Mask plate and fabrication method thereof

A manufacturing method and mask technology, applied in the mask field, can solve the problems of low yield and damage of the mask, and achieve the effect of improving the yield and reducing the damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

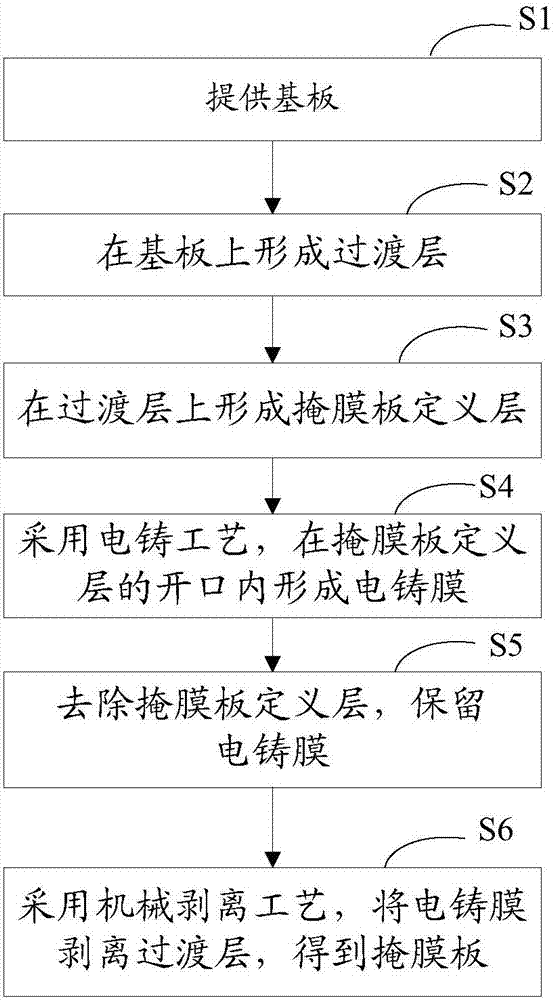

Method used

Image

Examples

Embodiment Construction

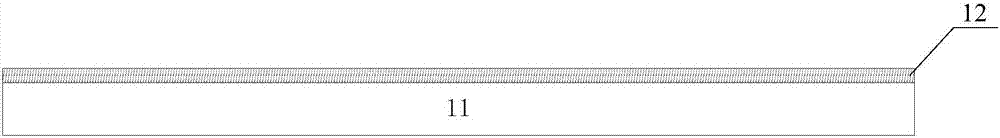

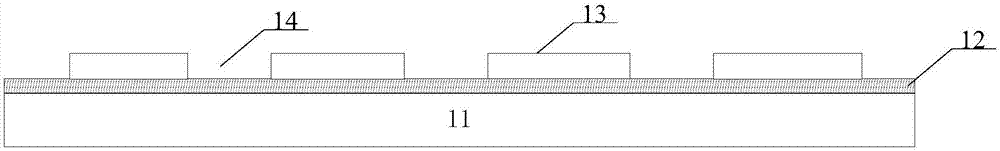

[0035] As described in the background art, the yield rate of the mask plate produced by the method in the prior art is low. The inventors found that the reason for this problem is that the thickness of the high-precision mask plate is very thin, about 5μm-15μm, and there are a large number of openings in the mask, in this case, the electroformed film is directly peeled off from the substrate by using a mechanical stripping process, because there is a certain gap between the electroformed film and the substrate Adhesion, the electroformed film is easily damaged during the process of mechanically peeling off the electroformed film, resulting in a decrease in the yield of the mask.

[0036] Moreover, metal materials such as stainless steel are mostly used as substrates in the prior art, and the materials of electroformed films are mostly metals or alloys. The material properties of the substrate materials and electroformed films are similar, resulting in greater adhesion between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com