Method for forming fine patterns of semiconductor device using directed self assembly process

A technology of directional self-assembly and fine patterning, which is applied in semiconductor/solid-state device manufacturing, microstructure technology, and photolithography on patterned surfaces, etc. It can solve the problems of forming slot defects, the whole process is intricate, hardened patterns are difficult to remove, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1 and comparative example 1

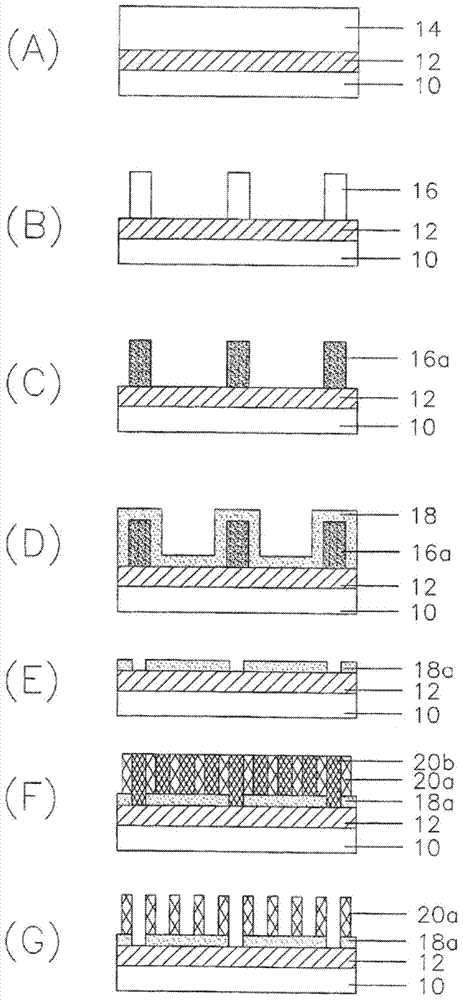

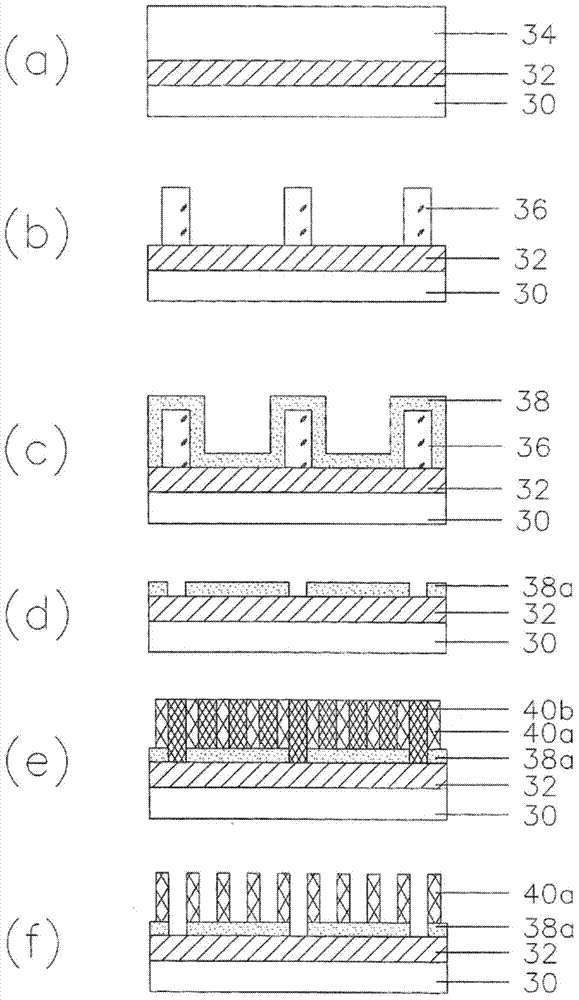

[0024] [Example 1 and Comparative Example 1] Formation of fine patterns of semiconductor devices and their evaluation

[0025] A 33 nm argon fluoride organic anti-reflection coating composition (DARC-A125, manufactured by Toshin Semicon Co., Ltd.) was coated on the silicon wafer and heated at 240° C. for 60 seconds. A photoresist composition (DHA-7079 (argon fluoride photoresist), manufactured by Toshin Semicon Co., Ltd.) was coated and soft-baked at 105°C for 60 seconds to form a Linewidth photoresist pattern. Next, the wafer was exposed to an argon fluoride photolithography machine with an aperture number of 0.85 (ASML1200, manufactured by ASML) and heated at 95° C. for 60 seconds to amplify acidic substances generated during exposure. The heated wafer was dipped in a negative developing solution (n-butyl acetate) for 60 seconds and developed to form a line and space pattern (guide pattern) with a line width of 70 nm. In Comparative Example 1, after exposing the photoresis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com