Plugging agent for under-pressure plugging repair and construction method of plugging agent

A technology of plugging leakage under pressure and construction method, applied in the direction of adhesive, adhesive type, adhesive additive, etc., can solve the problem of lack of protective repair measures for pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

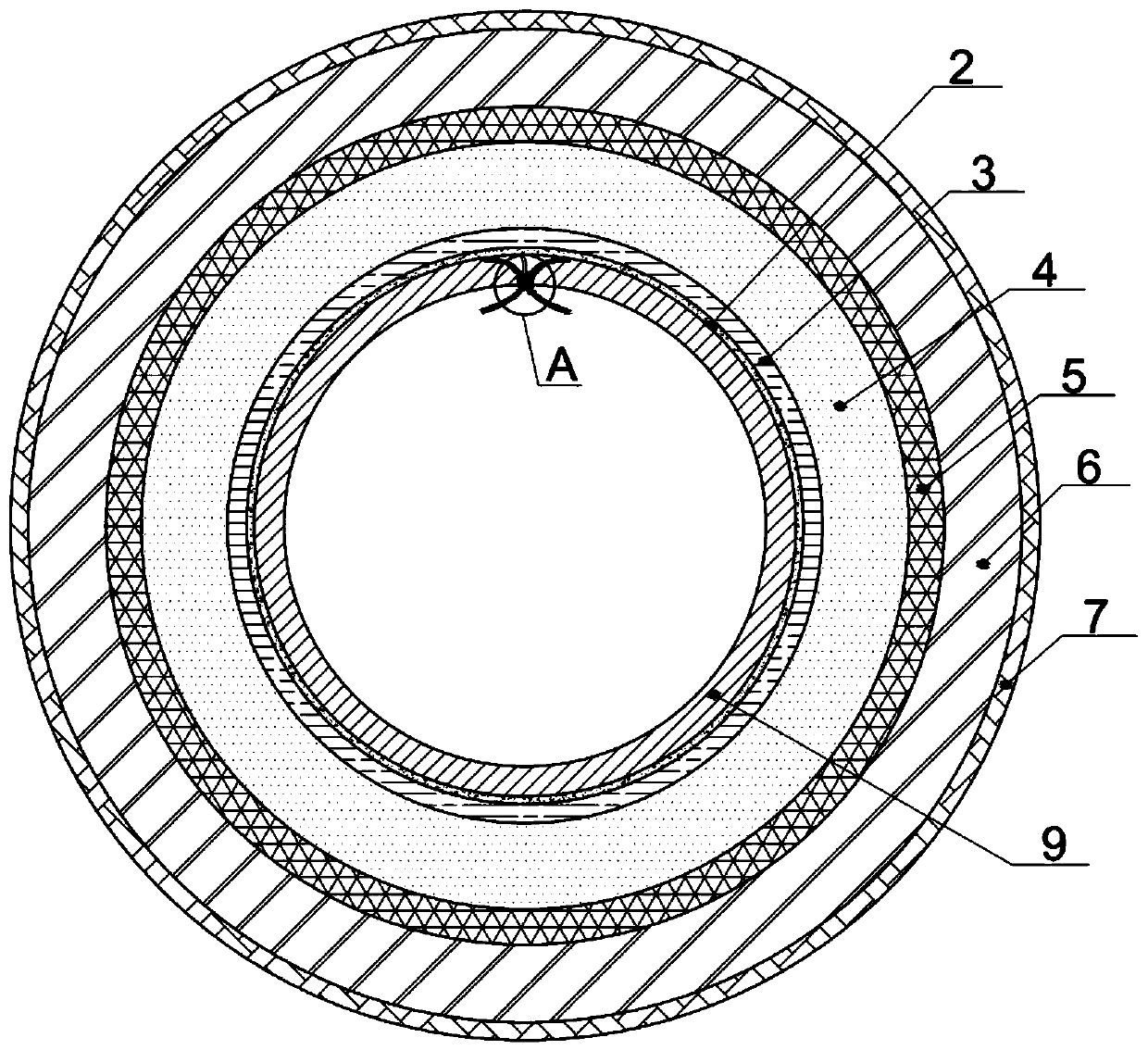

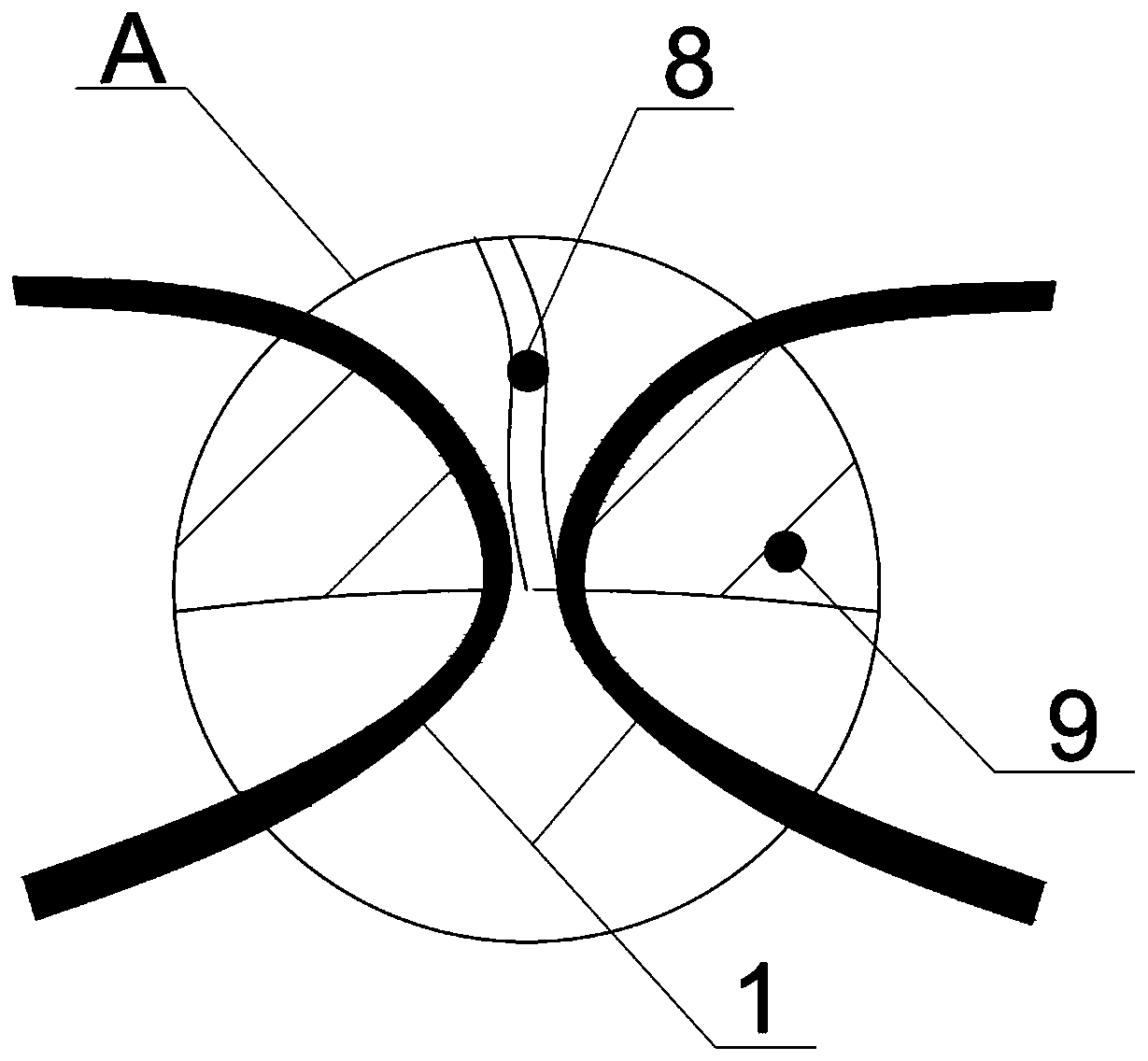

[0029] refer to figure 1 and figure 2 As shown, when a plugging agent for leak plugging repair under pressure provided by Embodiment 1 of the present invention is used for leak plugging of pipelines under pressure, the plugging block 1, reinforcement layer 2, Flame-retardant and anti-corrosion paste layer 3, flame-retardant and anti-corrosion tape layer 4, oily barrier layer 5, anti-corrosion protective cover 6 and anti-sticking, stain-resistant and weather-resistant surface coating 7, wherein the plugging block 1 is damaged through the corrosion perforation on the pipeline 9 Point 8 goes deep into the pipeline. The plugging block 1 includes the inner part of the pipe, the wall part and the outer part of the pipe. The outer part of the pipe is larger than the inner part of the pipe. Under the action of the layer, it is fitted and fixed on the outer wall of the pipeline, the plugging block 1 is embedded in the reinforcement layer, and the reinforcement layer 2 is coated on th...

Embodiment 2

[0055] Based on the same inventive concept, Embodiment 2 of the present invention provides a construction method of a plugging agent for leak plugging and repair under pressure. The construction method uses the above-mentioned plugging agent for leak plugging and repair under pressure. The construction methods mentioned above include:

[0056] (1) Clean the surface of the metal pipe structure in the construction area to remove oil, salt, and water, and polish it to a St2 standard or above until the surface of the metal pipe structure is free of steel thorns, attachments, oxide scales and obvious bubbling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com