High-temperature-resisting anti-corrosive thermal-insulation composite lining structural member and manufacturing method thereof

A composite lining, high temperature resistant technology, applied in the direction of overall lining, etc., can solve the problems of poor anti-corrosion effect, uneven wall erosion, complex thermal power equipment structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

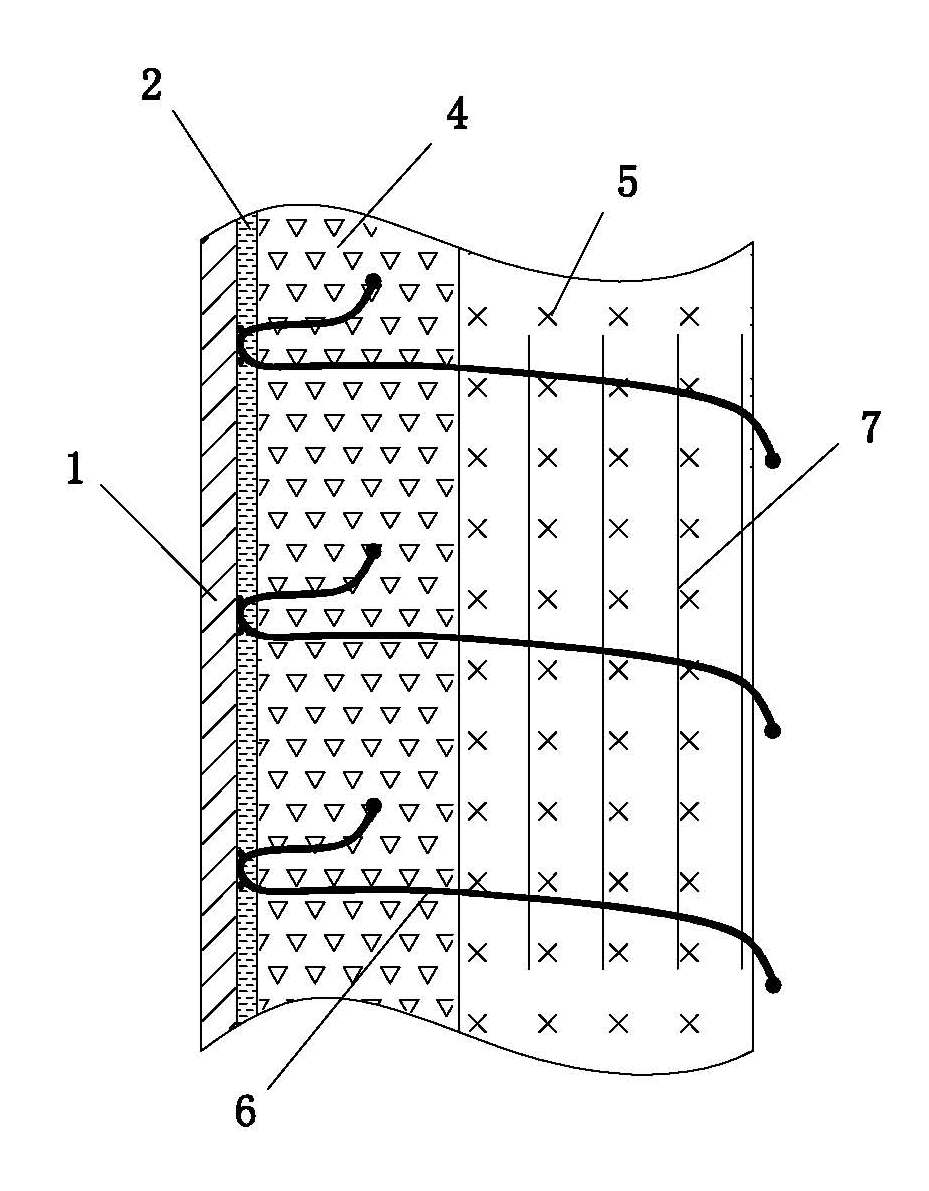

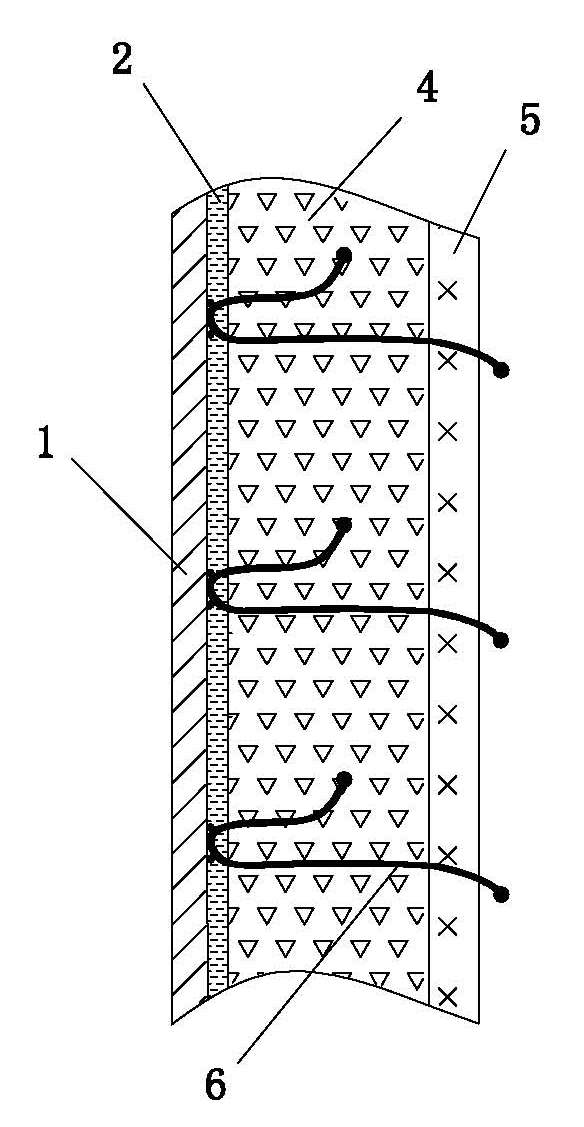

[0030] See figure 1 , The high-temperature-resistant, anti-corrosion, and heat-insulating composite lining structure of this embodiment includes a metal shell 1, anchor nails 6, an anti-dew point corrosion coating layer 2, a lightweight heat-insulating lining material layer 4, and a fiber cotton layer 5.

[0031] The anchor nails 6 are basically U-shaped, and the two claws are set separately, one long and the other short. The head of each anchor nail 6 is welded and fixed on the inner wall of the metal shell 1 . The anchor nails 6 are evenly distributed on the metal shell 1 in the manner of 9-25 per square meter. The anchor nail 6 mainly plays the role of supporting and strengthening the lightweight heat insulation lining material and fiber cotton. The anchor nail 6 is made of high temperature resistant alloy steel.

[0032] The anti-dew point corrosion coating layer 2 is adhesive and plastic, and is bonded to the inner wall of the metal shell 1 and the outside of the head o...

Embodiment 2)

[0046] still see figure 1 , the rest of the present embodiment is the same as the embodiment, the difference is: the thickness of the fiber cotton layer 5 requires 28mm, therefore, the present embodiment does not have the operation of binding the high-temperature-resistant alloy steel wire 7 in step ④ of embodiment 1, and the The spraying only needs to be sprayed once until the thickness reaches the required 28mm.

Embodiment 3)

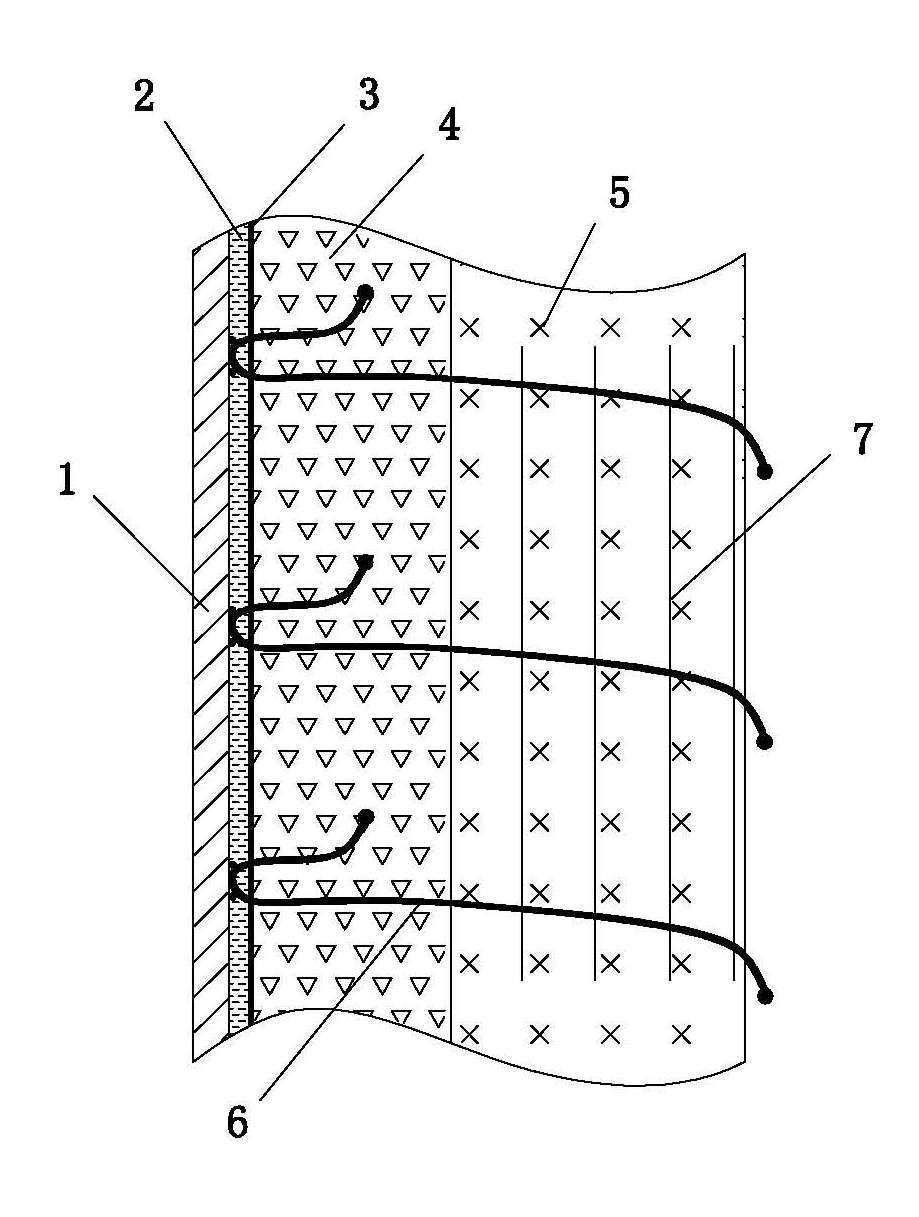

[0048] See figure 2 , the rest of this embodiment is basically the same as that of Embodiment 1, the only difference is that a dew point corrosion-resistant coating layer 2 and a lightweight heat-insulating lining material layer 4 are provided between the high-temperature-resistant anti-corrosion and heat-insulating composite lining structure. The high temperature fiber paper layer 3 has a thickness of 2 mm to 3 mm, and the raw material of the high temperature resistant fiber paper layer 3 is ceramic fiber paper produced by Shandong Luyang Co., Ltd. One side of the high-temperature-resistant fiber paper layer 3 is bonded and fixed to the anti-dew point corrosion coating layer 2, and the other side is bonded and fixed to the lightweight heat-insulating lining material layer 4, and the claws of each anchor nail 6 pass through the high-temperature-resistant fiber paper layer 3.

[0049] Correspondingly, in the method for preparing the above-mentioned high-temperature-resistant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com