Large-water-absorption-rate aggregate surface treatment agent

A technology of surface treatment agent and water absorption rate, which is applied in the field of high-performance concrete, and can solve the problems of reduced bonding force of cement paste and reduced water absorption rate of aggregates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

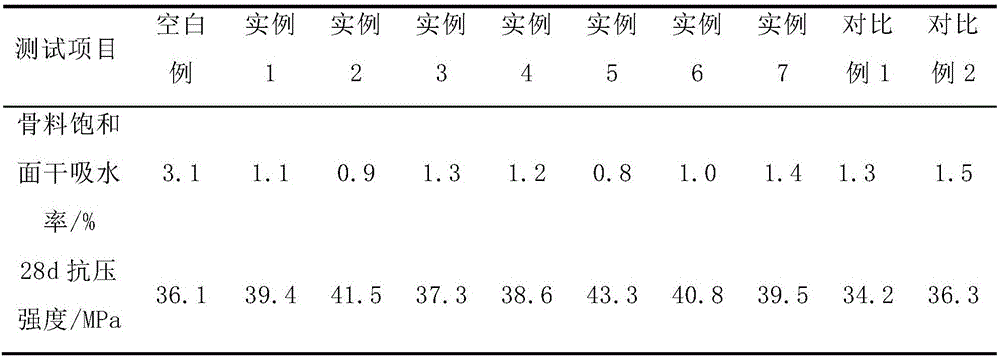

Examples

Embodiment 1

[0043] Mix 20g of silica fume, 20g of limestone powder, 20g of superfine fly ash, 15g of silane, 15g of polyvinyl alcohol, 5g of waterproof alloy powder, and 2g of polycarboxylate superplasticizer to make a large water absorption Aggregate surface treatment agent, add 100g of water to make a treatment agent slurry, soak 1000g of high water absorption aggregate, take out the soaked aggregate, dry it naturally, test its saturated surface dry water absorption, record it as L 1 .

Embodiment 2

[0045] Mix 10g of silica fume, 30g of limestone powder, 30g of superfine fly ash, 10g of silane, 10g of polyvinyl alcohol, 5g of waterproof alloy powder, and 5g of polycarboxylate superplasticizer to make a large water absorption rate Aggregate surface treatment agent, add 100g of water to make a treatment agent slurry, soak 1000g of high water absorption aggregate, take out the soaked aggregate, dry it naturally, test its saturated surface dry water absorption, record it as L 2 .

Embodiment 3

[0047]Mix 29g of silica fume, 10g of limestone powder, 10g of superfine fly ash, 10g of silane, 20g of polyvinyl alcohol, 10g of waterproof alloy powder, and 1g of polycarboxylate superplasticizer to make a large water absorption Aggregate surface treatment agent, add 100g of water to make a treatment agent slurry, soak 1000g of aggregate with high water absorption rate, take out the soaked aggregate and dry it naturally, test its saturated surface dry water absorption rate, record it as L 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com