Display panel, preparation method and display device

A display panel and sub-panel technology, which is applied to electrical components, electrical solid devices, circuits, etc., can solve problems affecting the normal light emission of micro light-emitting diodes, achieve the effects of saving production costs, simplifying process steps, and improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

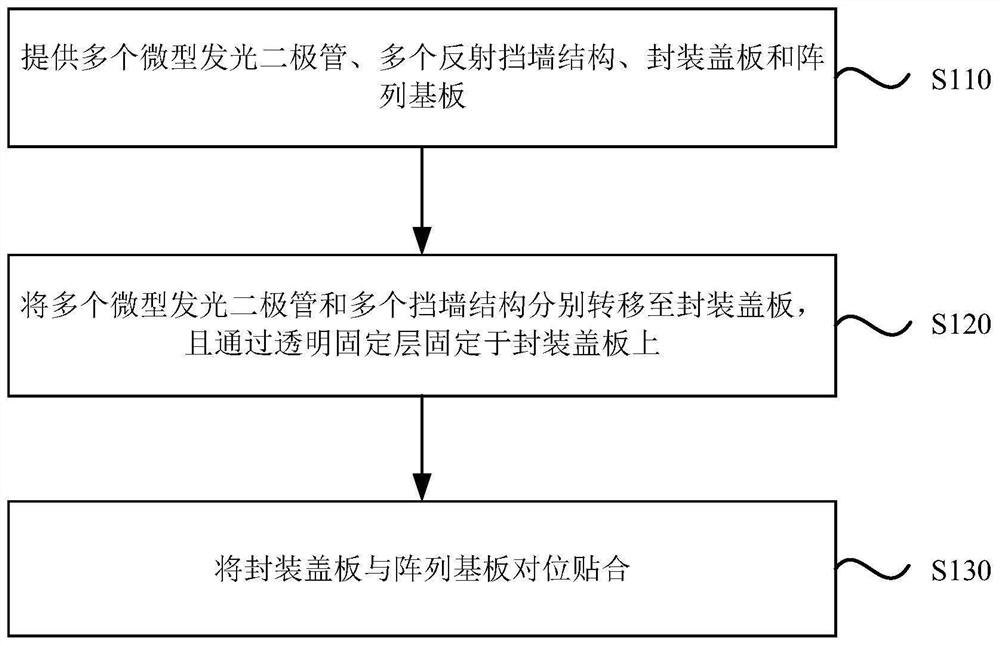

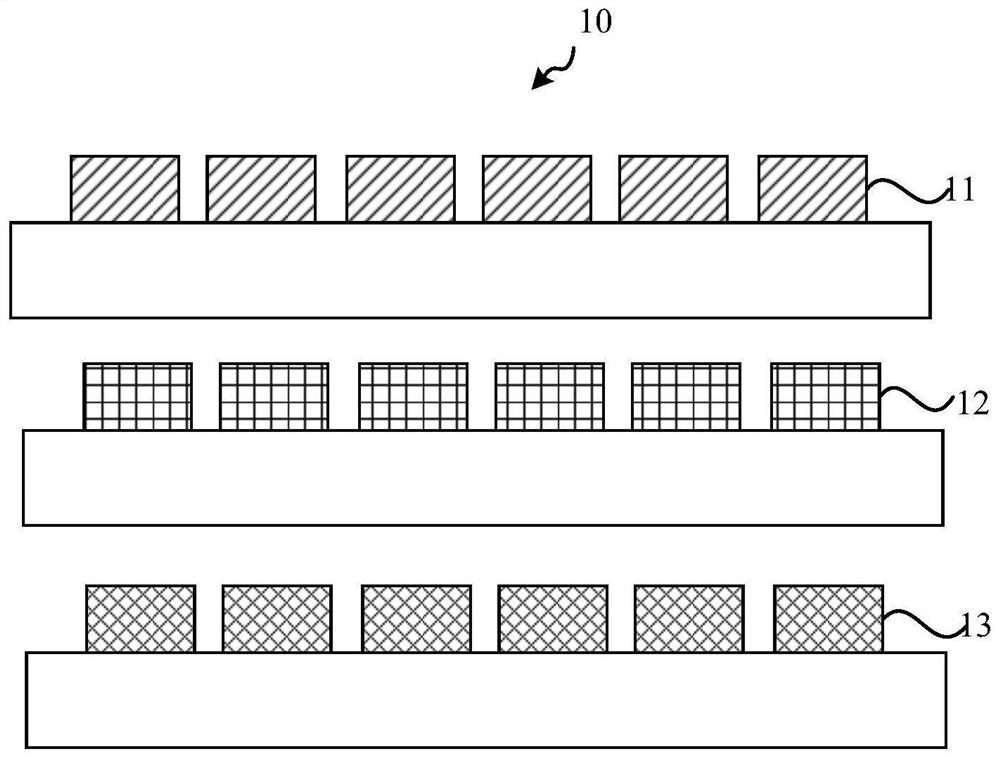

[0051]In view of the problems of the background technology, an embodiment of the present invention provides a method for manufacturing a display panel. The method for manufacturing a display panel includes: providing a plurality of miniature light-emitting diodes, a plurality of reflective wall structures, a packaging cover plate, and an array substrate; The packaging cover plate includes a cover plate and a transparent fixed layer on one side of the cover plate; the array substrate includes a base substrate and a conductive layer on one side of the base substrate; the conductive layer includes a plurality of conductive electrodes; multiple micro light emitting diodes and multiple The reflective wall structures are respectively transferred to the package cover plate, and fixed on the package cover plate through a transparent fixing layer; at least one micro light-emitting diode forms a pixel unit; the reflective wall structure is located between adjacent pixel units; the package...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com