Zinc indium sulfide-nitrogen doped graphene foam composite photocatalytic material, and preparation method and application thereof

A nitrogen-doped graphene, composite photocatalysis technology, applied in catalyst activation/preparation, chemical instruments and methods, carbon dioxide reduction method preparation, etc., can solve the problem of low utilization rate, high photogenerated carrier recombination efficiency, and low catalytic activity. and other problems, to achieve the effect of no equipment, high photothermal conversion efficiency, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of indium zinc sulfide-nitrogen-doped graphene composite photocatalytic material, the specific operations are as follows:

[0040] 1) Soak polyurethane sponge (length 2cm, width 2cm; height 2cm) in acetone solvent, place it in an ultrasonic cleaner for ultrasonication, then ultrasonically clean it with deionized water, and dry it for use.

[0041] 2) Put the impurity-removed polyurethane sponge obtained in step 1) into an ultraviolet irradiation machine and irradiate it for 30 minutes at a power of 100W, and cool it for use;

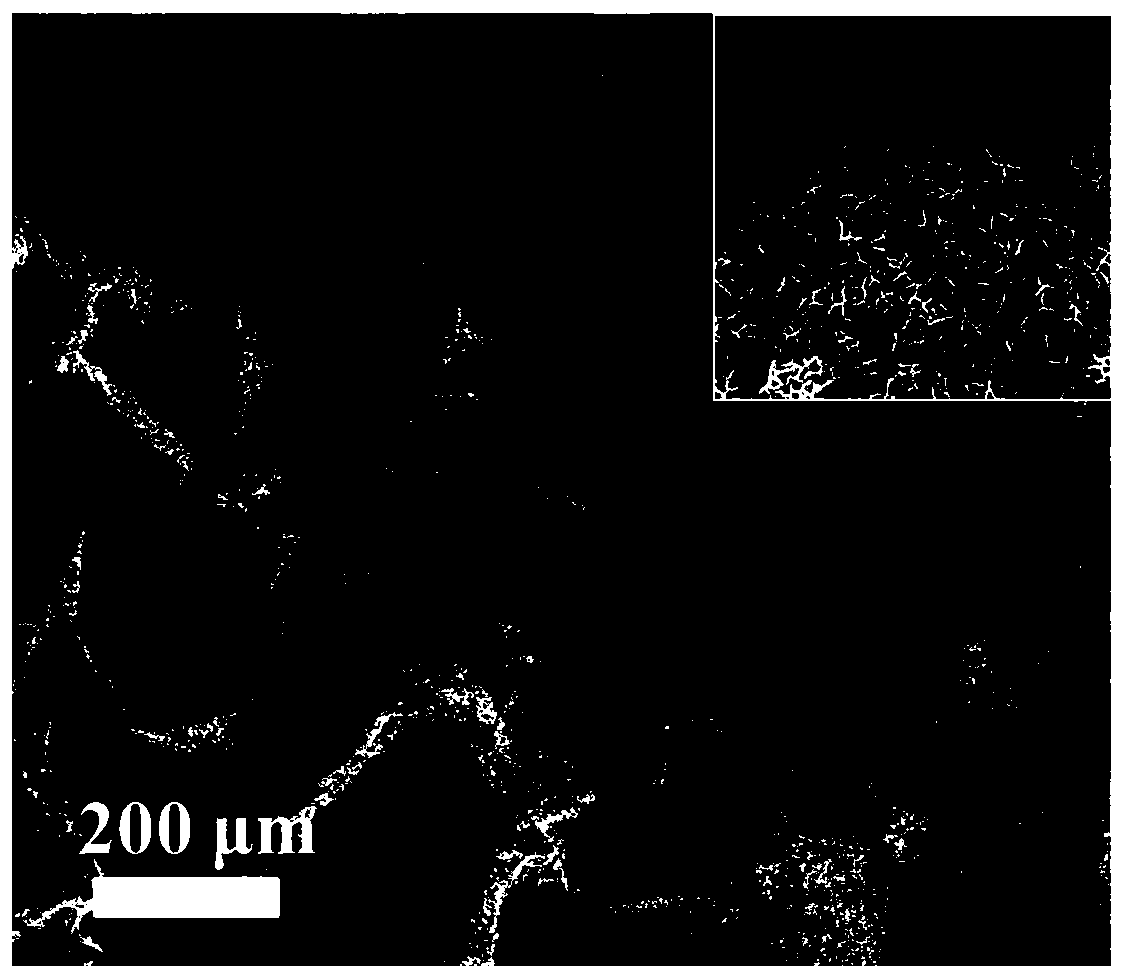

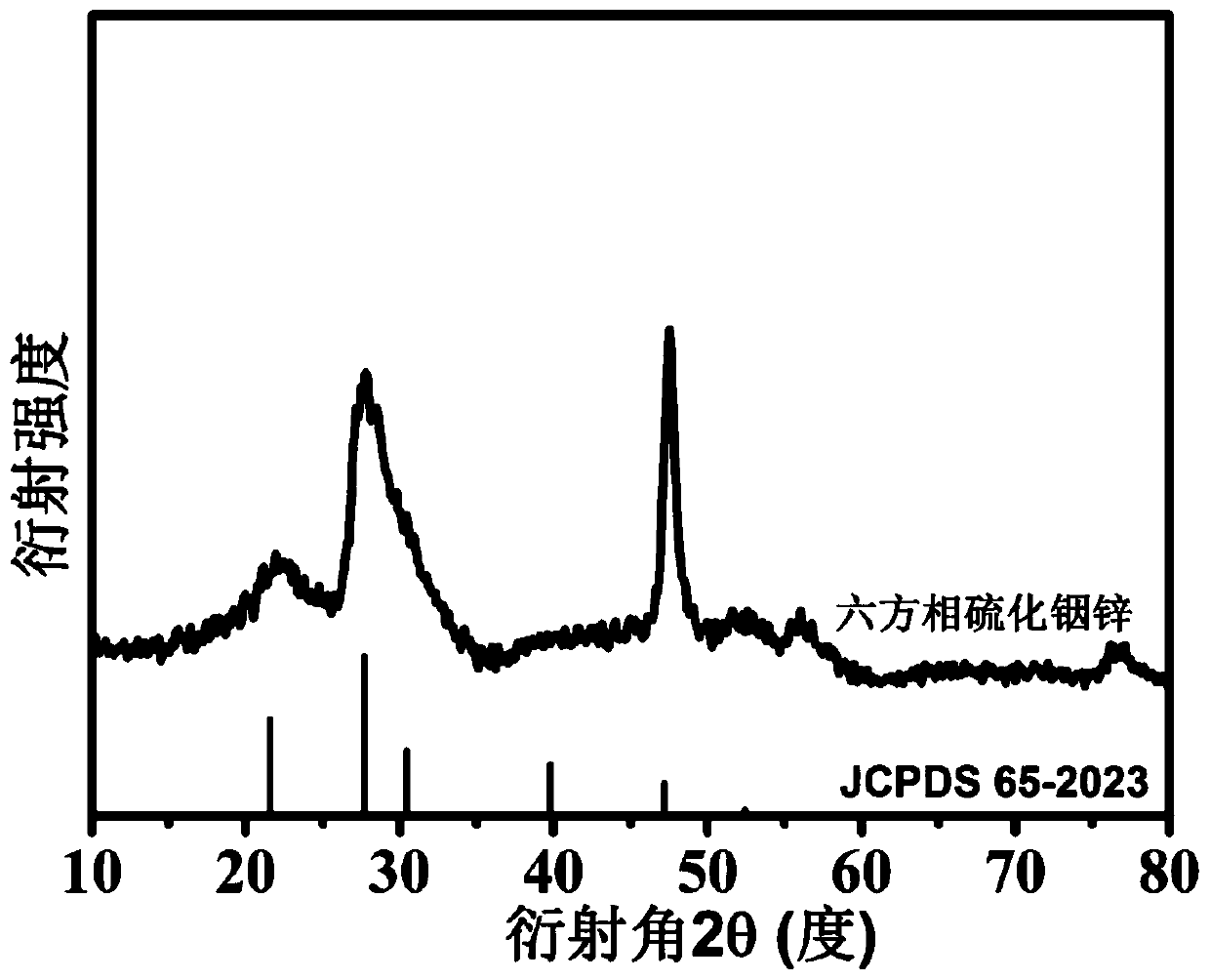

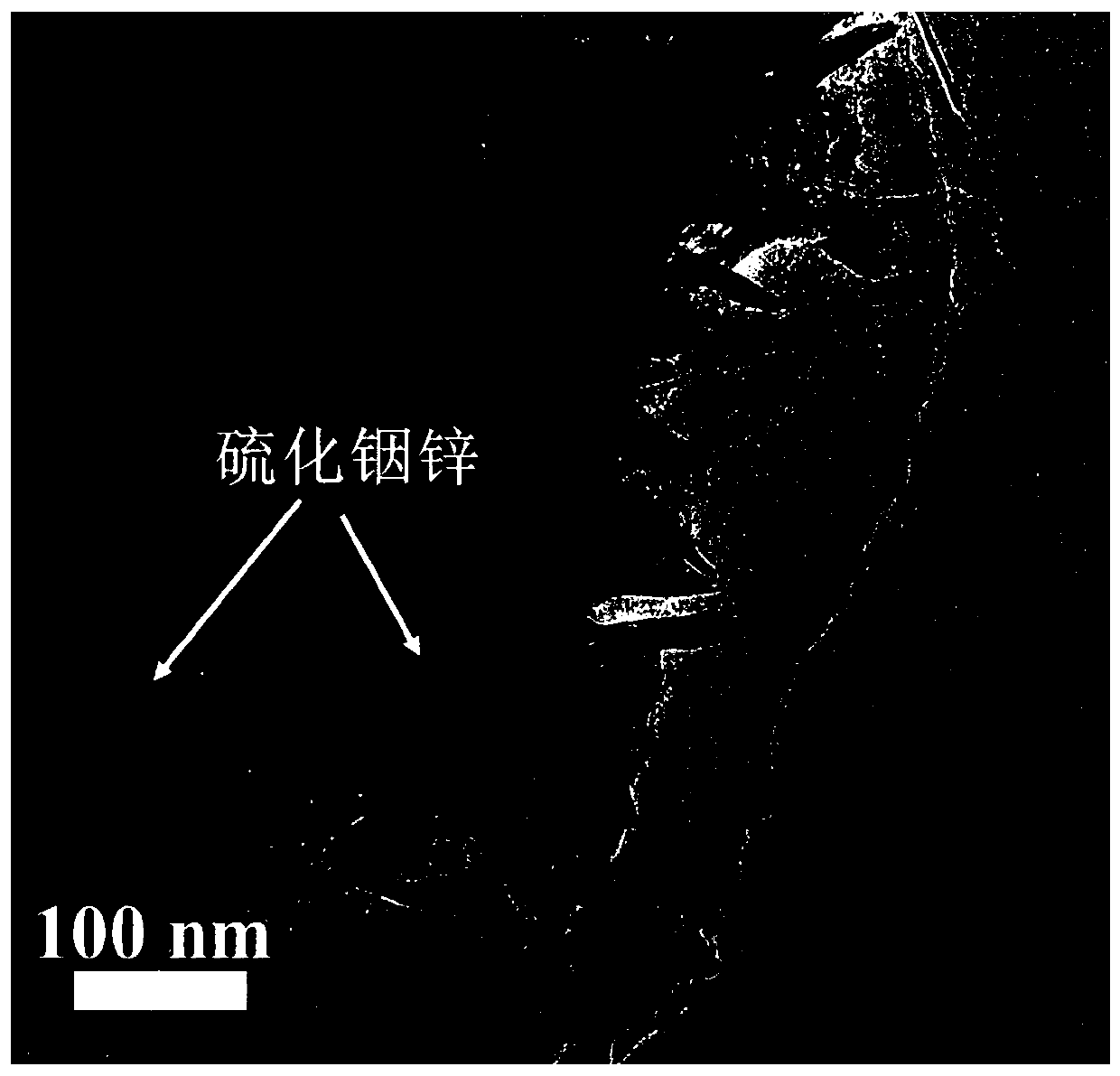

[0042] 3) disperse graphene oxide in a mixed solvent (ethanol volume ratio deionized water volume is 1:1), then place it in an ultrasonic cleaner for ultrasonic dispersion treatment to obtain a uniformly dispersed graphene oxide suspension (0.5mg / mL). Soak 1g of polyurethane sponge treated in step 2) in 50mL graphene oxide suspension, take out the sponge adsorbed with graphene oxide, dry and calcinate at 350°C for 10min to o...

Embodiment 2

[0059] A preparation method of indium zinc sulfide-nitrogen-doped graphene composite photocatalytic material, the specific operations are as follows:

[0060] 1) Soak polyurethane sponge (length 2cm, width 2cm; height 2cm) in acetone solvent, place it in an ultrasonic cleaner for ultrasonication, then ultrasonically clean it with deionized water, and dry it for use.

[0061] 2) Put the impurity-removed polyurethane sponge obtained in step 1) into an ultraviolet irradiation machine and irradiate it for 20 minutes at a power of 200W, and cool it for use;

[0062] 3) disperse graphene oxide in a mixed solvent (ethanol volume ratio deionized water volume is 1:9), then place it in an ultrasonic cleaner for ultrasonic dispersion treatment to obtain a uniformly dispersed graphene oxide suspension (0.5mg / mL). Soak 1g of polyurethane sponge treated in step 2) in 50mL graphene oxide suspension, take out the sponge adsorbed with graphene oxide, dry and calcinate at 350°C for 15min to o...

Embodiment 3

[0066] A preparation method of indium zinc sulfide-nitrogen-doped graphene composite photocatalytic material, the specific operations are as follows:

[0067] 1) Soak polyurethane sponge (length 2cm, width 2cm; height 2cm) in acetone solvent, place it in an ultrasonic cleaner for ultrasonication, then ultrasonically clean it with deionized water, and dry it for use.

[0068] 2) Put the impurity-removed polyurethane sponge obtained in step 1) into an ultraviolet irradiation machine and irradiate it for 20 minutes at a power of 250W, and cool it for use;

[0069] 3) disperse graphene oxide in a mixed solvent (ethanol volume ratio deionized water volume is 1:2), then place it in an ultrasonic cleaner for ultrasonic dispersion treatment to obtain a uniformly dispersed graphene oxide suspension (1.0mg / mL). Soak 1g of polyurethane sponge treated in step 2) in 50mL graphene oxide suspension, take out the sponge adsorbed with graphene oxide, dry and calcinate at 350°C for 20min to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com