Ultraviolet light-emitting diode promoting growth of plants

A technology that promotes plant growth and light-emitting diodes, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as unfavorable plant growth, achieve the effects of improving luminous efficiency, reducing damage, and enhancing luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

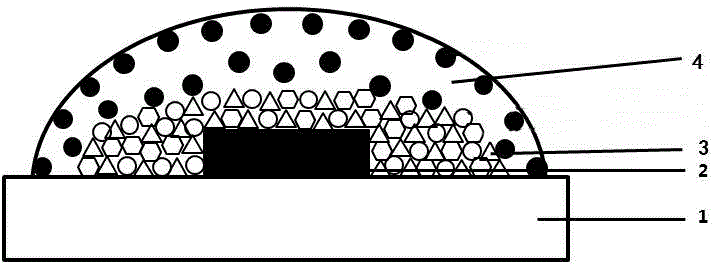

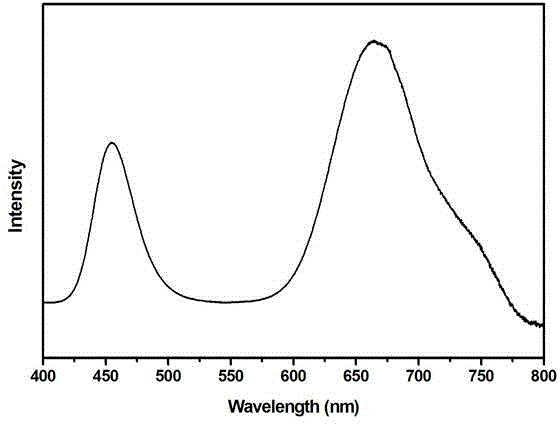

[0033] Such as figure 2 , 3 The schematic diagram of the use of the phosphor powder shown in the figure uses the ultraviolet light-emitting diode chip 2 as the excitation light source, and the luminescent layer 3 on the ultraviolet light-emitting diode chip is doped with chlorophosphate blue phosphor [Ca 5 (PO 4 ) 3 Cl / Eu], nitride red phosphor [Sr 2 Si 5 N 8 / Eu], the molar ratio of the blue phosphor to the red phosphor is 1.5:1, the high-purity inorganic nano-luminescent material adopts zinc oxide nanoflowers, and the total molar ratio of the light-emitting layer 3 on the ultraviolet light-emitting diode chip The ratio is 1:10. The inorganic nanopowder is made of zinc oxide nanoparticles with a particle size of 150 nm, and its mass ratio in the encapsulation layer 4 is 10%.

Embodiment 2

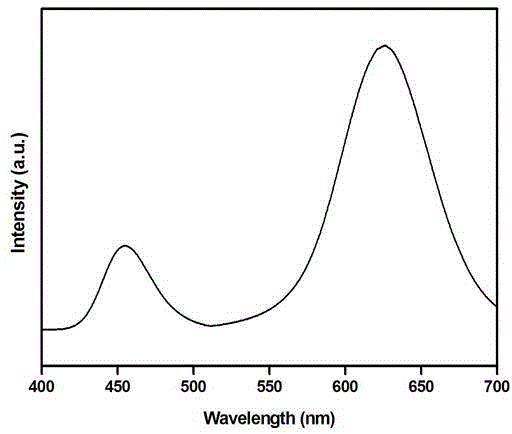

[0035] Such as figure 2 , 3 The schematic diagram of the use of the phosphor powder shown in the figure uses the ultraviolet light-emitting diode chip 2 as the excitation light source, and the luminescent layer 3 on the ultraviolet light-emitting diode chip is doped with chlorophosphate blue phosphor [Ca 5 (PO 4 ) 3 Cl / Eu], nitride red phosphor [CaAlSiN 3 / Eu], the molar ratio of the blue phosphor to the red phosphor is 1.8:1, the high-purity inorganic nano-luminescent material adopts zinc oxide nanoflowers, and the total molar ratio of the light-emitting layer 3 on the ultraviolet light-emitting diode chip The ratio is 1:10. The inorganic nanopowder is made of zinc oxide nanoparticles with a particle size of 150 nm, and its mass ratio in the encapsulation layer 4 is 10%.

Embodiment 3

[0037] Such as figure 2 , 3The schematic diagram of the use of the phosphor powder shown in the figure uses an ultraviolet light-emitting diode chip 2 as an excitation light source, and the luminescent layer 3 on the ultraviolet light-emitting diode chip is doped with chlorophosphate blue phosphor [Ba 5 (PO 4 ) 3 Cl / Eu], nitride red phosphor [SrAlSiN 3 / Eu], the molar ratio of the blue phosphor to the red phosphor is 2.1:1, the high-purity inorganic nano-luminescent material adopts zinc oxide nanoflowers, and the total molar ratio of the light-emitting layer 3 on the ultraviolet light-emitting diode chip The ratio is 1:10. The inorganic nanopowder is made of zinc oxide nanoparticles with a particle size of 150 nm, and its mass ratio in the encapsulation layer 4 is 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com