Tanning method for double-face leather

A dual-purpose, wool leather technology, applied in the application, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Reduce the softness, reduce the bonding force between the quilt and the skin, and easily cause hair loss, etc., to achieve the effect of improving the plumpness, plumpness of the skin, shrinking temperature and high softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

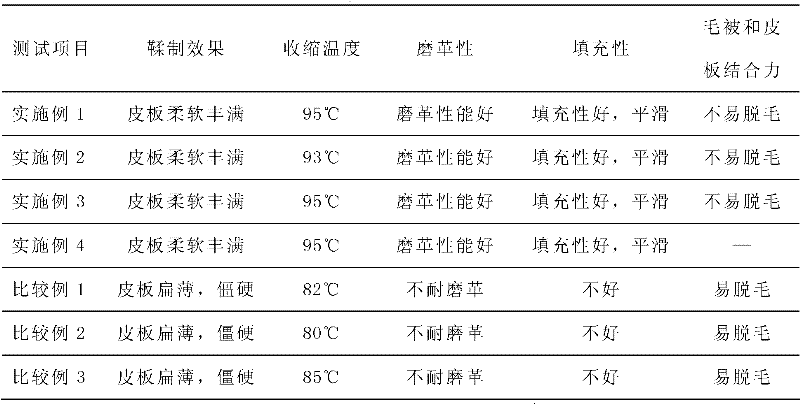

Examples

Embodiment 1

[0045] 1. Pretreatment

[0046] The sheepskin is soaked in water, the soaking solution includes: 1% non-ionic degreasing agent, 1% soaking aid and 3000% water, and the soaking time is 24 hours;

[0047] The sheepskin after soaking in water is softened, and the softening agent includes: 2.1% softening enzyme, 0.3% sodium carbonate and 200% water, and the softening time is 90 minutes;

[0048] The softened sheepskin is subjected to pickling treatment, the pickling solution includes: 3% formic acid, 0.6% sulfuric acid and 1200% water, and the pickling time is 180 minutes.

[0049] 2. Main tanning

[0050] Add 10% sodium chloride, 6% tetrakis hydroxymethyl phosphine sulfate and 0.8% tanning auxiliary to the pickling solution, put the above mixed solution into the drum, put the dual-purpose skin of fur and leather obtained in step 1 into the drum In the drum, set the main tanning temperature to 32°C and rotate for 30 minutes to complete the main tanning.

[0051] 3. Retanning

...

Embodiment 2

[0054] 1. Pretreatment

[0055] The sheepskin is soaked in water, the soaking solution includes: 0.9% non-ionic degreasing agent, 0.9% soaking aid and 2500% water, and the soaking time is 24 hours;

[0056] The sheepskin after soaking in water is softened, and the softening agent includes: 1.5% softening enzyme, 0.2% sodium carbonate and 200% water, and the softening time is 90 minutes;

[0057] The softened sheepskin is subjected to pickling treatment, the pickling solution includes: 2% formic acid, 0.6% sulfuric acid and 1000% water, and the pickling time is 180 minutes.

[0058] 2. Main tanning

[0059] Add 9% sodium bicarbonate, 5% tetrakis hydroxymethyl phosphine chloride and 0.6% tanning auxiliary to the pickling solution, put the above mixed solution into the drum, put the dual-purpose leather obtained in step 1 into In the drum, set the main tanning temperature to 30°C, and rotate for 35 minutes to complete the main tanning.

[0060] 3. Retanning

[0061] Continue ...

Embodiment 3

[0063] 1. Pretreatment

[0064] The sheepskin is soaked in water, the soaking solution includes: 1.2% non-ionic degreasing agent, 1.2% soaking aid and 3500% water, and the soaking time is 24 hours;

[0065] The sheepskin after soaking in water is softened, and the softening agent includes: 2.5% softening enzyme, 0.4% sodium carbonate and 200% water, and the softening time is 90 minutes;

[0066] The softened sheepskin is subjected to pickling treatment, the pickling solution includes: 4% formic acid, 0.8% sulfuric acid and 1200% water, and the pickling time is 180 minutes.

[0067] 2. Main tanning

[0068] Add 13% sodium chloride, 6% tetrakis hydroxymethyl phosphine sulfate and 0.8% tanning auxiliary to the pickling solution, put the above mixed solution into the drum, put the dual-purpose skin of fur and leather obtained in step 1 into the drum In the drum, set the main tanning temperature to 30°C and rotate for 25 minutes to complete the main tanning.

[0069] 3. Retannin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com