Low-temperature curved high-strength plastic package glue and preparation method thereof

A high-strength, plastic-encapsulating adhesive technology, applied in adhesives, epoxy resin adhesives, electrical solid devices, etc., can solve the problems of unstable storage, insufficient glue strength, and generation of colloidal volatiles, and achieve a simple and environmentally friendly preparation method and good storage. Stability, improve the effect of explosion-proof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

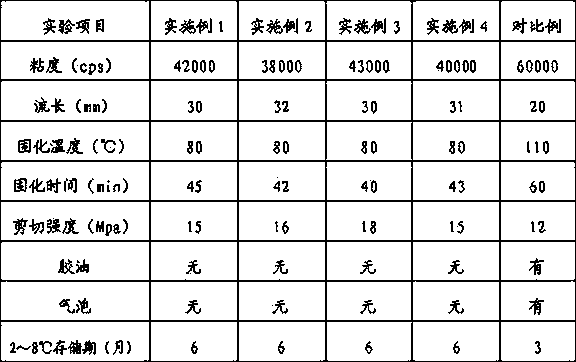

Examples

Embodiment 1

[0028] A low-temperature curing high-strength plastic sealant of the present invention comprises the following components in parts by weight:

[0029] Bisphenol A type epoxy resin (NPEL-128E) 20 parts

[0030] Bisphenol F epoxy resin (NPEL-170) 36 parts

[0031] Nanoscale carbon black 0.2 parts

[0032] Latent hardener (FRX-1020) 15 parts

[0033] Defoamer (BYK-A555) 0.8 parts

[0034] Silica powder 10 parts

[0035] Talcum powder 8 parts

[0036] 8 parts zirconium silicate

[0037] Bisphenol A epoxy resin (NPEL-128E) has a viscosity of 12000-15000 cps and an epoxy equivalent of 184-190. Bisphenol F epoxy resin (NPEL-170) has a viscosity of 2000-5000 cps and an epoxy equivalent of 160-180. The defoamer (BYK-A555) is a silicone-free foam-breaking polymer solution. The particle size of talcum powder is 2500 mesh. The particle size of the zirconium silicate is 4 μm. The particle size of silica powder is 2500 mesh.

[0038] Bisphenol A epoxy resin (NPEL-128E) and bisphe...

Embodiment 2

[0044] A low-temperature curing high-strength plastic sealant of the present invention comprises the following components in parts by weight:

[0045] Bisphenol A type epoxy resin (NPEL-128E) 16 parts

[0046] Bisphenol F epoxy resin (NPEL-170) 42 parts

[0047] Nanoscale carbon black 0.5 parts

[0048] Latent hardener (FRX-1020) 30 parts

[0049] Defoamer (BYK-A555) 1 part

[0050] Silica powder 15 parts

[0051] Talc powder 5 parts

[0052] Zirconium silicate 10 parts

[0053] Bisphenol A epoxy resin (NPEL-128E) has a viscosity of 12000-15000 cps and an epoxy equivalent of 184-190. Bisphenol F epoxy resin (NPEL-170) has a viscosity of 2000-5000 cps and an epoxy equivalent of 160-180. The defoamer (BYK-A555) is a silicone-free foam-breaking polymer solution. The particle size of talcum powder is 2000 mesh. The particle size of the zirconium silicate is 3 μm. The particle size of silica powder is 2000 mesh.

[0054] The suppliers of the above-mentioned components ar...

Embodiment 3

[0060] A low-temperature curing high-strength plastic sealant of the present invention comprises the following components in parts by weight:

[0061] Bisphenol A type epoxy resin (NPEL-128E) 22 parts

[0062] Bisphenol F type epoxy resin (NPEL-170) 40 parts

[0063] Nano-scale carbon black 1 part

[0064] 2-heptadecyl imidazole 10 parts

[0065] Defoamer (BYK-A555) 0.1 parts

[0066] Silica powder 12 parts

[0067] Talc powder 10 parts

[0068] Zirconium silicate 5 parts

[0069] Bisphenol A epoxy resin (NPEL-128E) has a viscosity of 12000-15000 cps and an epoxy equivalent of 184-190. Bisphenol F epoxy resin (NPEL-170) has a viscosity of 2000-5000 cps and an epoxy equivalent of 160-180. The defoamer (BYK-A555) is a silicone-free foam-breaking polymer solution. The particle size of talcum powder is 3000 mesh. The particle size of the zirconium silicate is 5 μm. The particle size of silica powder is 3000 mesh.

[0070] The suppliers of the above-mentioned components ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com