Method for electrogalvanizing on surface of magnesium lithium alloy

A magnesium-lithium alloy and electro-galvanizing technology, which is applied in the field of electro-galvanizing and electro-galvanizing on the surface of magnesium-lithium alloys, can solve problems such as strong electronegativity and difficult electroplating, and achieve the effects of improving corrosion resistance, increasing speed, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Example 1: This scheme is the best scheme. The grade of magnesium-lithium alloy used in the experiment is MBLS10A-200, which is cut into 25mm×35mm×2mm thin slices. The following examples are all performed using workpieces of this specification.

[0037] (1) Grinding: use 400-mesh, 800-mesh, and 1500-mesh sandpaper to polish the surface of the magnesium-lithium alloy substrate workpiece until the oil layer and oxide layer are removed;

[0038] (2) Degreasing: In an alkali-resistant tank with a temperature of 60°C, soak the workpiece in lye for 10 minutes to remove the residual oil layer on the surface of the workpiece. The lye includes 60g / L sodium hydroxide and 10g / L sodium phosphate. Rinse with deionized water for 3 times and proceed to the next step;

[0039] (3) Etching: In a corrosion-resistant tank at 15°C, etch the workpiece with mixed acid solution for 15s to remove the oxide layer on the surface of the workpiece. The mixed acid solution includes phosphoric aci...

example 2

[0047] In this example, the steps of activation and galvanizing before the test electroplating were changed, and the concentration and temperature of the reaction were increased to speed up the processing speed. Compared with Example 1, the difference lies in the following steps:

[0048] (1) Activation: In a corrosion-resistant tank at 75°C, soak the workpiece in the activation solution for 1 min. In this example, the activation solution formula is potassium pyrophosphate 110 / L and sodium carbonate 40g / L, and the workpiece is rinsed with deionized water for 3 times before entering the next step;

[0049] (2) Zinc dipping: In a zinc dipping tank at 75°C, immerse the workpiece in a zinc dipping solution for 3 minutes, and deposit a fine layer of zinc on the surface of the workpiece. In this example, the formula of zinc dipping solution is 30g / L of zinc sulfate, 120g / L of sodium pyrophosphate, 4g / L of sodium fluoride and 5g / L of sodium carbonate, and the workpiece is rinsed wit...

example 3

[0053] In this example, the current density of the electroplating treatment is increased to speed up the electroplating treatment speed. Compared with Example 1, the difference lies in the following steps:

[0054] (1) The first pre-galvanizing: In the electroplating tank at 30°C, electroplate the workpiece in the pre-plating solution for 10 minutes, and the current density is 2.0A / dm 2 . Pre-plating solution formula is the same as in Example 1. After the workpiece is rinsed with deionized water for 3 times, it enters the next step;

[0055] (2) The second electrogalvanizing: In the electroplating tank at 30°C, electroplate the workpiece in the electroplating solution for 10 minutes, and the current density is 2.0A / dm 2 . Electroplating solution formula is identical with example 1. After the workpiece is rinsed with deionized water for 3 times, it enters the next step;

[0056] All the other processing steps and implementation method are consistent with example one.

[...

PUM

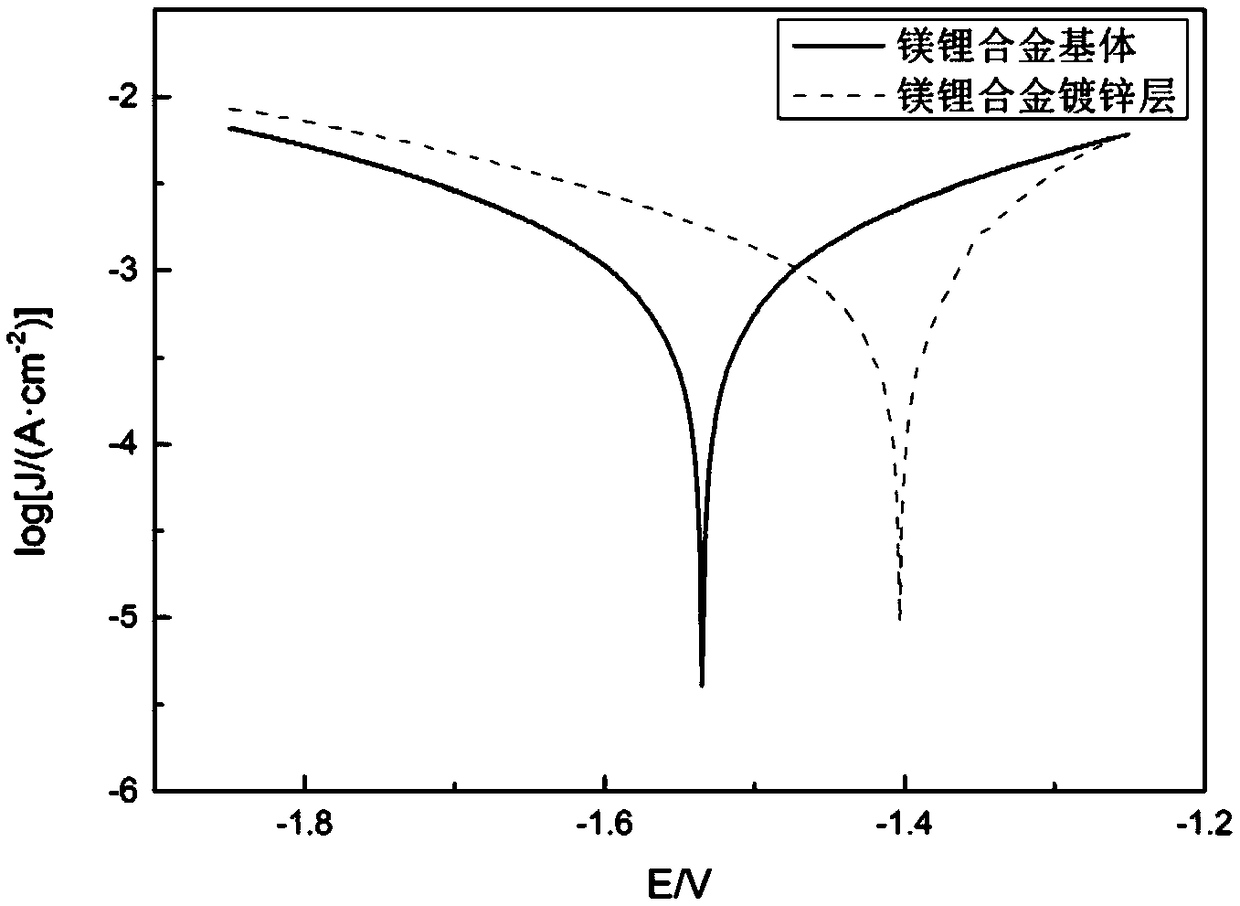

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com