Method for grinding silicon chips

A grinding method and technology of silicon wafers, applied in the direction of grinding tools, etc., can solve problems such as low product yield, high grinding cost, and defects, and achieve the effect of high product yield and reduced grinding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

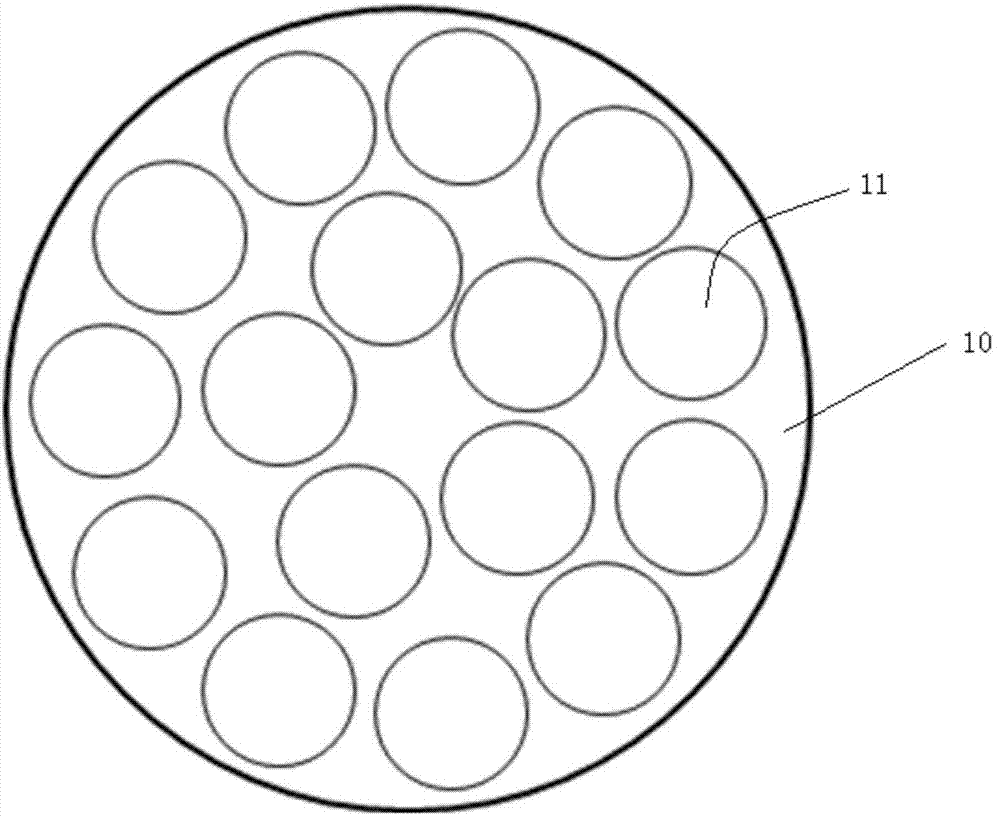

[0014] Silicon wafer grinding methods, such as figure 1 As shown, the silicon wafer is 4 inches, and a 4-inch 16-hole planetary wafer is used to grind the silicon wafer. Sixteen accommodating holes 11 are provided on the planetary plate 1 . The silicon wafer is placed in the holding hole 11 for grinding. Grinding with PWA9 grinding mortar liquid; Grinding separately under multi-stage pressure, the first stage pressure is 270kg, the speed is 5, the speed ratio is 0.5, and the grinding time is 45 seconds; the second stage pressure is 150kg, the speed is 15, and the speed ratio is 0.5. The grinding time is 90 seconds; the pressure of the third stage is 115kg, the speed is 25, the speed ratio is 0.5, and the grinding time is 90 seconds; the pressure of the fourth stage is 100kg, the speed is 30, the speed ratio is 0.5, and the grinding time is 46 seconds; the pressure of the fifth stage is 70kg, speed 35, speed ratio 0.5, grinding time 10 minutes; the interval between pressure c...

Embodiment 2

[0016] Silicon wafer grinding method, the silicon wafer is 4 inches, and a 4-inch 16-hole planetary plate is used to grind the silicon wafer. like figure 1 As shown, the silicon wafer is 4 inches, and a 4-inch 16-hole planetary wafer is used to grind the silicon wafer. Sixteen accommodating holes 11 are provided on the planetary plate 1 . The silicon wafer is placed in the holding hole 11 for grinding. Grinding with PWA9 grinding mortar liquid; Grinding separately under multi-stage pressure, the first stage pressure is 269kg, the speed is 6, the speed ratio is 0.5, and the grinding time is 45 seconds; the second stage pressure is 150kg, the speed is 15, and the speed ratio is 0.4. The grinding time is 90 seconds; the third stage pressure is 123kg, the speed is 24, the speed ratio is 0.6, and the grinding time is 100 seconds; the fourth stage pressure is 95kg, the speed is 35, the speed ratio is 0.5, and the grinding time is 45 seconds; the fifth stage pressure is 75kg, spee...

Embodiment 3

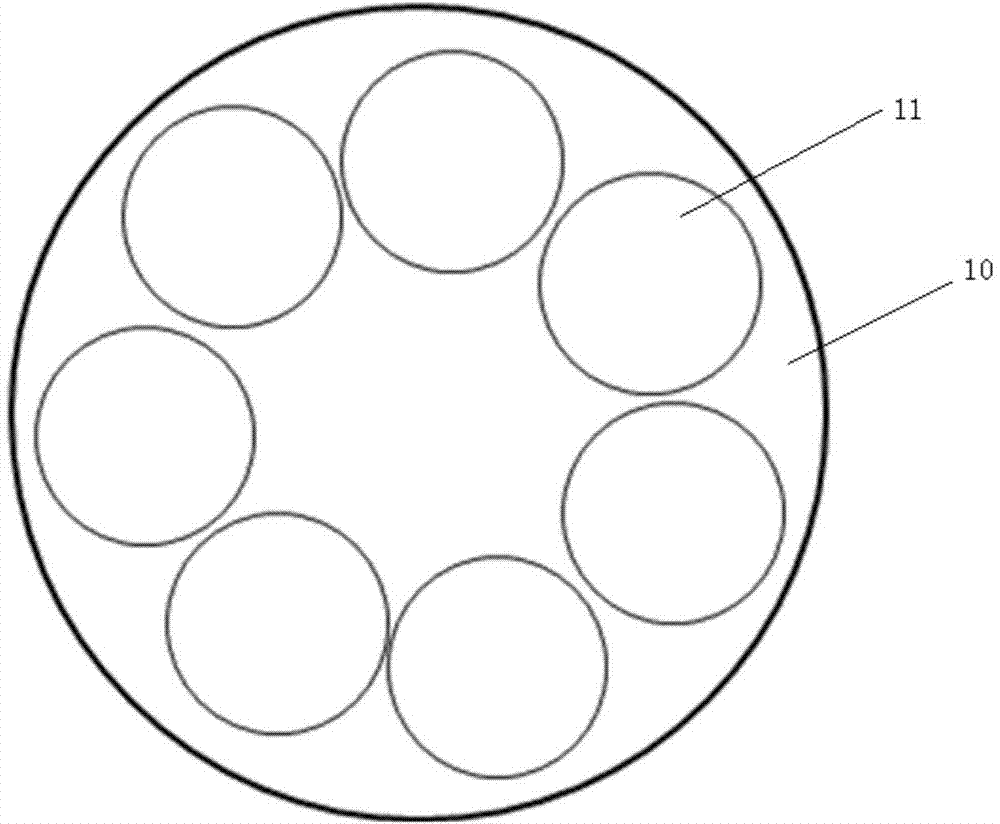

[0018] Silicon wafer grinding methods, such as figure 2 As shown, the silicon wafer is 6 inches, and a 6-inch 7-hole planetary wafer is used to grind the silicon wafer. Seven accommodating holes 11 are arranged on the planet plate 1 . The silicon wafer is placed in the holding hole 11 for grinding. Grinding with PWA9 grinding mortar liquid; Grinding separately under multi-stage pressure, the first stage pressure is 269kg, the speed is 4, the speed ratio is 0.4, and the grinding time is 40 seconds; the second stage pressure is 146kg, the speed is 14, and the speed ratio is 0.5. The grinding time is 80 seconds; the pressure of the third stage is 125kg, the speed is 24, the speed ratio is 0.6, and the grinding time is 100 seconds; the pressure of the fourth stage is 110kg, the speed is 28, the speed ratio is 0.4, and the grinding time is 42 seconds; the pressure of the fifth stage is 80kg, speed of 34, speed ratio of 0.5, grinding time of 9 minutes; the interval between pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com