Antiflaming decoration body paper prepared from antiflaming plant fibers, and preparation method thereof

A technology of plant fiber and decorative base paper, which is applied in fiber raw material treatment, cellulose pulp post-treatment, and cellulose pulp post-treatment modification, etc. Achieving broad market prospects, excellent physical strength, and the effect of improving physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

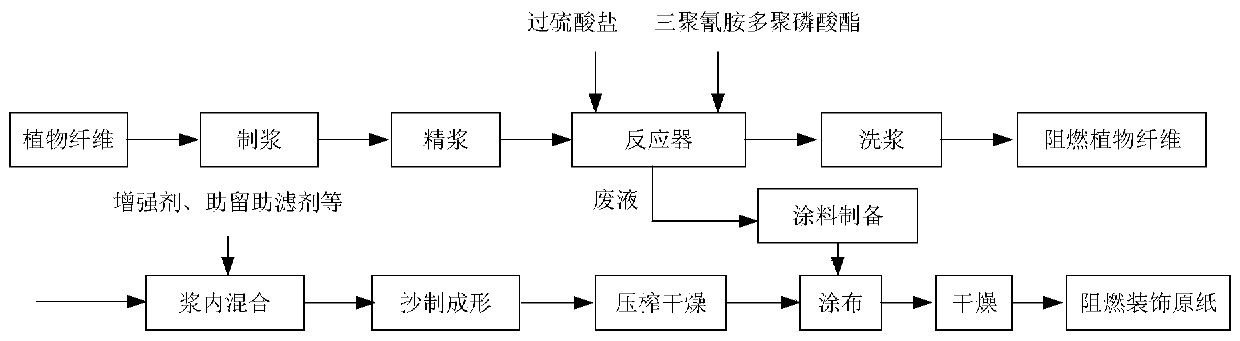

Image

Examples

Embodiment 1

[0038] A method of preparing flame-retardant decorative base paper using flame-retardant plant fibers in this embodiment comprises the following steps:

[0039] (1) Preparation of flame retardant plant fiber

[0040] (11) Mix coniferous wood pulp and hardwood pulp, add them to the hydraulic pulper, control the pulping concentration to 3.0%, pulping time is 20min, and then discharge the material, and then use the softwood pulp and hardwood pulp with a disk 2 trains and 2 sets of mills are mixed in series and parallel to refine pulp to obtain a beating degree of 37°SR and a plant fiber pulp with a concentration of 5wt%, wherein: the mass ratio of softwood pulp and hardwood pulp in the plant fiber pulp is 1: 0.8.

[0041](12) Add the obtained plant fiber pulp and ammonium persulfate into the reactor, heat and stir at a temperature of 85° C. for 1 hour, then add melamine polyphosphate to the reactor, continue stirring and reacting at a constant temperature of 85° C. for 14 hours,...

Embodiment 2

[0050] A method of preparing flame-retardant decorative base paper using flame-retardant plant fibers in this embodiment comprises the following steps:

[0051] (1) Preparation of flame retardant plant fiber

[0052] (11) Mix coniferous wood pulp, broad-leaved wood pulp, and broken paper pulp, and add them to the hydropulper, control the pulping concentration to 2.5%, and the pulping time is 15 minutes, then discharge, and then use soft-leaved wood pulp and hardwood pulp 2 rows and 2 sets of disk refiners for pulp are mixed and refined in series and parallel to obtain plant fiber pulp with a beating degree of 35°SR and a concentration of 4wt%, wherein: softwood pulp, hardwood pulp and broken pulp in the plant fiber pulp The mass ratio of the broken pulp is 1:0.5:0.5, and the concentration of the broke pulp is 3.0wt%.

[0053] (12) Add the obtained plant fiber pulp and sodium persulfate into the reactor, heat and stir at a temperature of 90° C. for 0.5 h, then add melamine pol...

Embodiment 3

[0062] A method of preparing flame-retardant decorative base paper using flame-retardant plant fibers in this embodiment comprises the following steps:

[0063] (1) Preparation of flame retardant plant fiber

[0064] (11) Mix coniferous wood pulp and hardwood pulp, add them to the hydraulic pulper, control the pulping concentration to 3.5%, pulping time is 30min, and then discharge, and then use softwood pulp and hardwood pulp with a disk 2 trains and 2 sets of mills are mixed in series and parallel to refine pulp to obtain plant fiber pulp with a beating degree of 40°SR and a concentration of 5wt%, wherein: the mass ratio of softwood pulp and hardwood pulp in the plant fiber pulp is 1: 0.5.

[0065] (12) Add the obtained plant fiber pulp and potassium persulfate into the reactor, heat and stir at a temperature of 86° C. for 1.5 h, then add melamine polyphosphate to the reactor, and continue to stir and react at a constant temperature of 86° C. for 15 h, Finally, the fiber i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com