Repair method for steel storage tank corrosion pit

A technology for pits and storage tanks, which is applied in metal material coating process, coating, melting spray plating, etc., can solve the problems of reducing the adhesion force of carbon fiber cloth and unable to play a role in reinforcement, so as to reduce the difficulty of repairing, Improve corrosion resistance, service life and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The repair and reinforcement process of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, and are only examples. Meanwhile, by way of explanation, the advantages of the present invention will become clearer and easier to understand.

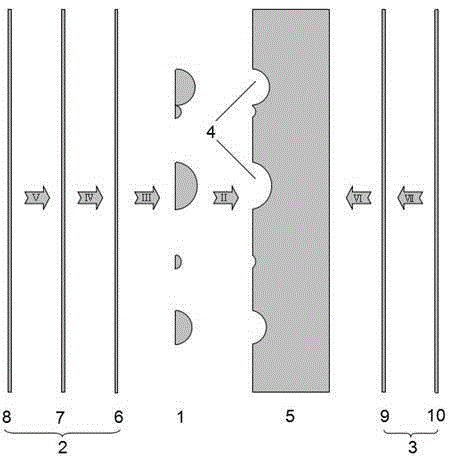

[0034] Such as figure 1 As shown, a steel storage tank corrosion pit repair and tank body reinforcement, including: aluminum material 1 to fill the pit, aluminum anti-corrosion coating 2 on the inner surface of the tank that is in direct contact with the storage material, and a pressure sharing device Carbon fiber cloth reinforcement layer 3 on the outer surface of the tank.

[0035] Concrete construction process of the present invention is as follows:

[0036] 1) Use scraping or shoveling, grinding, and high-pressure water gun to spray dilute acid or alkali solution to clean the tank wall pits and the dirt within 5 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com