Manufacturing method of infrared detector based on temporary release protective layer

A technology for infrared detectors and manufacturing methods, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., and can solve problems such as adiabatic and thermal time constant disadvantages, structure and process complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The preferred embodiments of the infrared detector manufacturing method provided by the present invention will be described in detail below in conjunction with the accompanying drawings, in order to further illustrate the technical methods and effects of the present invention.

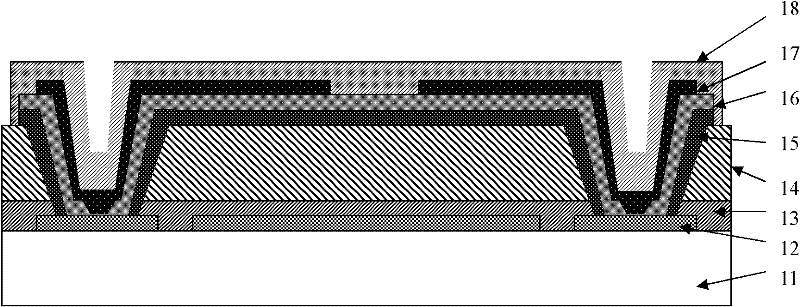

[0053] figure 1 It is a sectional view of the infrared detector of the present invention. The infrared detector includes: a semiconductor substrate 11, a metal layer 12, a dielectric layer 13, a sacrificial layer 14, a first temporary release protection layer 15, a sensitive layer 16, a metal electrode layer 17, The second layer temporarily releases the protective layer 18 .

[0054] Figure 2 is figure 1 The flowchart of the processing method of the infrared detector is shown. The infrared detector processing method of the present invention will be described in detail below in conjunction with FIG. 2 , and the present invention will be further described.

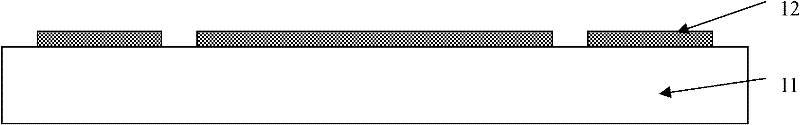

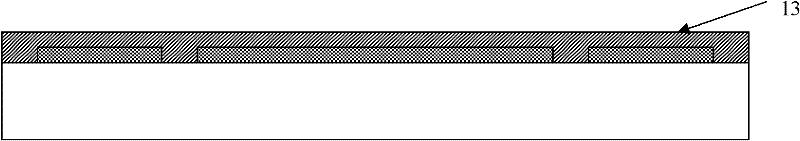

[0055] 2(a), fabricating and patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com