Preparation method of super-hydrophobic and super-oleophobic surface with micro-nano composite structure

A super-hydrophobic, super-oleophobic, micro-nano composite structure technology, applied in the direction of micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problem of hindering Cassie state stability, difficult micro-column sidewall smoothness, and difficult uniform gel formation Uniform film layer and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

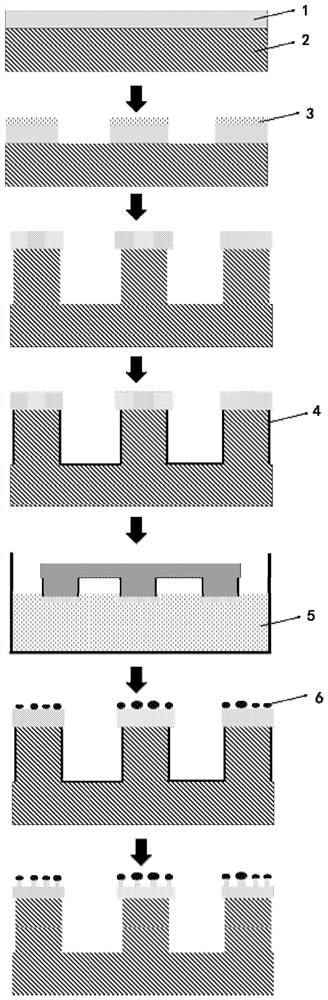

[0032] Such as figure 1 As shown, this embodiment provides a method for preparing a super-hydrophobic and super-oleophobic surface with a micro-nano composite structure. The specific preparation steps are as follows:

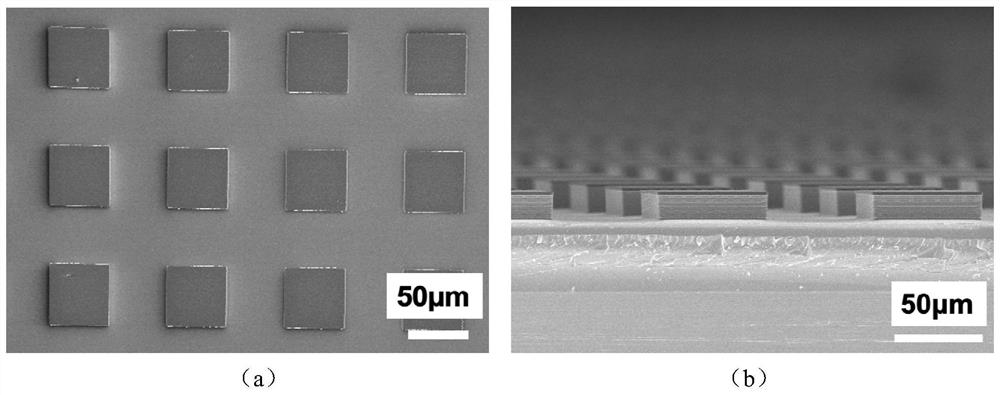

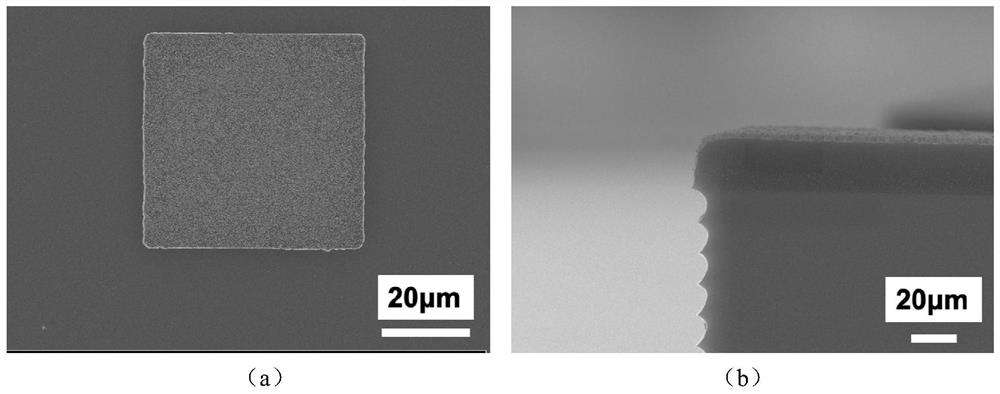

[0033] 1. Preparation of hanging micron square pillars: use ordinary silicon wafer 2 (n or p type, no requirements for resistivity, crystal orientation, etc.) to spin-coat photoresist 1 at a rate of 4000r / s, time 40s, film thickness 1.5μm. Take a square photolithography mask 3 with a line width of 50 μm and a period of 100 μm and perform photolithography to obtain a square column of photoresist with a line width of 50 μm and a period of 100 μm. Use photoresist as a mask for deep silicon etching, and the etching gas is SF 6 , the shielding gas is C 4 f 8 , with a depth of 10 μm, an array of overhanging micron square pillars was obtained.

[0034] 2. Anti-sticking at the bottom of the side wall of the micron square column: first use the ICP-RIE (ULVAC, CE-300I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com