Method for enhancing bonding strength of aluminum coating

A technology combining strength and aluminum coating, which is applied in the field of metal surface treatment, can solve problems such as unsuitability for cold spraying and thermal influence of base metal, and achieve the effects of improved deposition efficiency, increased coating thickness, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

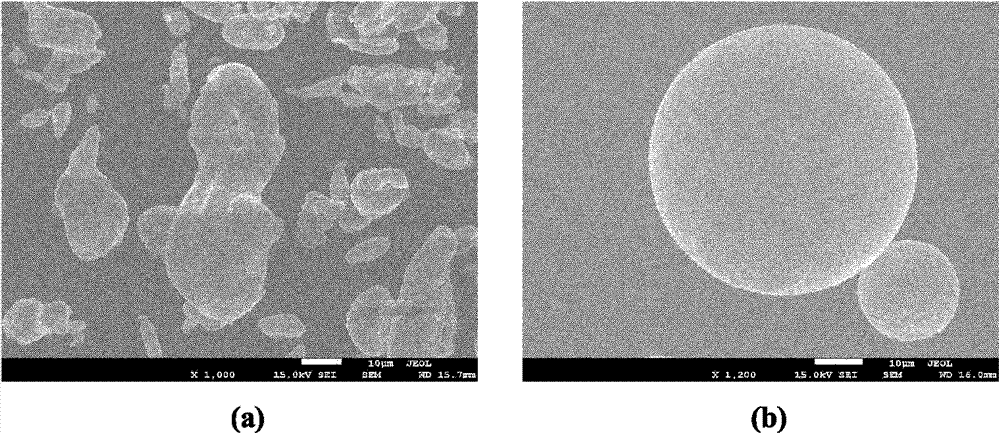

[0026] The selected aluminum powder is high-purity aluminum powder, the purity (mass fraction) is greater than 99%, and the shape is irregular. After sieving, the particles with a particle diameter of less than 45 μm are obtained; the selected aluminum-magnesium intermetallic compound powder is Mg 17 al 12 Spherical powder with an average particle diameter of 58 μm. The original morphology of the two powders is as follows figure 1 shown. The matrix used is Al6061 aluminum alloy in T6 state. High-purity aluminum powder and Mg 17 al 12 The spherical powders are mixed according to the atomic ratio of 75:25, and then mechanically mixed for 10-30 minutes to obtain the mixed powder. The surface of the aluminum substrate was cleaned with acetone, dried, and then cold sprayed with the above-mentioned mixed powder. The working gas and particle carrier gas in cold spraying are both helium, the pressure and temperature of the working gas at the inlet of the spray gun are 0.98MPa an...

Embodiment 2

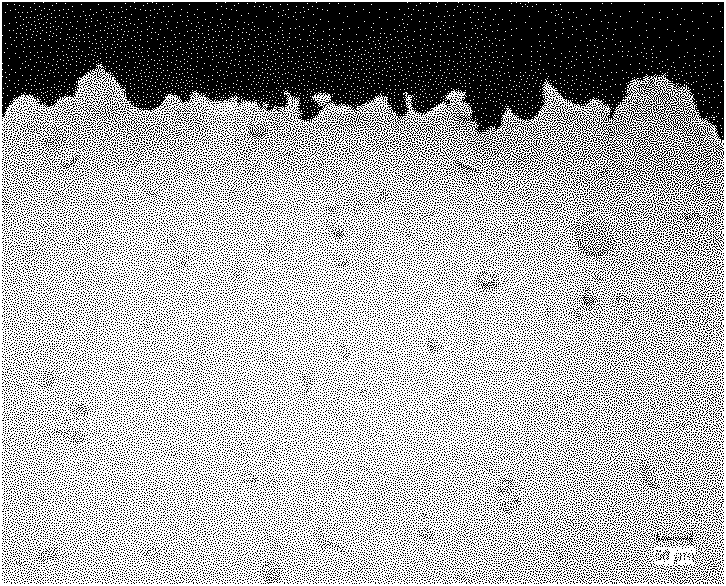

[0028] Select the same aluminum powder, aluminum-magnesium intermetallic compound powder and matrix as in Example 1. High-purity aluminum powder and Mg 17 al 12 The spherical powders are mixed according to the atomic ratio of 50:50, and then mechanically mixed for 10-30 minutes to obtain the mixed powder. The surface of the aluminum substrate was cleaned with acetone and dried. This is followed by cold spraying with the above mixed powder. The working gas and particle carrier gas in cold spraying are both helium, the pressure and temperature of the working gas at the inlet of the spray gun are 0.98MPa and 300°C respectively, the pressure of the carrier gas is 1.04MPa, and the temperature is room temperature. The powder feeding rate is controlled at about 15g / min, the distance from the outlet of the spray gun to the surface of the substrate is 10mm, the moving speed of the substrate relative to the spray gun is 1mm / s, and a single pass is deposited. The resulting coating is...

Embodiment 3

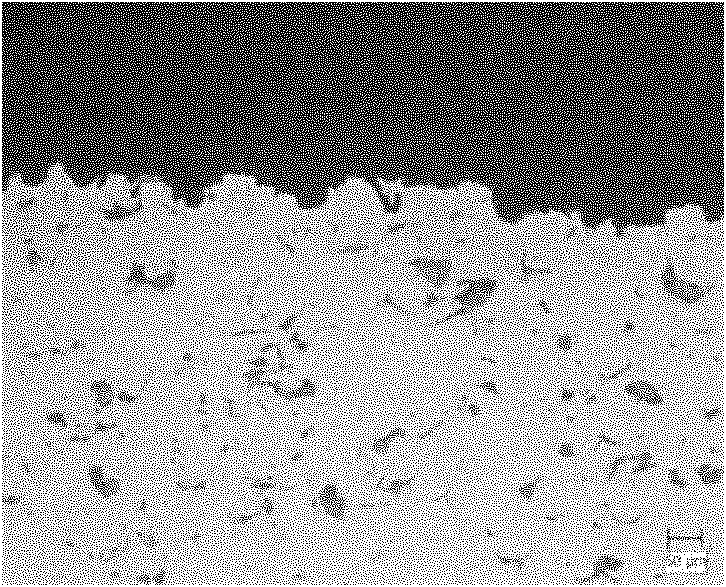

[0030] Select the same aluminum powder and aluminum-magnesium intermetallic compound powder as in Example 1. The matrix used is cast AZ91D magnesium alloy. High-purity aluminum powder and Mg 17 al 12 The spherical powders are mixed according to the atomic ratio of 25:75, and then mechanically mixed for 10-30 minutes to obtain the mixed powder. The surface of the magnesium substrate was cleaned with acetone and dried. This is followed by cold spraying with the above mixed powder. The working gas and particle carrier gas in cold spraying are both helium, the pressure and temperature of the working gas are 0.98MPa and 300°C, the pressure of the carrier gas is 1.04MPa, and the temperature is room temperature. The powder feeding rate is about 15g / min, the distance from the outlet of the spray gun to the surface of the substrate is 10mm, the moving speed of the substrate relative to the spray gun is 2mm / s, and the deposition is performed in two passes. The resulting coating is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com