Optical glass surface evaporation process

An optical glass and evaporation technology, which is applied in vacuum evaporation coating, metal material coating technology, sputtering coating, etc., can solve the problems of expensive OC0 materials, a large number of personnel and capital costs, and complicated production processes, and reduce the The effect of production cost, reduction of work procedures, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

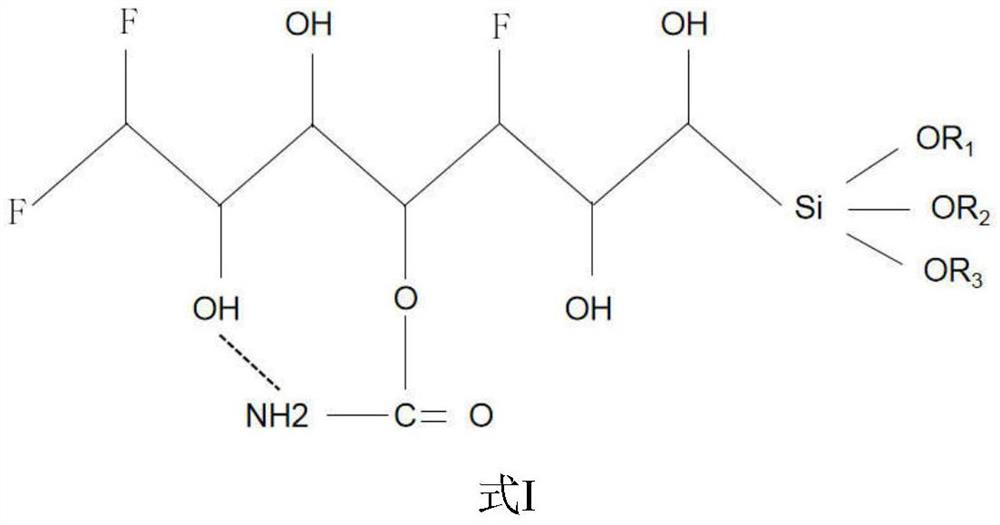

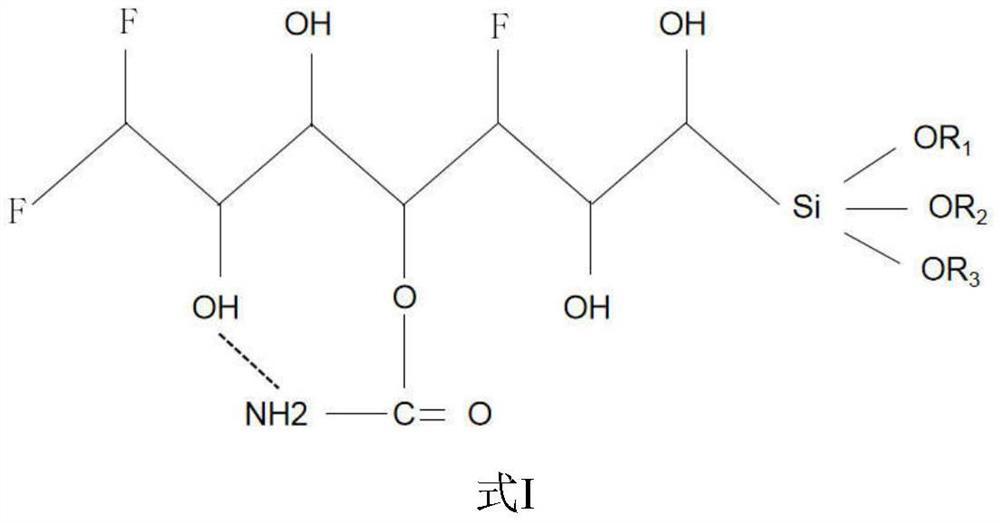

Method used

Image

Examples

Embodiment 1

[0034] After cleaning the surface of the optical glass, conduct plasma treatment on the surface to make the surface water drop angle lower than 15°, then vapor-deposit OC-3001 material on the surface, and then further conduct plasma treatment to continue to vapor-deposit color film or anti-reflection Film, result: water drop angle 20-30°, 100 cells, boiled NG, no follow-up test.

[0035] Result: water drop angle 10-15°, 100 cells, boiled OK, drop ball test trimming;

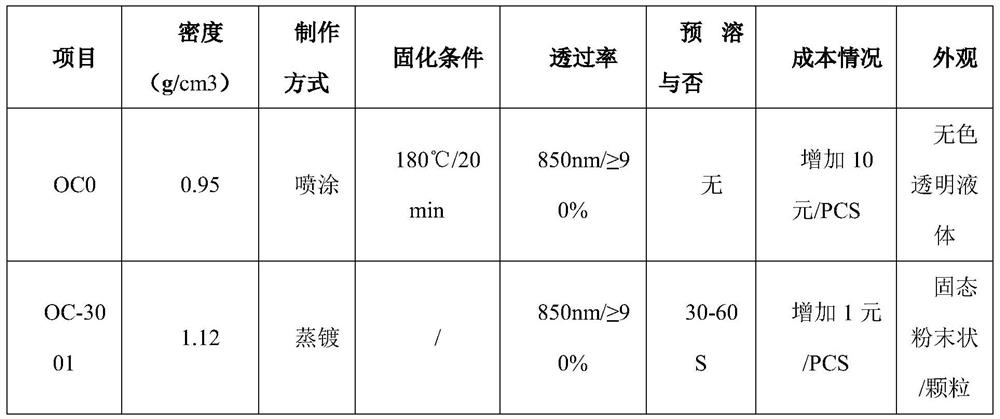

[0036] By comparing the situation and effect of using OC0 and OC-3001 materials, the results described in Table 1 are obtained:

[0037]

[0038] Table 1

[0039] It can be seen from Table 1 that using the combination of the process and materials of the present invention can not only reduce the cost to a great extent, but also can obtain better effects, the process is simpler, and the yield of the obtained product is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com