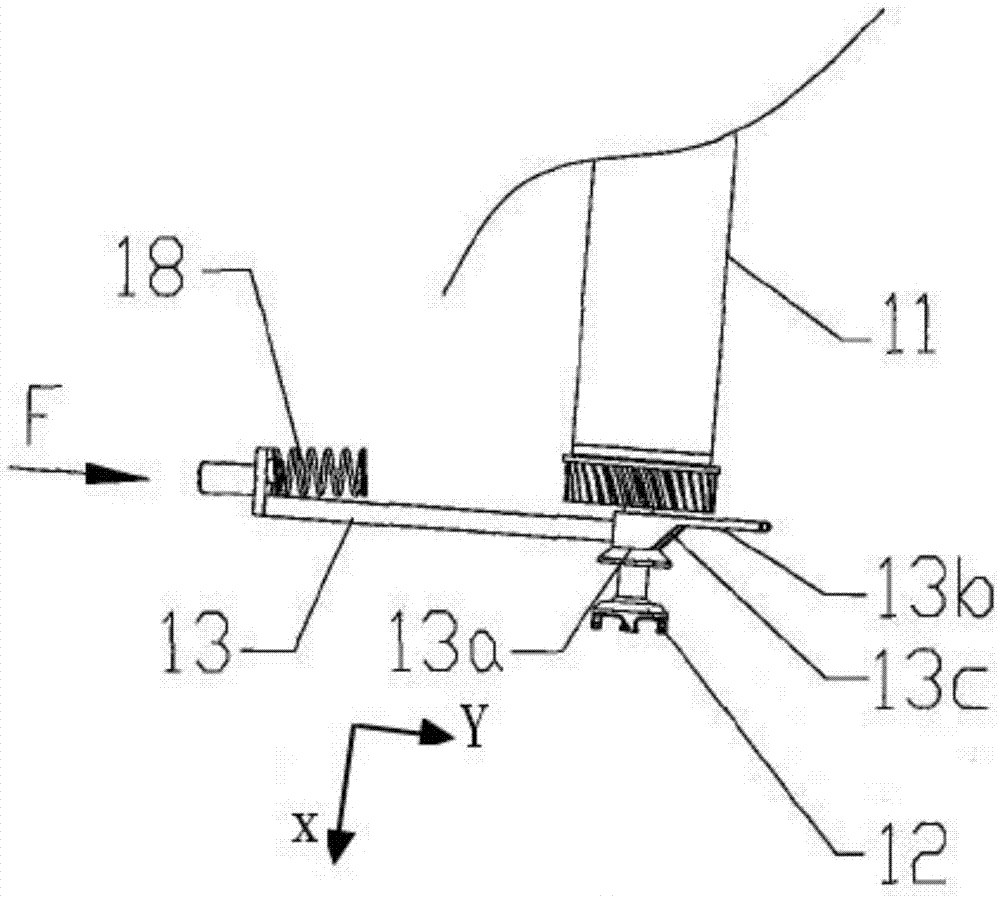

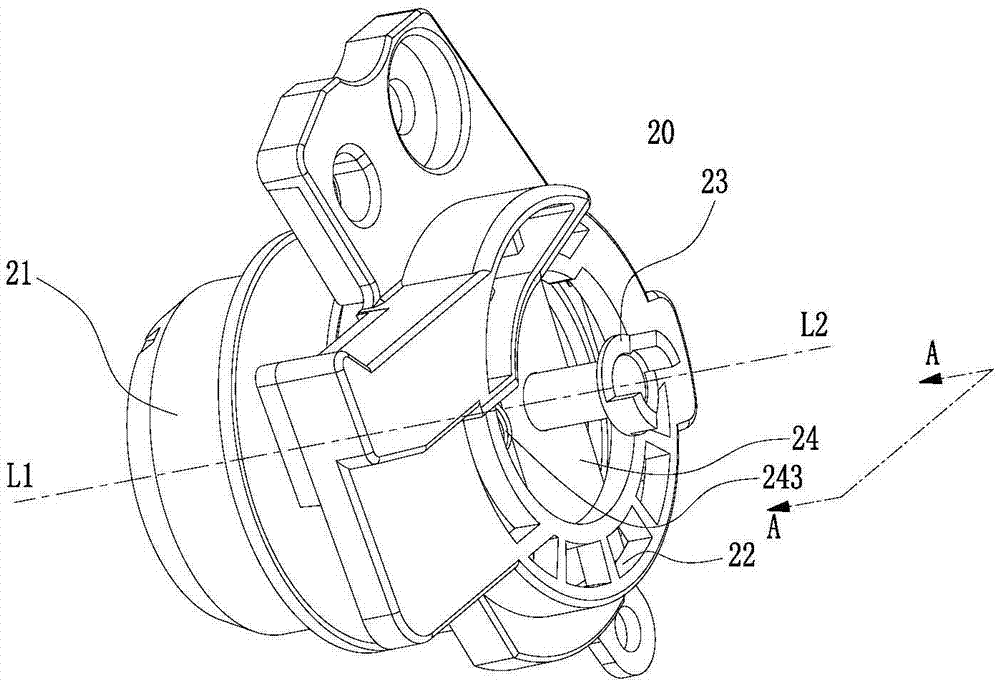

Power transfer device, photosensitive element and processing cartridge

ActiveCN106896686ADoes not affect bindingDoes not affect disengagementElectrography/magnetographyFlangeMoving parts

The invention relates to a power transfer device, and a photosensitive element and processing cartridge having the power transfer device. The power transfer device comprises a flange having a rotation axis L1, a flange bracket, a power receiving part and a power transfer part mounted in the flange, and a moving part, wherein the flange bracket is used for supporting the flange; the power transfer part is mounted in the power receiving part; the power receiving part is penetrated through the moving part; and the moving part is mounted between the flange and the flange bracket. When the power transfer device and a power output device are connected or disconnected, the acting force of a printer door is not needed, thereby effectively ensuring that the photosensitive element or processing cartridge provided with the power transfer device can be widely used.

Owner:ZHONGSHAN KINGWAY IMAGE TECH CO LTD

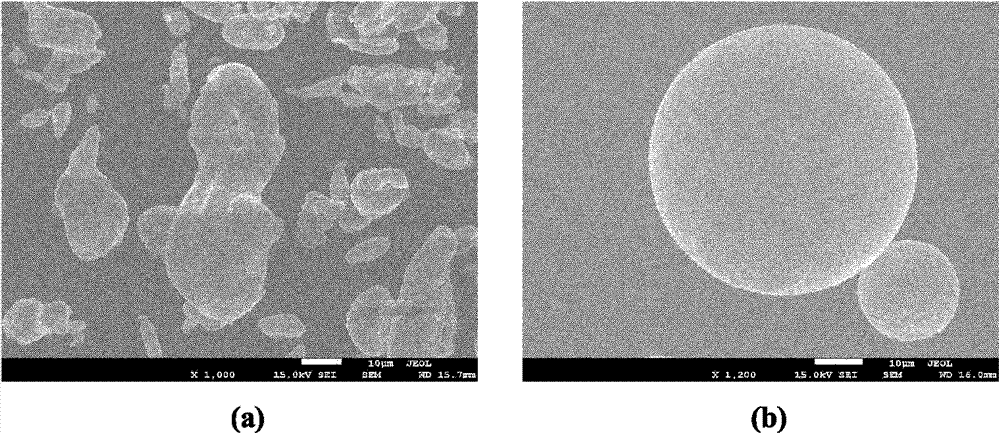

Method for enhancing bonding strength of aluminum coating

InactiveCN102154640BDoes not affect easy recyclabilityHigh hardnessPressure inorganic powder coatingAluminium powderAluminum coating

The invention provides a method for enhancing bonding strength of an aluminum coating, which belongs to the technical field of metal surface treatment; the method comprises the following steps of: aluminium powder and Mg17Al12 spherical powder are mechanically mixed, and the mixed powder is sprayed on the surface of a substrate. In the method, a cold-spraying method is used for depositing the mixed powder of intermetallic compound powder and aluminium powder, and does not worsen other mechanical performances and chemical performances of the aluminum layer while increasing the bonding strengthof the aluminium layer.

Owner:SHANGHAI JIAO TONG UNIV

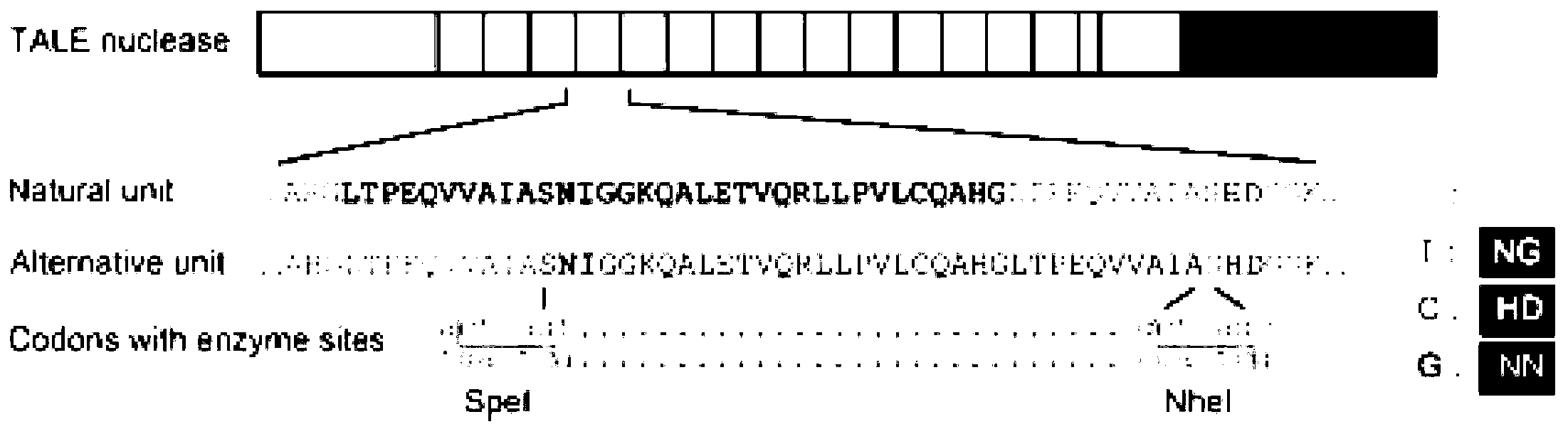

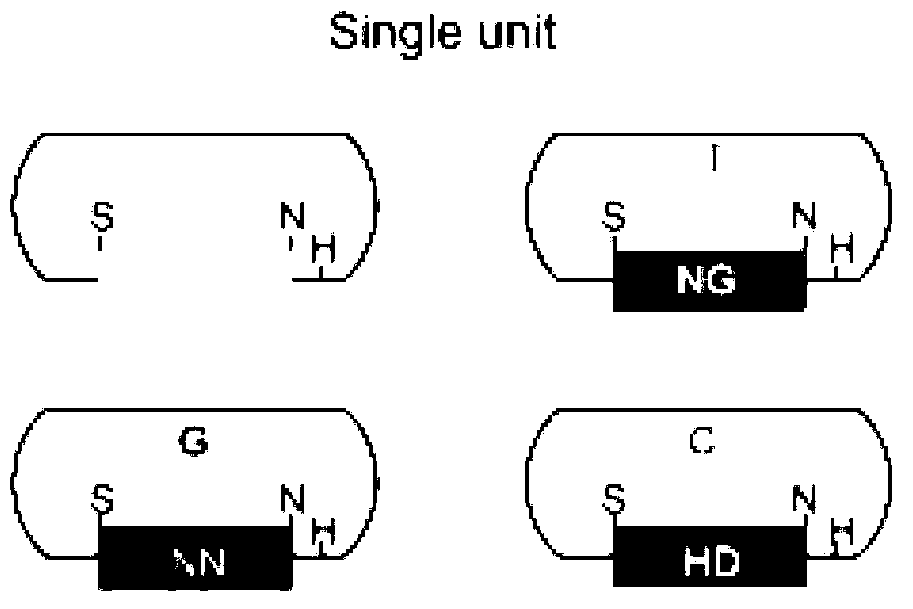

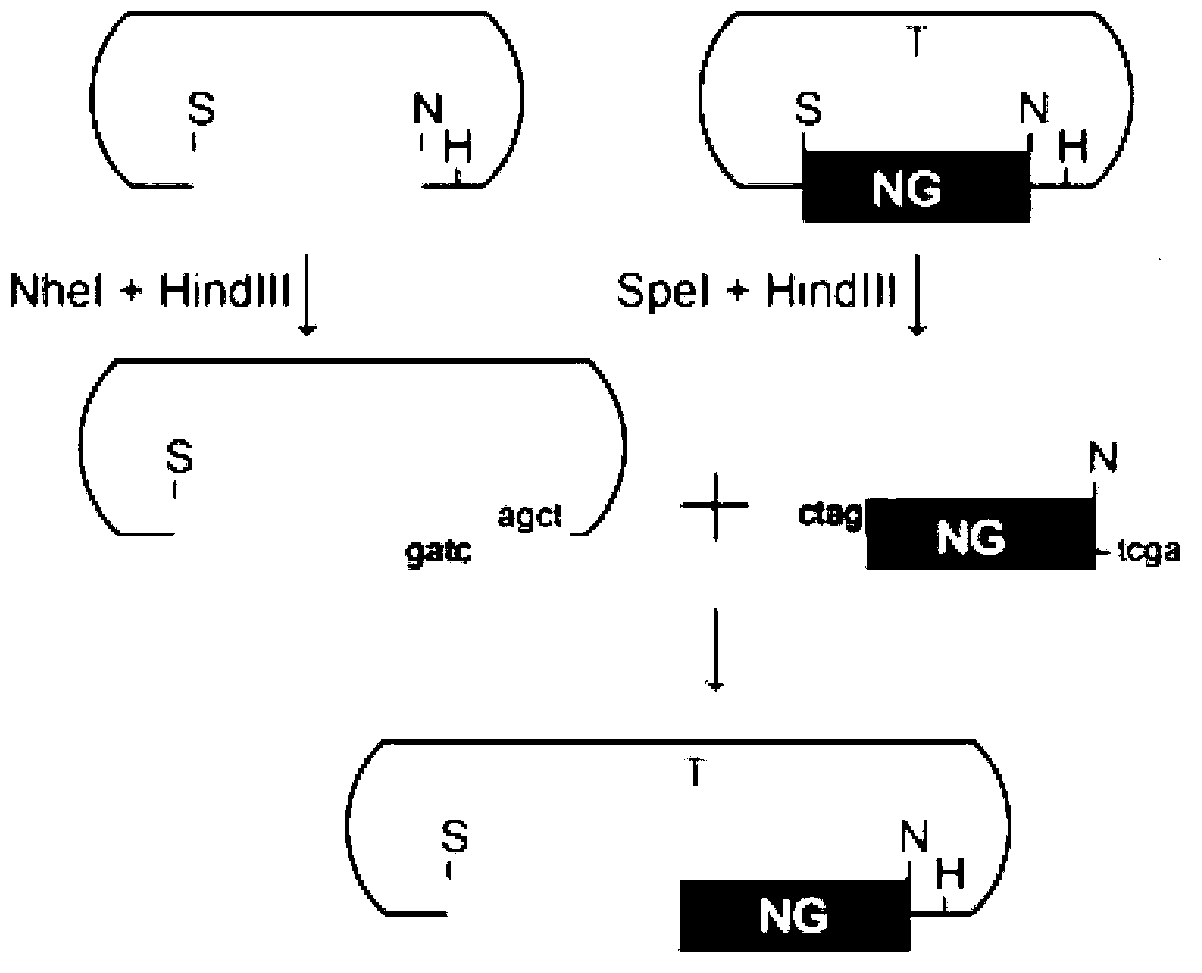

Construction method for gene site-specific mutagenesis in embryonic cell of mouse

InactiveCN102839156ASkip the screening processAvoid irreversible differentiationMicroinjection basedAnimal husbandryCell selectionEmbryo

The invention discloses a construction method for gene site-specific mutagenesis in an embryonic cell of a mouse. A gene site-specific mutagenesis mouse is constructed by introducing a specific nucleotide sequence into the embryonic cell of the mouse. The construction method comprises the following steps: confirming a target sequence in a target genome sequence of the mouse; constructing a TALEN nucleotide sequence capable of identifying and cutting a target gene, according to the sequence of the target sequence; introducing the TALEN nucleotide sequence into the embryonic cell of the mouse; and applying the obtained embryonic cell of the mouse to culture in vitro or directly implanting to a female mouse, expressing the TALEN and cutting the target genome, thereby selecting the gene site-specific mutagenesis mouse. The construction method provided by the invention has the advantages that a homologous recombined target carrier need not be constructed, the ES target cell selection is unnecessary, the mutant proportion is high, the operation is convenient, the test cost and period are greatly reduced, and the like.

Owner:EAST CHINA NORMAL UNIV

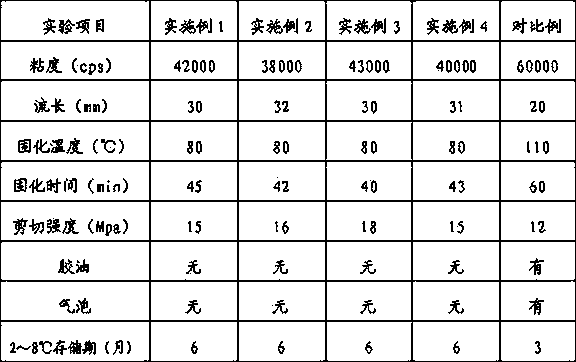

Low-temperature curved high-strength plastic package glue and preparation method thereof

ActiveCN103555247AReduce volatilityHigh strengthNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsLow temperature curingHigh intensity

The invention discloses a low-temperature curved high-strength plastic package glue and a preparation method thereof. The low-temperature curved high-strength plastic package glue comprises the following components in parts by weight: 16-22 parts of bisphenol A epoxy resin, 35-42 parts of bisphenol F epoxy resin, 0.1-1 part of pigment, 10-30 parts of potential hardener, 0.1-1 part of deformer, 10-15 parts of silica powder, 5-10 parts of talcum powder and 5-10 parts of zirconium silicate. The low-temperature curved high-strength plastic package glue provided by the invention has the advantages of low temperature curing (about 80 DEG C), low volatility, high strength, no glue oil, excellent electrical properties and good airtightness, and also excellent storage stability.

Owner:ANTIAN XINBANG XIAMEN ELECTRONICS TECH

Jade green glaze material and firing method thereof

ActiveCN106277792AGuarantee the beautiful color of emeraldDoes not affect bindingChain structureFluorescence

The invention provides a jade green glaze material and a firing method thereof. Ferrous iron is added into a traditional glaze material formula, nitrogen gas is introduced stage by stage in the firing process for protection, it is ensured that the jade color of the glaze material is beautiful, and meanwhile binding of the glaze material and a semifinished product cannot be affected; attapulgite is added, a layer chain structure of the attapulgite is adopted as a template, compounds prepared in the firing process are arranged in order, the reflected color has no variedness, and the color uniformity is quite high; europium oxide is added, the fluorescence property of the europium oxide is utilized, the glossiness of a porcelain glaze material is improved, and the jade-like gleaming sense on the surface of porcelain is improved.

Owner:广东怡泰龙实业发展股份有限公司

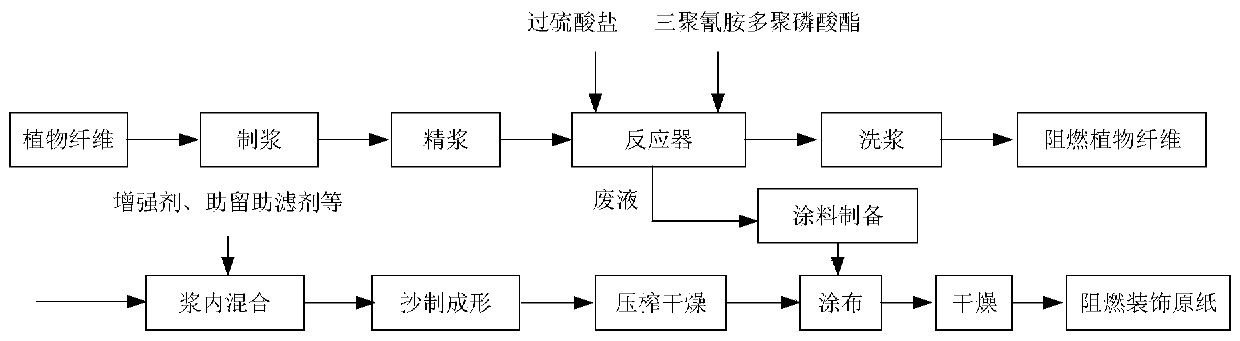

Antiflaming decoration body paper prepared from antiflaming plant fibers, and preparation method thereof

ActiveCN109881528AImprove flame retardant performanceGuaranteed persistenceCellulosic pulp after-treatmentCoatings with pigmentsPersulfateSlurry

The invention relates to antiflaming decoration body paper prepared from antiflaming plant fibers, and a preparation method thereof, and relates to the field of antiflaming materials. The ration of the antiflaming decoration body paper is 45-50g / m<2>, and a limit oxygen index is greater than or equal to 28.5%. The antiflaming decoration body paper disclosed by the invention is prepared in a way that antiflaming plant fibers and paper making accessory ingredients are mixed, copied, squeezed, dried, coated and dried again. The antiflaming plant fibers are prepared in a way that plant fiber slurry is taken as a reaction raw material, melamine polyphosphate is taken as reaction type fire retardant, persulfate is taken as initiator, antiflaming grafting modified reaction is carried out under astirring condition at a temperature of 80-90DEG C and then pulp washing is carried out. The decoration body paper prepared with the preparation method has the advantages of good antiflaming performance, excellent physical performance, and the physical strength of the decoration body paper is not affected while fire resistance is guaranteed. In addition, the antiflaming grafting modified waste liquid is used for preparing antiflamming coating, environment pollution can be lightened, production cost is lowered, and the antiflaming decoration body paper has a wide market prospect.

Owner:杭州华旺新材料科技股份有限公司

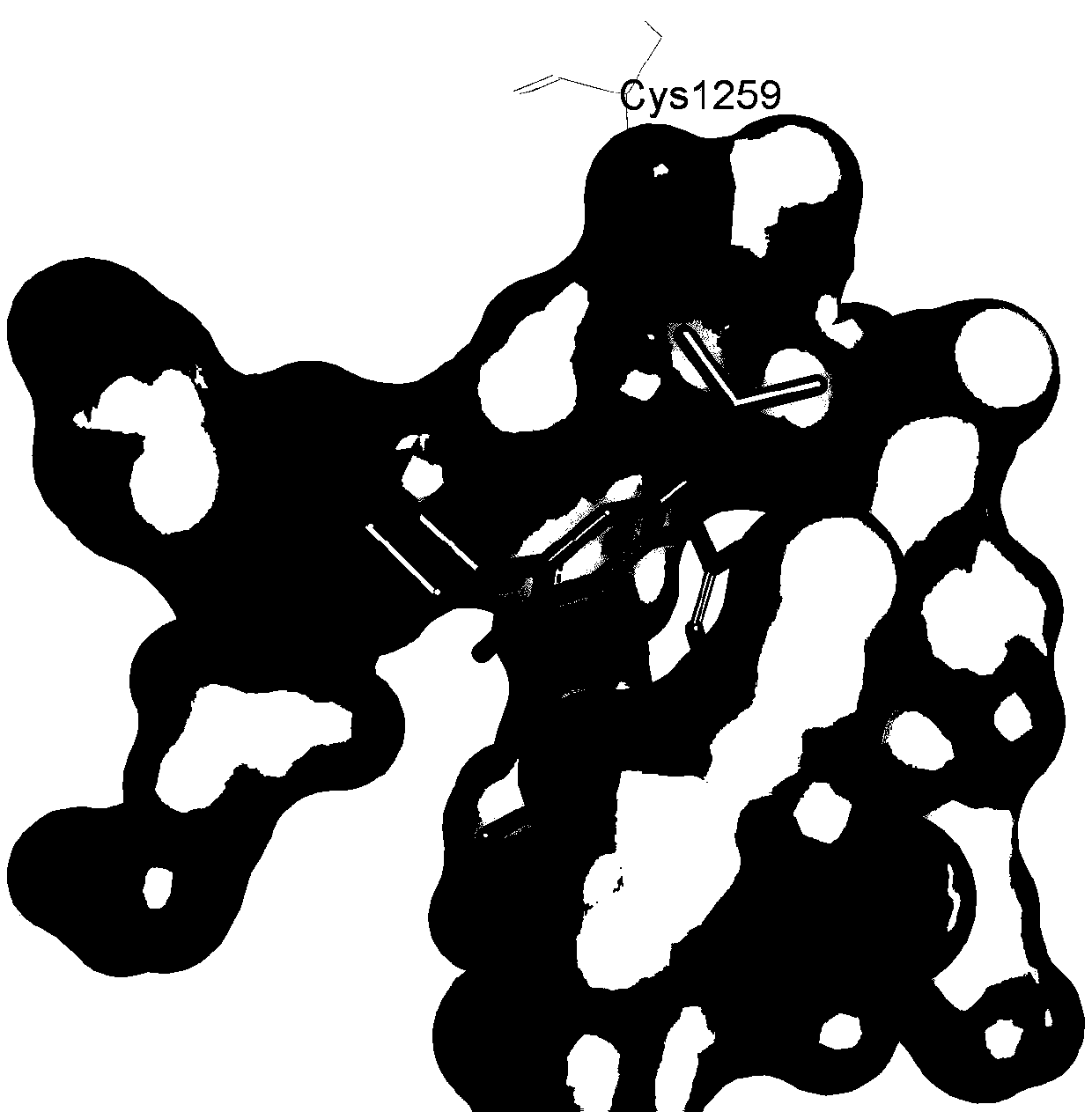

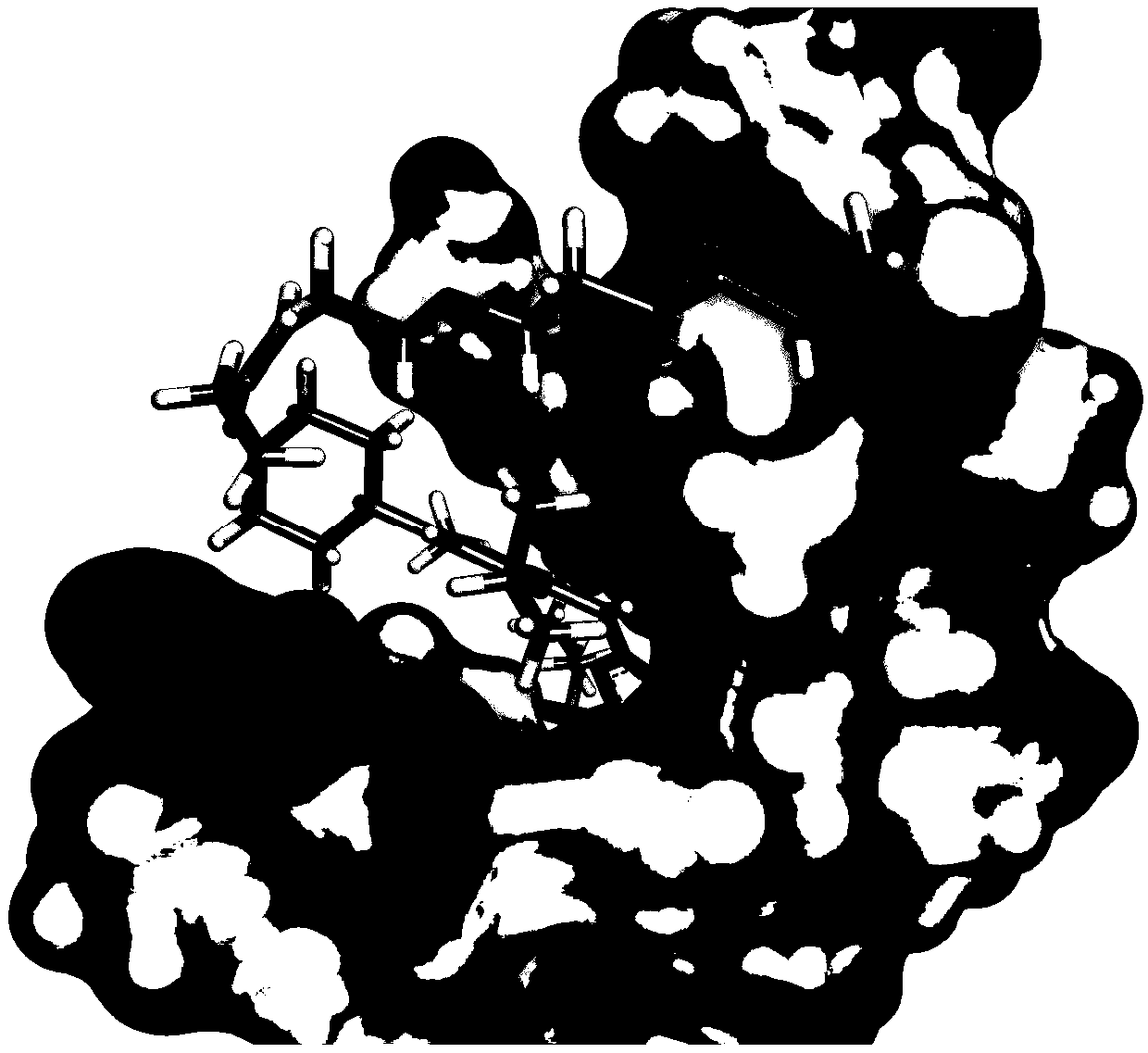

Design method of covalent drugs

ActiveCN110548151ADoes not affect selectivityDoes not affect bindingOrganic active ingredientsPharmaceutical non-active ingredientsProtein targetBinding site

The present invention relates to a design method of covalent drugs and belongs to the technical field of targeted drugs. A technical problem to be solved is providing the design method of the covalentdrugs. The method is primarily to design covalent inhibitors by targeting and binding specific residues at a periphery of a pocket. A main body part of a drug molecule is combined with a binding site, a covalent reaction target head and the specific amino acid residues on the periphery of the pocket form covalent binding, and linker is partially connected with the reaction target head and the main body part. A main structure of the drug molecule is not changed, combination of the main part and the binding site is not influenced, meanwhile, and a covalent bond formed with the specific amino acid residues on the periphery of the pocket can greatly increase binding capacity of the compound molecule and target protein, thereby obtaining lasting and strong biological activity. By using the method, even if no covalent reactive residue exists in the binding pocket, the covalent inhibitors can be developed according to specific amino acids around the pocket, thereby greatly widening design thoughts and application ranges of the covalent drugs.

Owner:SICHUAN UNIV

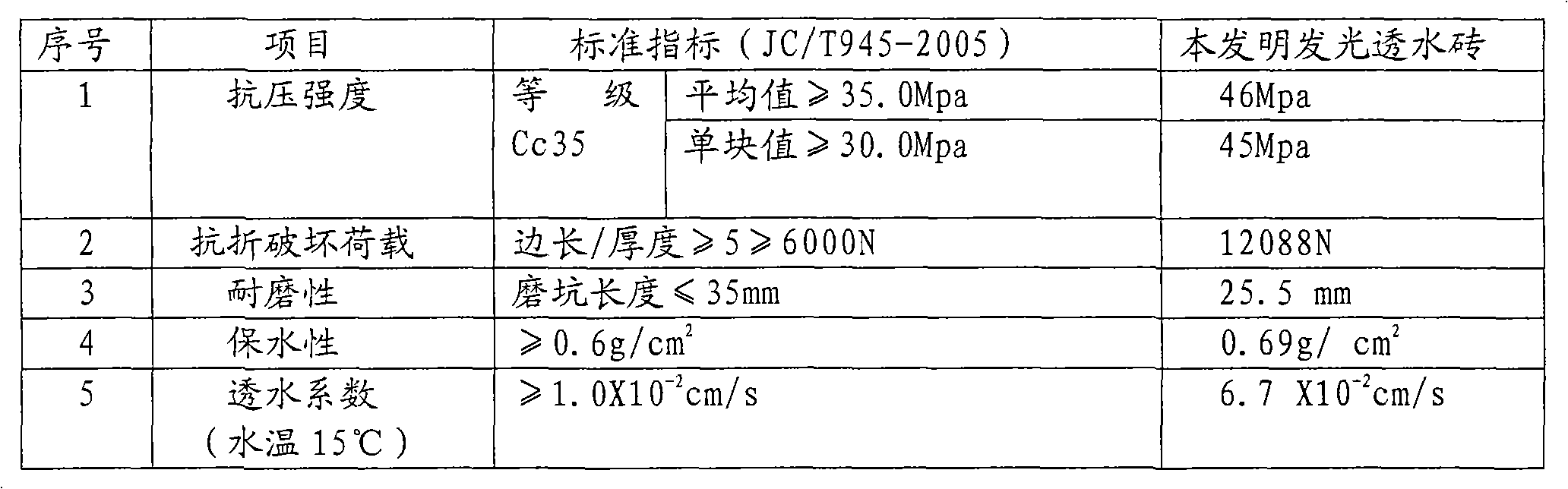

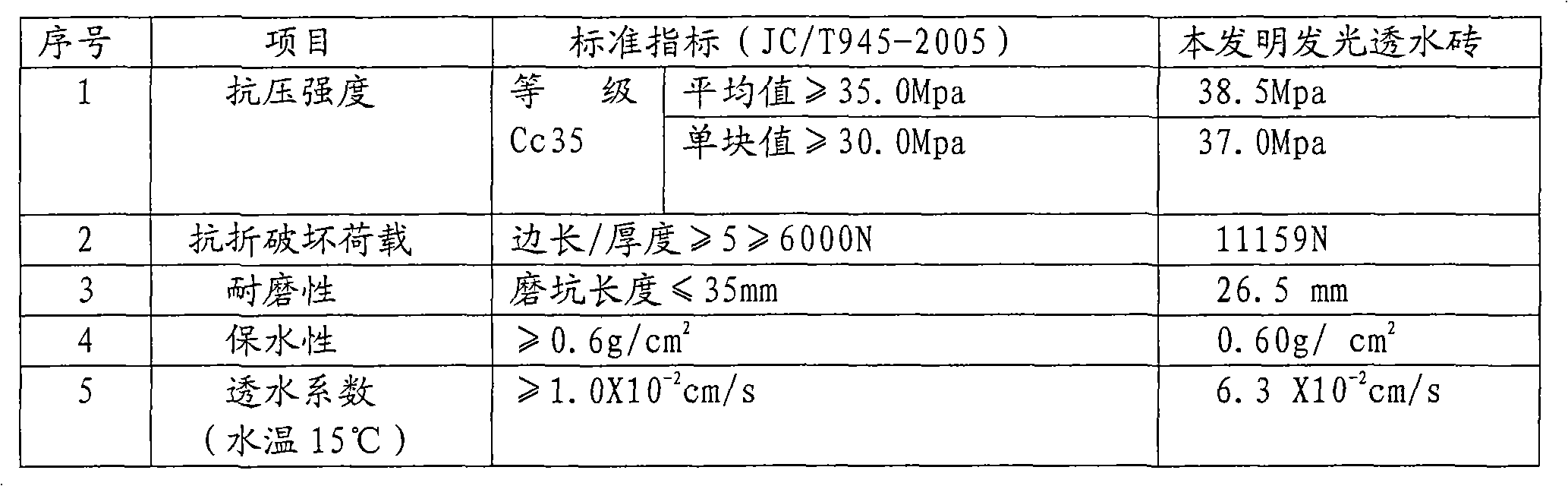

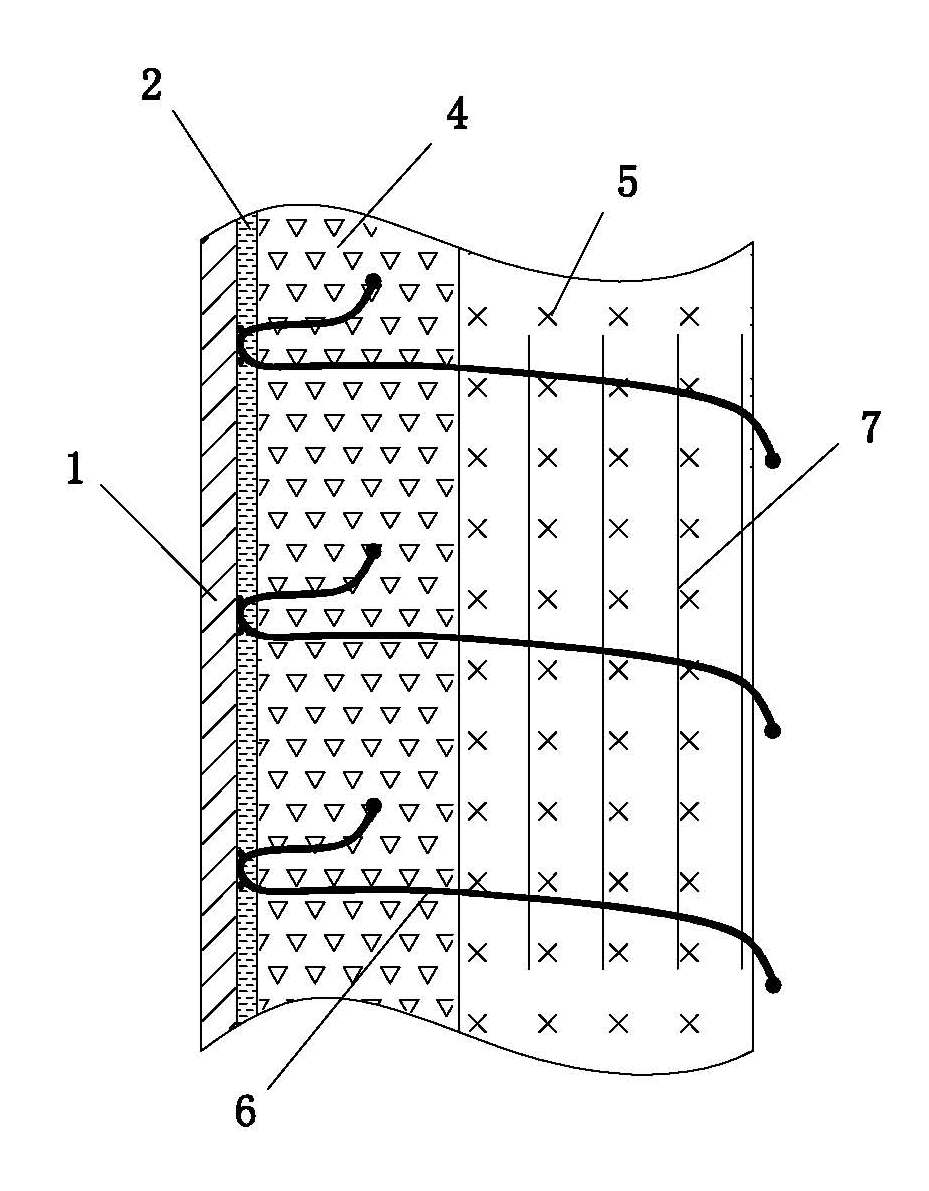

Identification type permeable pavement brick and preparation method thereof

The invention discloses an identification type permeable pavement brick and a preparation method thereof. The identification type permeable pavement brick comprises a permeable base layer and a luminous surface layer; the permeable base layer is prepared from the following components in parts by weight: 390 to 420 parts of cement, 10 to 30 parts of mineral powder, 750 to 850 parts of heavy slag gravel, 800 to 900 parts of heavy slag sand, 1 to 5 parts of a water reducing agent and 210 to 230 parts of water; and the luminous surface layer is prepared from the following components in parts by weight: 20 to 30 parts of film-coated color sand, 1 part of resin, 0.25 to 0.3 part of curing agent, 0.9 to 1.1 parts of light-emitting material, 0.2 to 0.4 part of light-reflecting material and 0.05 to 0.1 part of auxiliary agent. The identification type permeable pavement brick has a colorful effect in the daytime, can absorb sunlight and store light energy, releases the stored light energy in the form of visible light at night, and has good mechanical properties and water permeability.

Owner:中冶武汉冶金建筑研究院有限公司 +1

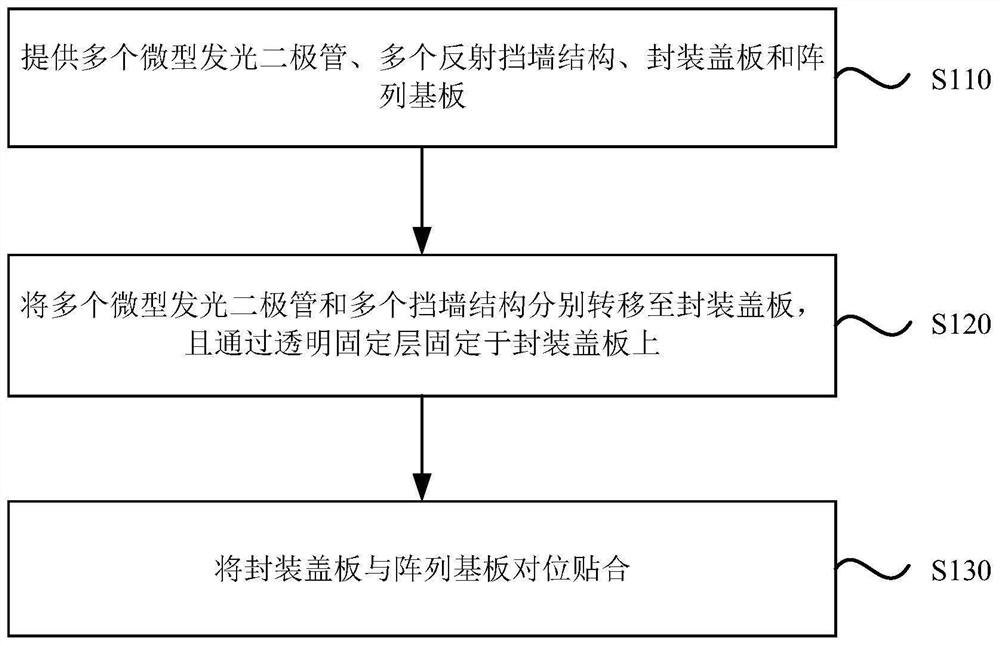

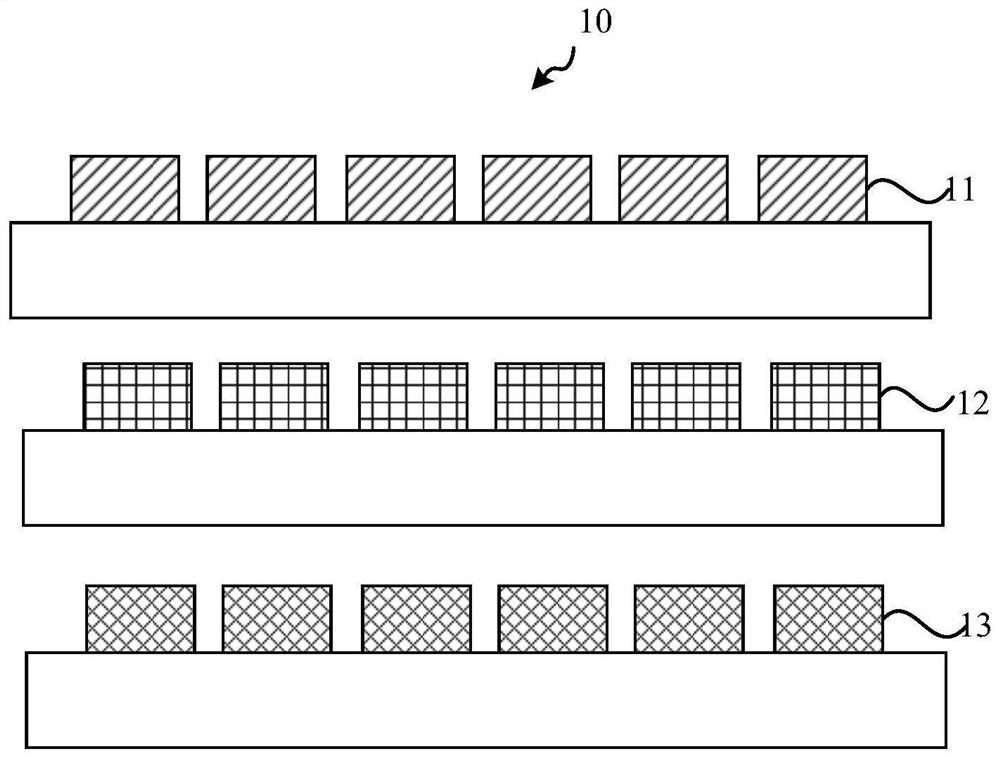

Display panel, preparation method and display device

ActiveCN112786760AReduce manufacturing costIssues that do not affect process yieldSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The embodiment of the invention discloses a display panel, a preparation method and a display device. The preparation method comprises following steps: providing a plurality of micro light-emitting diodes, a plurality of reflection retaining wall structures, a packaging cover plate and an array substrate, wherein the packaging cover plate comprises a cover plate and a transparent fixing layer located on one side of the cover plate; the array substrate comprises a substrate body and a conductive layer located on one side of the substrate body; and the conductive layer comprises a plurality of conductive electrodes; respectively transferring the plurality of micro light-emitting diodes and the plurality of reflection retaining wall structures to the packaging cover plate, and fixing the micro light-emitting diodes and the reflection retaining wall structures on the packaging cover plate through a transparent fixing layer, wherein at least one micro light emitting diode forms a pixel unit and the reflection retaining wall structures are located between the adjacent pixel units; attaching the packaging cover plate and the array substrate in an aligned mode, wherein the attaching mode is that the side, provided with the micro light-emitting diodes, of the packaging cover plate is attached to the conductive layer of the array substrate in an aligned mode, the conductive electrodes are electrically connected with the micro light-emitting diodes in a one-to-one correspondence mode, and the cover plate is reused as a packaging layer of the display panel.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Biological noble metal roast ceramic alloy for oral cavity plerosis

InactiveCN1823700AGuaranteed corrosion resistanceCause side effectsImpression capsDentistry preparationsBiocompatibility TestingAlloy

A biologic noble metal-baked ceramic alloy for repairing tooth contains Au (80-88 Wt%), Pt (9-15), Zn (1-2.2), In (0.2-1.2), Fe (0.2-0.8), Rh (0.2-0.8) and Ir (0.1-0.6). Its advantages are high biocompatibility and anticorrosion nature, no by-effect, not decoloring, and uniform mechanical performance.

Owner:SHANGHAI JIAO TONG UNIV

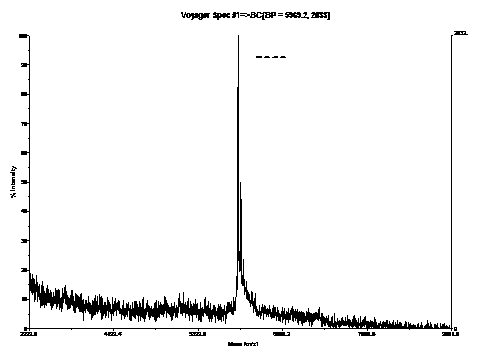

Fuse protein of specific antibody N1M1 and N2M2 and its coding gene

InactiveCN1737146ADoes not affect bindingOvercoming the disadvantage of not being easy to penetrate into tumor tissueImmunoglobulins against cell receptors/antigens/surface-determinantsDNA/RNA fragmentationEscherichia coliNucleotide

Disclosed is a fusion protein of specific antibody N1M1 and N2M2 and its coding gene, wherein the double specific antibody N1M1 fusion protein has amino acid sequence of SEQ ID No:2 in the sequence table, its coding gene has amino acid sequence of SEQ ID No:3 in the sequence table, and the double specific antibody N2M2 fusion protein has amino acid sequence of SEQ ID No:8 in the sequence table, its coding gene has amino acid sequence of SEQ ID No:7 in the sequence table.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

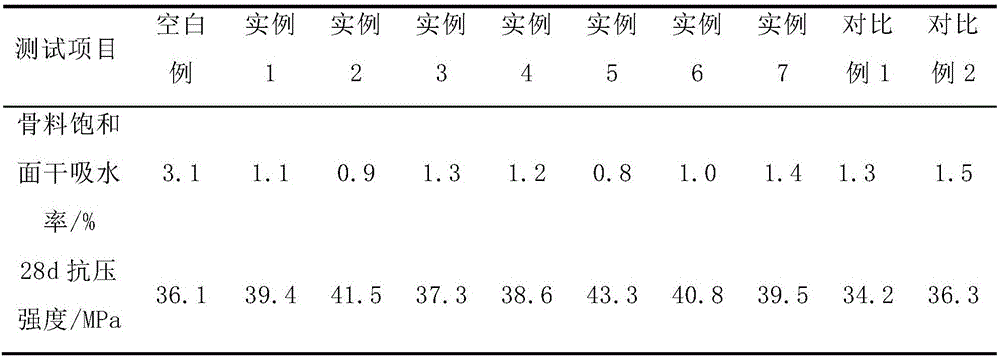

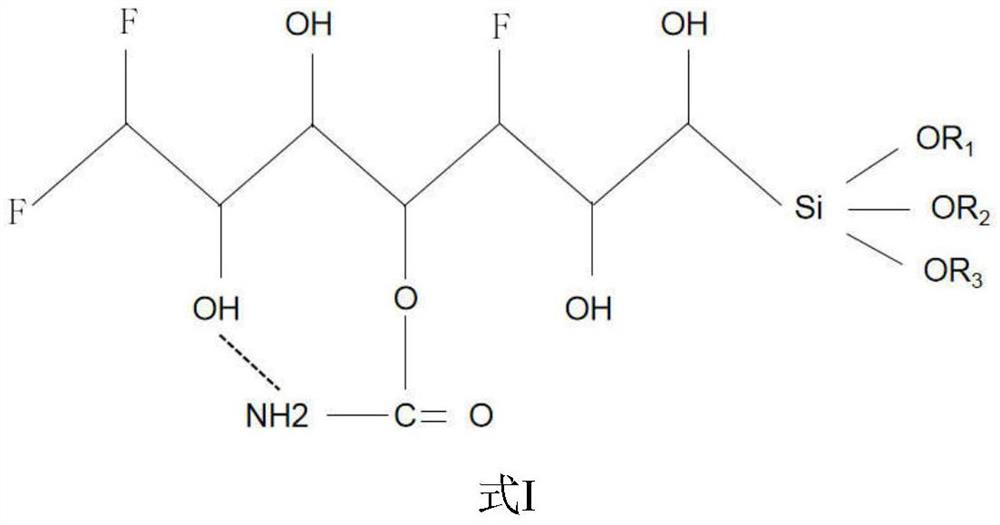

Large-water-absorption-rate aggregate surface treatment agent

The invention relates to a large-water-absorption-rate aggregate surface treatment agent, and belongs to the technical field of high performance concrete; the surface treatment agent is composed of the components by the weight percentage: 10-30% of silica fume, 10-30% of a limestone powder, 10-30% of ultra-fine fly ash, 10-20% of silane, 10-20% of polyvinyl alcohol, 5-10% of a waterproof alloy powder, and 1-5% of a polycarboxylate water reducing agent. The large-water-absorption-rate aggregate surface treatment agent is easy to use; while the water absorption rate of a large-water-absorption-rate aggregate is reduced, the combination of the aggregate and a cement paste in concrete is not affected, the performance of the large-water-absorption-rate aggregate is improved, and the application of the large-water-absorption-rate aggregate is promoted.

Owner:CHINA ROAD & BRIDGE +1

Inhibitor A detection kit and preparation method thereof

InactiveCN109061198AEliminate distractionsReduce dosageBiological testingBiotin-streptavidin complexAcridine

The invention provides an inhibitor A detection kit and a preparation method thereof to solve the problems that an existing inhibitor A detection kit is low in luminescent reaction rate, low in sensitivity, narrow in the linear range, and is high in the cost, and belongs to the technical field of immunodiagnosis. The kit comprises streptavidin magnetic bead suspension, an acridine-labeled inhibitor A antibody and biotin labeled inhibitor A antibody. The invention further provides a preparation method of the inhibitor A detection kit. The detection principle of a reagent is double antibody sandwich method. Detection is conducted by the acridine-labeled antibody and biotin labeled antibody. The luminous rate is increased and the reaction level is expanded. The specificity and detection speedof the reagent are greatly improved.

Owner:DIRUI MEDICAL TECH CO LTD

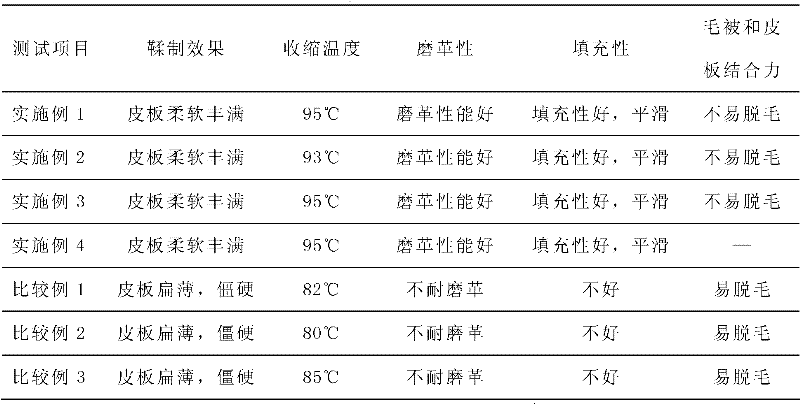

Tanning method for double-face leather

InactiveCN102534058AHigh fullnessHigh temperature resistanceTanning treatmentPre-tanning chemical treatmentInorganic saltsWear resistance

The invention provides a tanning method for double-face leather, which includes conducting soaking processing, softening processing and pickle processing on the double-face leather sequentially; adding inorganic salt, 4-hydroxymethyl phosphine and tanning auxiliaries into mixing solution after pickle processing to obtain a first tanning agent, and using the first tanning agent to conduct main tanning on the double-face leather after the pickle processing; and adding a sulfone tanning agent and protein filler into the mixing solution after the main tanning to obtain a second tanning agent, and using the second tanning agent to conduct retanning on the double-face leather after the main tanning. The double-face leather after the main tanning is not easy to depilate, rich and soft in a leather board and high in thermal contraction temperature, has good abrasion resistance and filling performance, and is especially suitable for being used as leather for shoes, medical treatment and saddles.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE

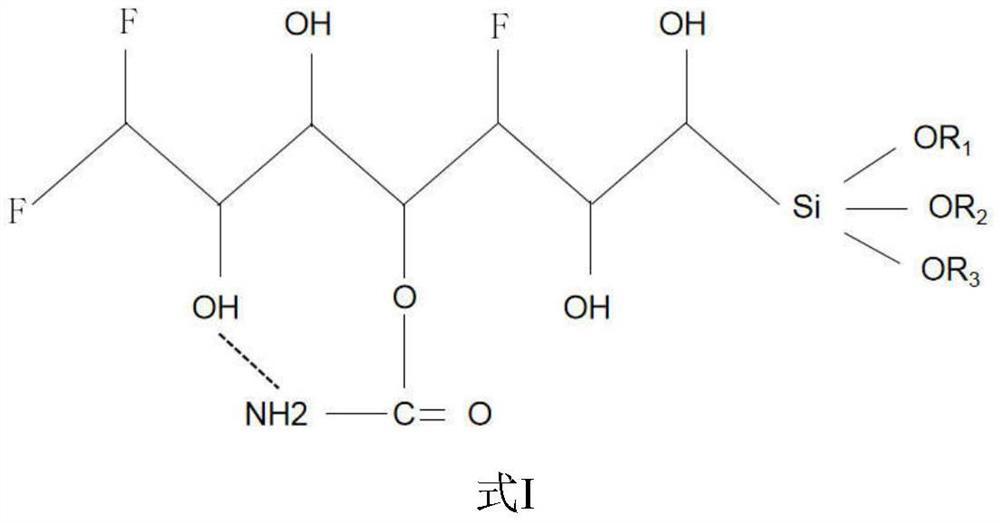

Optical glass surface evaporation process

InactiveCN112358196AImprove product yieldLow production costVacuum evaporation coatingSputtering coatingPlasma treatmentPlasma processing

The invention discloses an optical glass surface evaporation process which comprises the following steps: after cleaning the surface of optical glass, carrying out plasma treatment on the surface of the optical glass to enable the water drop angle value of the surface of the optical glass to be lower than 15 degrees, then evaporating an OC-3001 material on the surface of the optical glass, furthercarrying out plasma treatment, and continuing to evaporate a color film or an antireflection film. The cost of the process is only lower than half of that of a traditional process, the product is manufactured at a time through evaporation, the yield is greatly improved, working procedures are reduced, and the productivity is increased at the same time.

Owner:湖南宏泰新材料有限公司

Urine sulfhydryl compound detection reagent and preparation method thereof

InactiveCN106226295ADoes not affect bindingImprove detection accuracyMaterial analysis by observing effect on chemical indicatorSodium acetateSodium acetrizoate

The invention relates to the field of detection reagents, and in particular relates to a urine sulfhydryl compound detection reagent and a preparation method thereof. The preparation method comprises the following steps: preparing mixed solution of mercury bichloride, magnesium chloride and sodium acetate; preparing mixed solution of phosphotungstic acid, sodium dihydrogen phosphate and sulphuric acid, wherein pH of the mixed solution is 3-5. The detection reagent comprises first mixed solution of bichloride, magnesium chloride and sodium acetate and second mixed solution of phosphotungstic acid, sodium dihydrogen phosphate and sulphuric acid, wherein pH of the second mixed solution is 3-5; when the detection reagent is used, volume ratio of the first mixed solution to the second mixed solution is (1-2):1, and reference solution is distilled water. The detection reagent provided by the invention is convenient in sampling, simple in operation and rapid in report, can detect cervical carcinogenesis at an earlier period and is a preferable detection method.

Owner:SUZHOU RELING BIOTECH CO LTD

Insulating waterproof coating and using method thereof

InactiveCN107286790APromote environmental protectionIncrease elasticityWax coatingsPretreated surfacesPhosphatePhosphoric acid

The invention relates to an insulating waterproof coating, which comprises the following components in mass fractions based on the total weight: 15-20% of acrylate elastic emulsion, 1-2% of partial chlorine emulsion, 5-10% of chlorinated paraffin, Mica powder 1‑5%, talc powder 1‑5%, boron nitride 1‑2%, zirconium nitride 1‑2%, alumina 1‑2%, binder 5‑10%, additive 5‑10 %, the balance is water. The present invention also provides a method for using the insulating waterproof coating, comprising the following steps: coating the insulating waterproof coating on the surface of the base material to form an insulating waterproof layer; coating a layer of phosphoric acid solution of aluminum dihydrogen phosphate on the insulating waterproof layer . The paint of the invention is suitable for various base materials, and can be applied on wet base surfaces without affecting the combination of the insulating waterproof layer and the base surface.

Owner:太仓红潮新材料科技有限公司

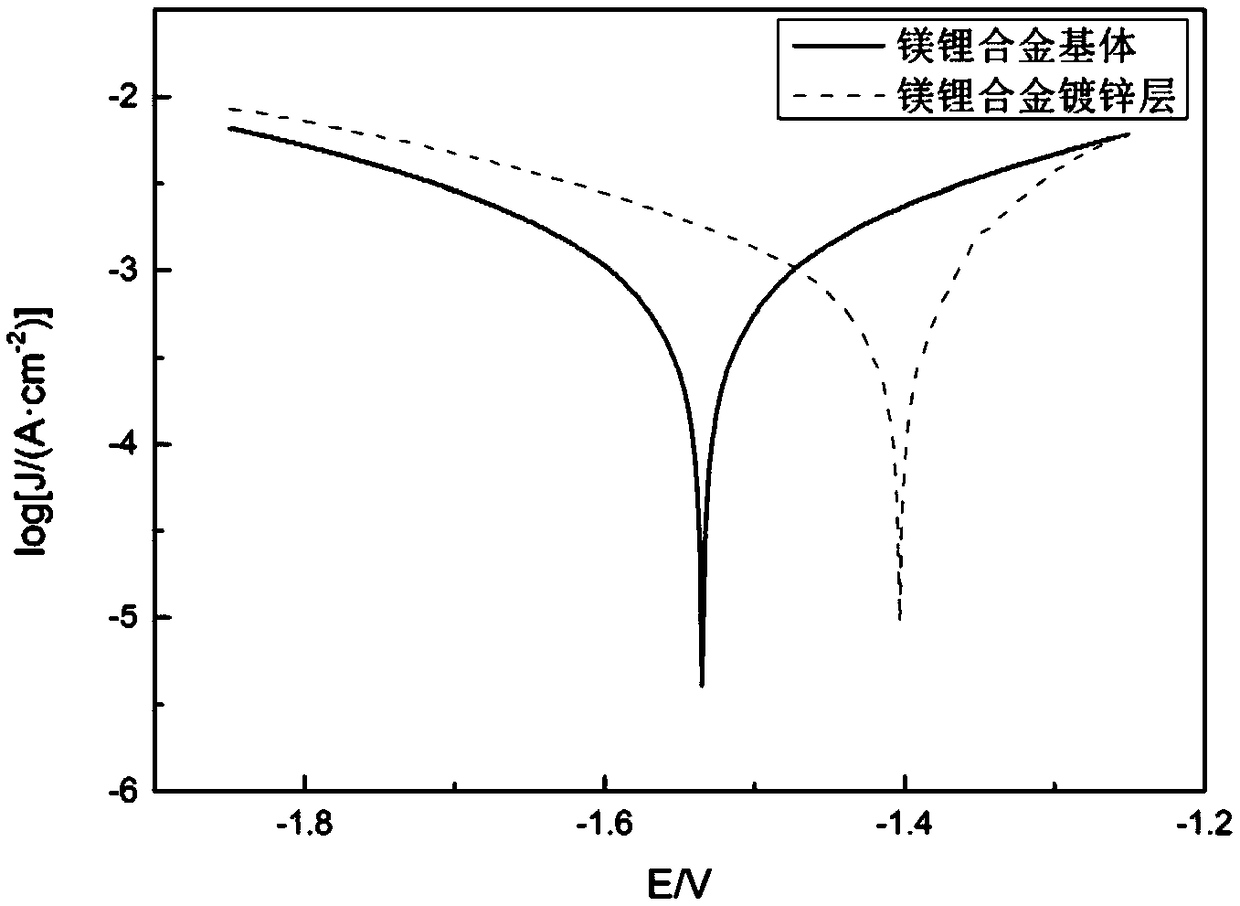

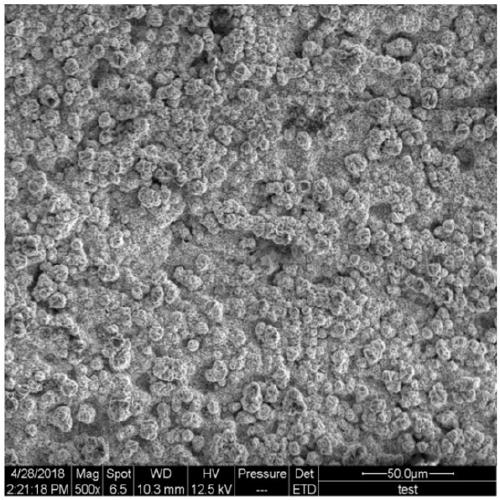

Method for electrogalvanizing on surface of magnesium lithium alloy

The invention provides a method for electrogalvanizing on the surface of magnesium lithium alloy. The method comprises the following steps: polishing, oil removal, etching, activating, zinc immersion,first-time pre-electrogalvanizing, second-time pre-electrogalvanizing and drying. The surface of the magnesium lithium alloy is subjected to electrogalvanizing by an electroplating method, a conventional magnesium alloy surface electroplating pretreatment process is adopted, priming is implemented by a zinc immersion process, then a process of two-time electrogalvanizing is carried out, the binding force of a coating is not affected on the premise of simplifying procedures, the preparation speed of the coating is increased, and the corrosion resistance of the magnesium lithium alloy is improved; and moreover, zinc oxide and zinc sulfate serve as main salts, experimental results are good, moreover, the zinc oxide and the zinc sulfate are non-toxic and tasteless, and are low in price and wide in operation range, and the method belongs to an environmentally friendly process. By the method, the corrosion resistance of the magnesium lithium alloy is improved effectively, the cost is reduced, the method is simple to operate, batch production can be implemented, and moreover, the method can further serve as a pretreatment technology for electroplating of other metals later.

Owner:HARBIN ENG UNIV

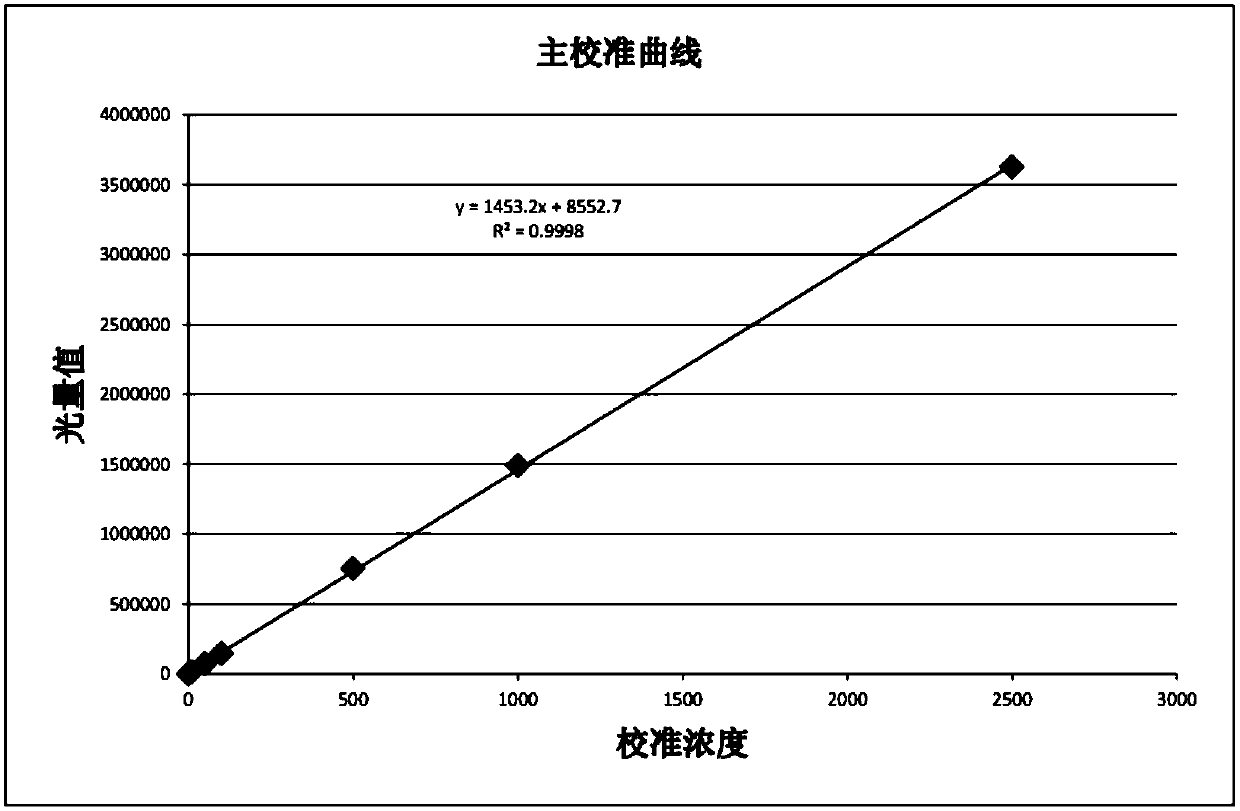

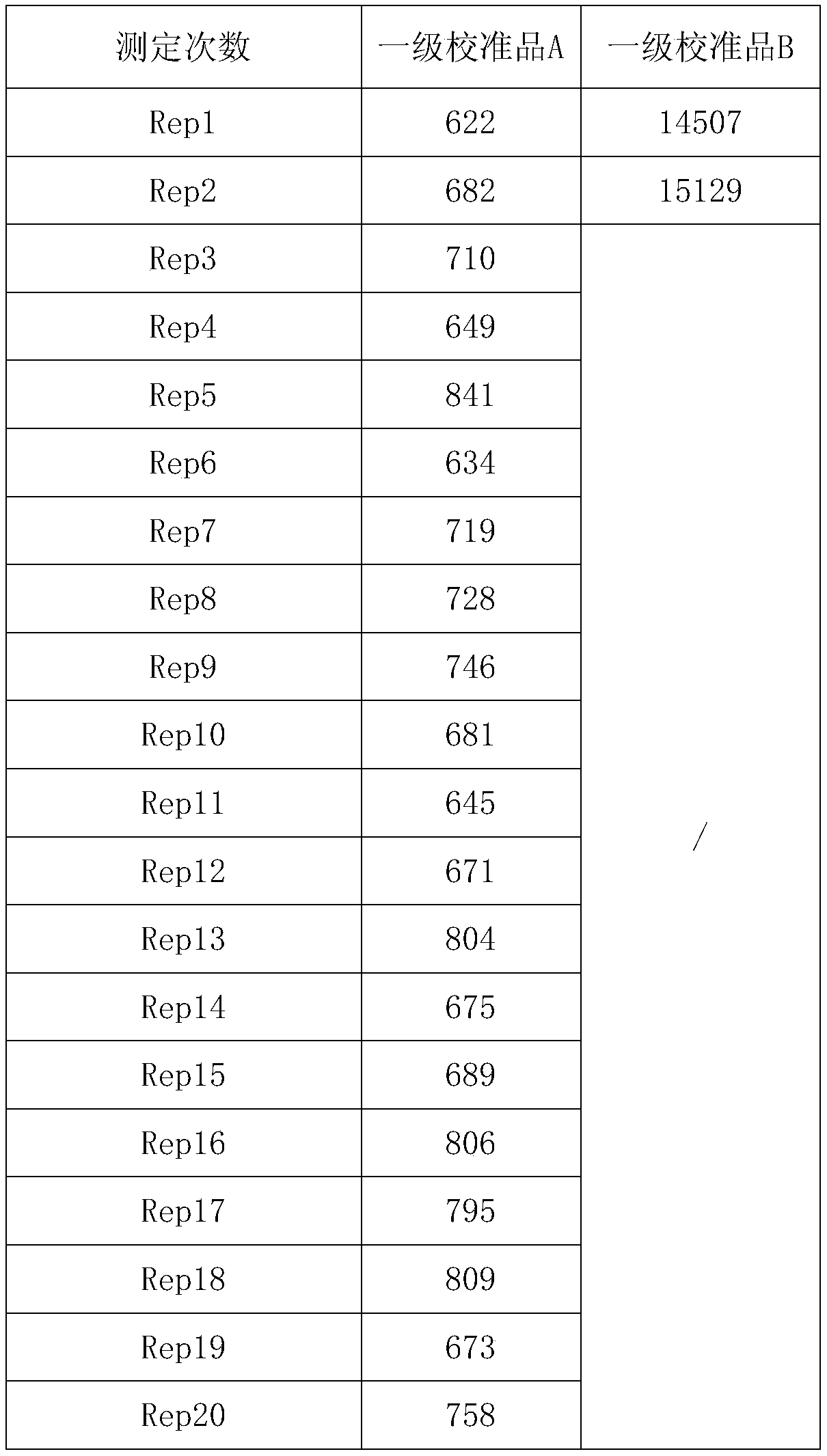

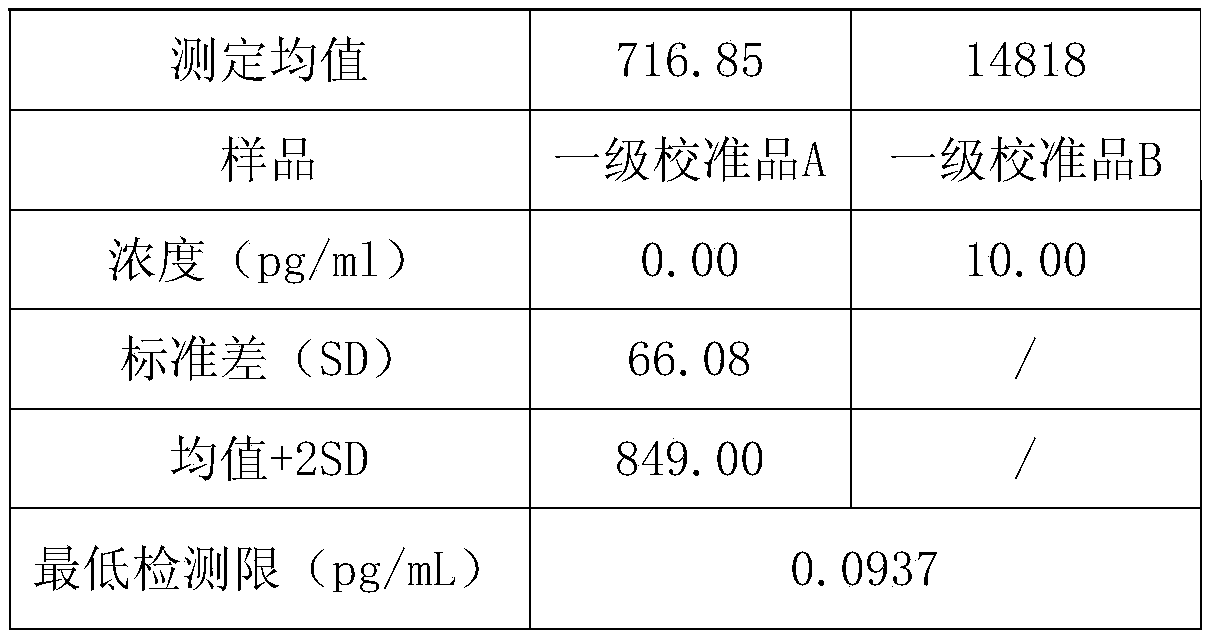

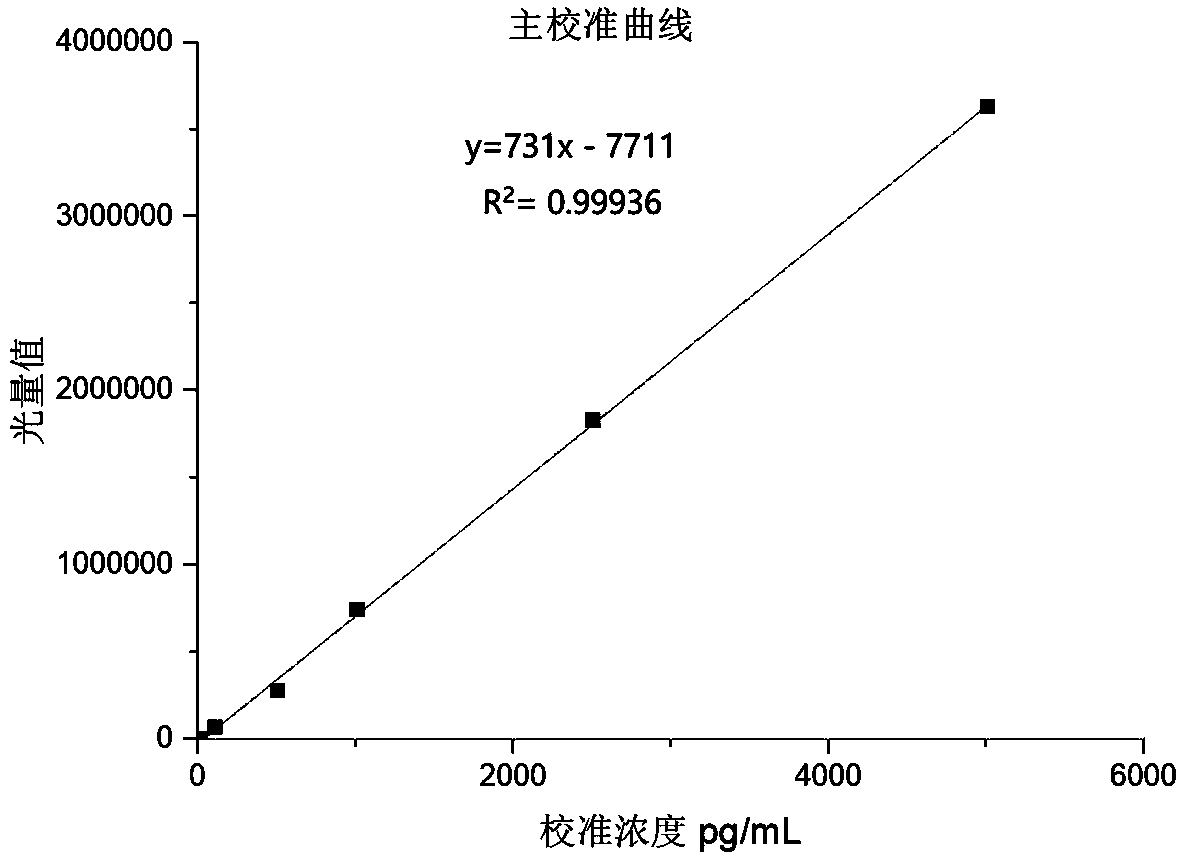

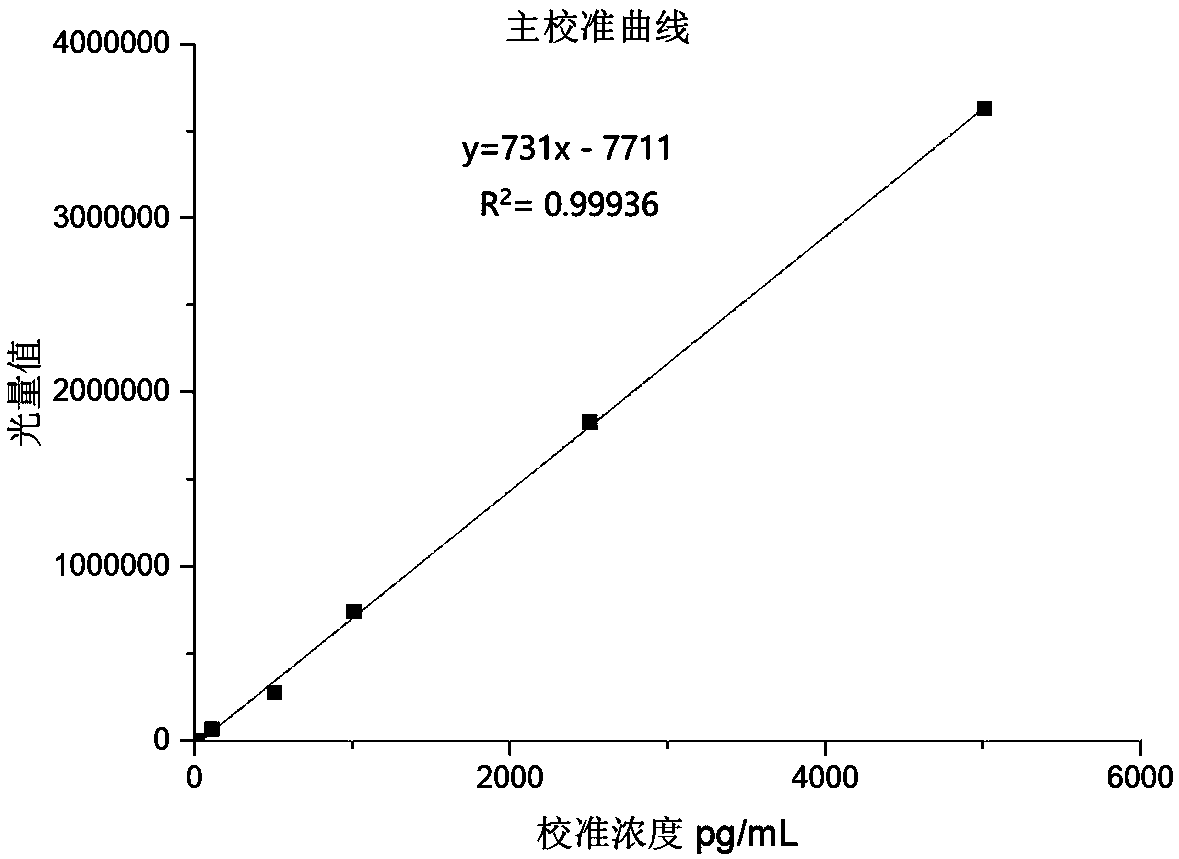

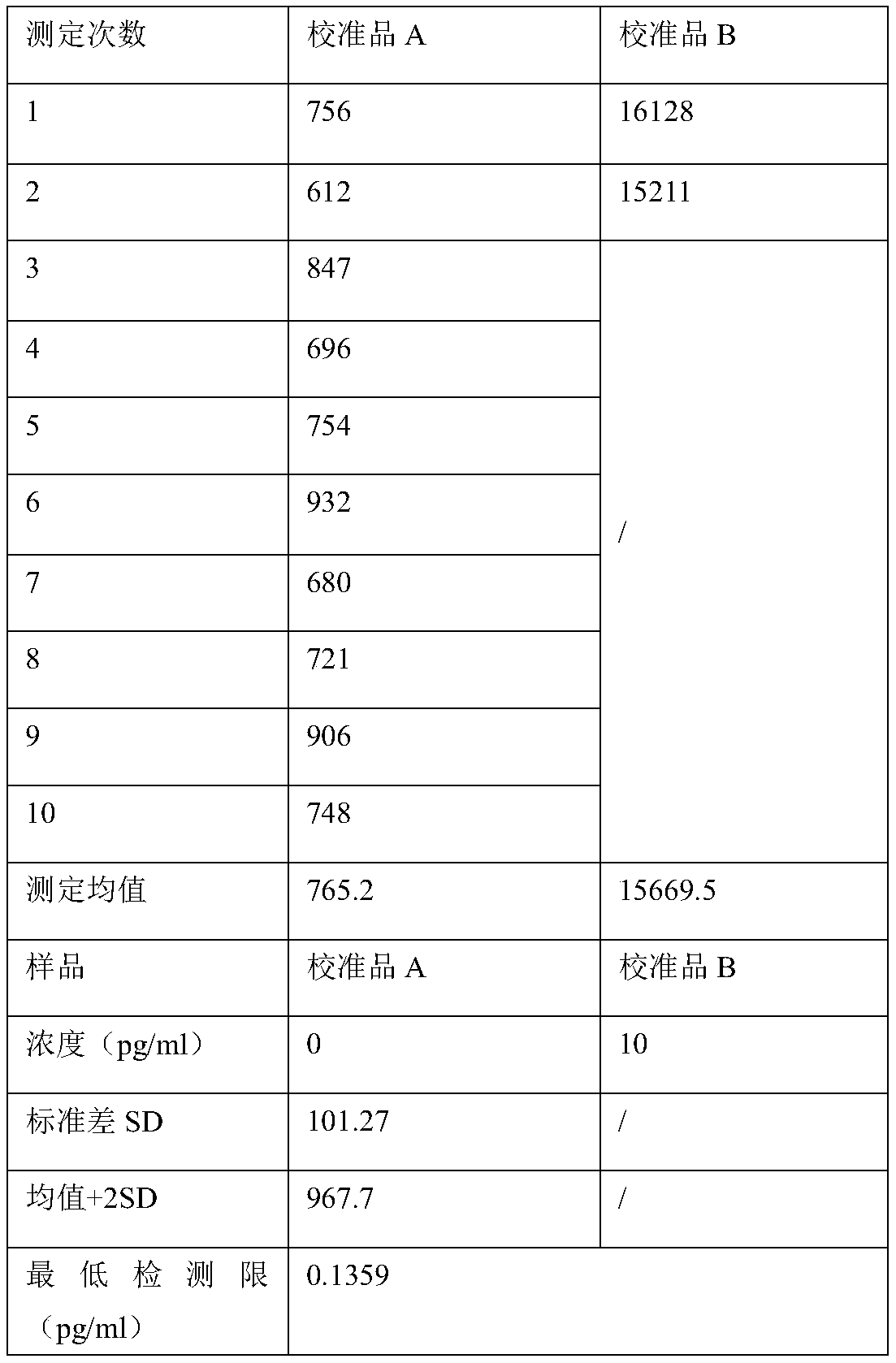

Human Legumain chemiluminiscence detection kit and application thereof

The invention discloses a human Legumain chemiluminiscence detection kit and application thereof. The kit comprises the following components: a) streptavidin magnetic bead suspension; b) a Legumain antibody labeled by acridinium ester; c) a Legumain antibody labeled by using biotin; d) a chemiluminescent substrate solution comprising a solution A and a solution B, the solution A being a nitric acid solution and the solution B being a sodium hydroxide solution; e) calibrators: Legumain antigens with the concentrations of 0 pg / mL, 10 pg / mL, 50 pg / mL, 100 pg / mL, 500 pg / mL, 1000 pg / mL and 2500 pg / mL; f) a quality control product; g) a cleanout fluid. According to the kit, streptavidin magnetic bead suspension liquid serves as a solid-phase carrier for immune reaction and separation, avidin magnetic particles are mainly used for being connected with biotin labeled antibodies, and target substances can be captured by the avidin magnetic particles through the immune reaction to form immune complexes.

Owner:南京拂晓生物科技有限公司

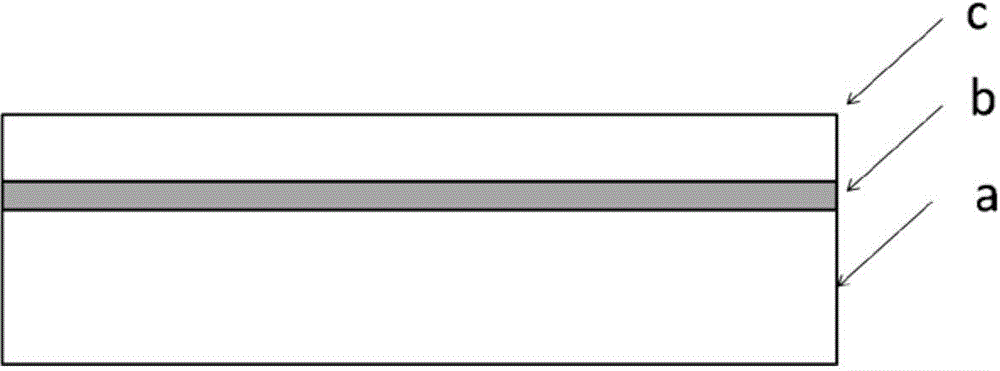

Carbon-nanotube-based transparent antistatic pressure-sensitive adhesive structure and application thereof

InactiveCN104946142AImprove anti-static effectProtection securityFilm/foil adhesivesAdhesiveNanotube

The utility model discloses a transparent anti-electrostatic pressure-sensitive adhesive structure based on carbon nanotubes and an anti-electrostatic protecting membrane. The pressure-sensitive adhesive structure comprises a carbon nanotube transparent conductive network and a pressure-sensitive adhesive layer which is overlapped with the carbon nanotube transparent conductive network. The anti-electrostatic protecting membrane comprises a base material, the carbon nanotube transparent conductive network covering one side of the base material, and the pressure-sensitive adhesive layer covering the carbon nanotube transparent conductive network, has excellent anti-electrostatic property, has electrostatic voltage less than 100V when being rapidly peeled off from a base body such as glass and plastic, and can effectively protect the security and the cleanness of electronic equipment; meanwhile the carbon nanotube transparent conductive network has great porosity, does not affect the combination of the base material with the pressure-sensitive adhesive, is applicable to various normal pressure-sensitive adhesives, is easy to prepare and low in cost, and has a great application market.

Owner:SUZHOU HANANO MATERIALS TECH LTD

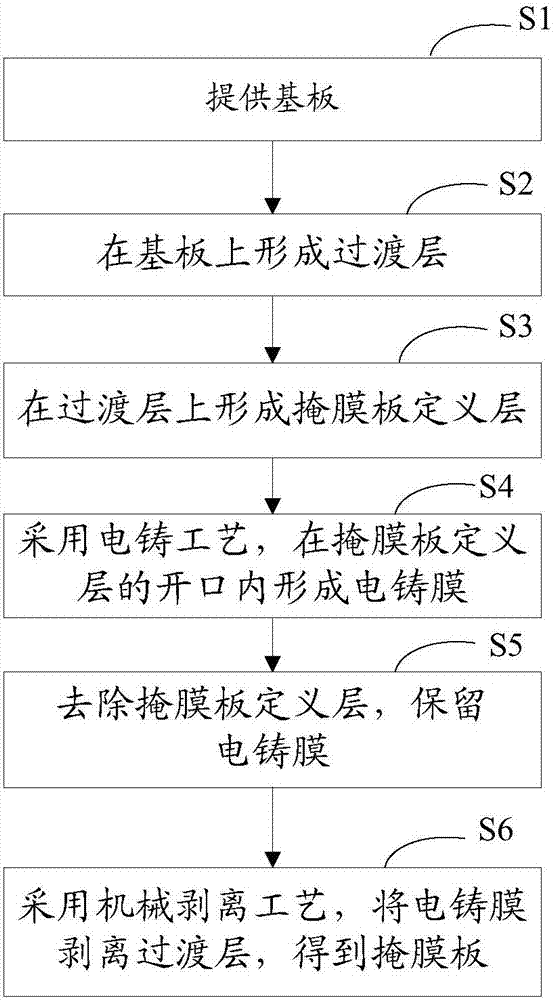

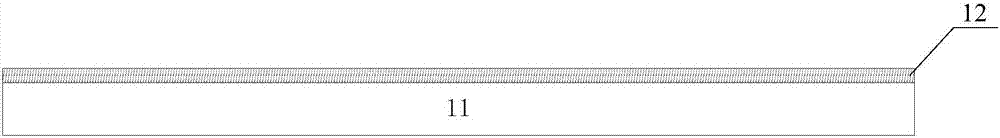

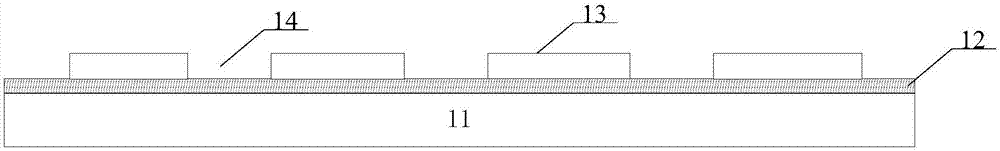

Mask plate and fabrication method thereof

ActiveCN107119288AAvoid damageDoes not affect bindingVacuum evaporation coatingSputtering coatingEngineeringTransition layer

The invention discloses a mask plate fabrication method. The method comprises the steps that a substrate is provided; an electric-conductive transition layer is formed on the substrate; an insulating mask plate definition layer is formed on the transition layer, and the mask plate definition layer is provided with a plurality of openings to expose the transition layer; the mask plate definition layer is served as a mask, the transition layer exposed by the multiple openings in the mask plate definition layer is served as an electrode, an electroforming process is adopted, and electroforming films are formed in the openings of the mask plate definition layer; the mask plate definition layer is removed, and the electroforming films are reserved; a mechanical stripping process is adopted, the electroforming films are stripped from the transition layer, and a mask plate is obtained; and the adhesive force between the electroforming films and the transition layer is smaller than that between the transition layer and the substrate and smaller than that between the electroforming films and the substrate. Compared with the prior art, in the process of stripping the electroforming films from the transition layer, the damage to the electroforming films is reduced, and the yield of the mask plate is increased to a certain degree.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com