Photoresist-removing method

An object, plasma technology, applied in the direction of photosensitive material processing, etc., can solve the problems of long time, low-k material protective layer loss, low reaction rate, etc., to achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

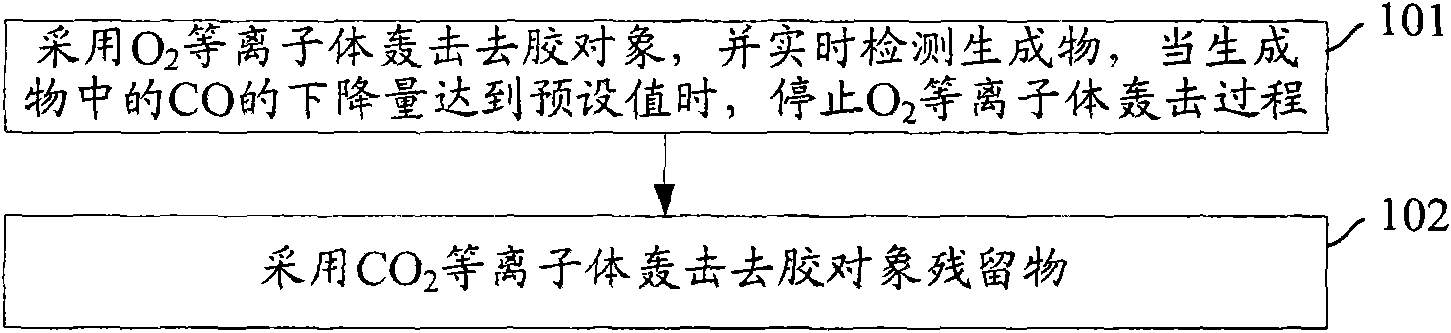

[0032] figure 1 The flow chart of the degumming method provided by the embodiment of the present invention, wherein the degumming object is located above the low-k value interlayer medium, such as figure 1 As shown, the specific steps are as follows:

[0033] Step 101: Adopt O 2 Plasma bombards the object to be glued, and detects the product in real time. When the drop of CO in the product reaches the preset value, stop O 2 Plasma bombardment process.

[0034] The optical emission spectrum can be used to detect the signal value of the product, and the CO signal is sampled according to the preset sampling frequency, for example: 5 times / second. When it is found that the range of the CO signal changes within the first preset time, such as: 3 seconds When it is within the preset range, it is determined that the CO signal is stable, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com