Diamond and GaN wafer direct bonding method

A direct bonding, diamond technology, used in electrical components, electrical solid-state devices, semiconductor/solid-state device manufacturing, etc., to achieve the effect of reducing device size and improving radio frequency and power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

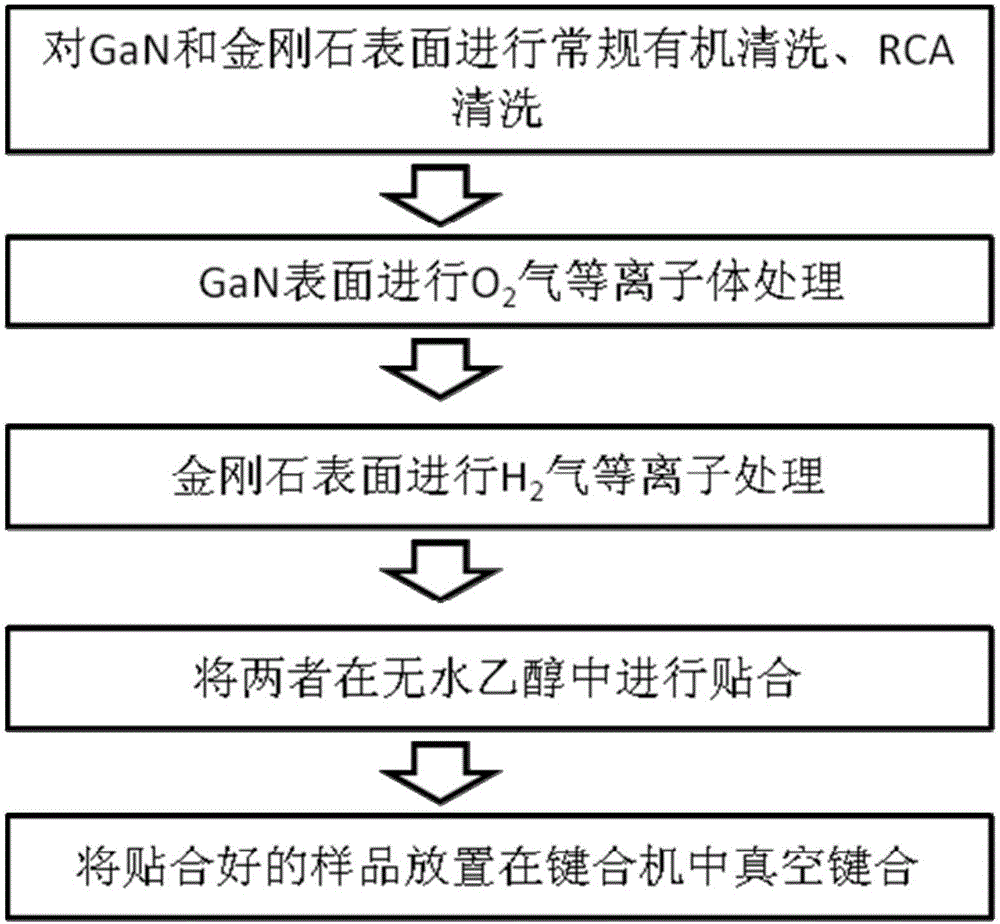

[0015] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following in conjunction with specific examples, and with reference to the appended figure 1 , to further describe the present invention in detail.

[0016] Such as figure 1 As shown, the present embodiment provides a method for direct bonding of diamond and GaN wafers, the method comprising the following steps: (1) carrying out organic cleaning and RCA cleaning on the surface of diamond and GaN; (2) cleaning the surface of GaN carry out O 2 Gas plasma treatment; (3) H2 gas plasma treatment is carried out on the diamond surface; (4) The two are bonded in absolute ethanol;

[0017] (5) Place the bonded samples in a bonding machine for bonding under a high-temperature vacuum environment.

[0018] In the present embodiment, the processing condition of carrying out oxygen plasma treatment to GaN surface in step (2) is: O 2 =30sccm, RF power is 50W, pressure is 2Par. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com