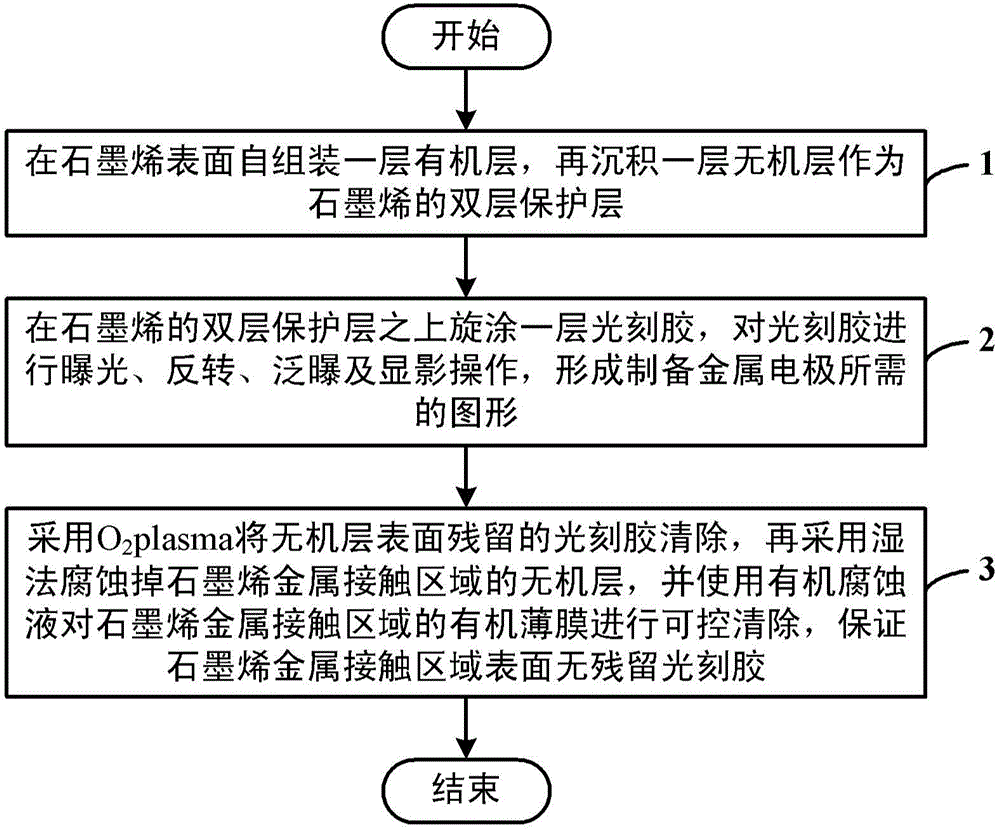

Method for controllably removing residual optical photoresist in graphene-metal contact region

A technology of metal contact and photoresist, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of discounting graphene's electrical properties, restricting application development, hindering the contact between metal and graphene, and reducing doping Effects of complexity, high carrier mobility, and device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

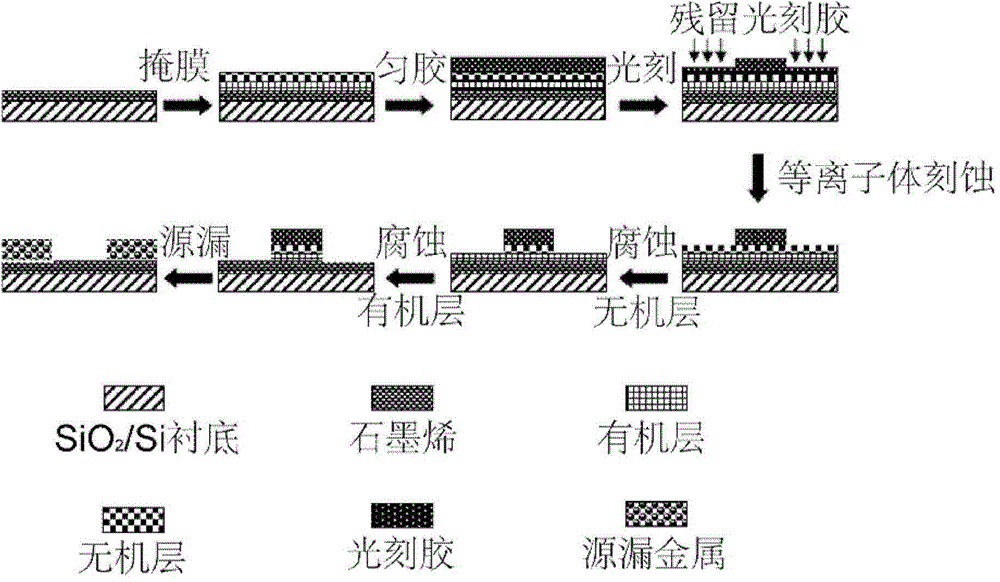

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1. Using polystyrene as the organic layer and metallic nickel as the inorganic layer as the double-shielding layer, the controllable removal of the residual optical photoresist in the double-layer graphene-metal contact area.

[0043] Specific steps are as follows:

[0044] Step 1: Grow a single layer of uniform graphene on the surface of copper foil by CVD method, spin-coat PMMA photoresist on the surface of graphene and heat and bake to cure the photoresist, and then place the copper sheet with graphene and PMMA into a copper etching solution, etch away the copper and transfer it to a silicon dioxide semiconductor substrate with a 300 nm insulating layer.

[0045] Step 2: On 300nm SiO spread with graphene (transferred twice) 2 Spin-coat a layer of 9912 photoresist with a thickness of 1.4 μm on the surface of / Si substrate, after exposure (light intensity 5, time 15s), development (40s), primer, acetone to remove the glue, and graphene into the active area ...

Embodiment 2

[0053] Embodiment 2, using polystyrene as the organic layer, metal nickel as the inorganic layer as the double shielding layer, controllably removes the residual optical photoresist in the graphene-metal contact area.

[0054] The specific steps are similar to those in Example 1, but in step 3, the thickness of polystyrene is 20nm, and the corrosion rate is 1nm / min; in step 4, the thickness of metal nickel is 20nm, and the corrosion rate is 1nm / min.

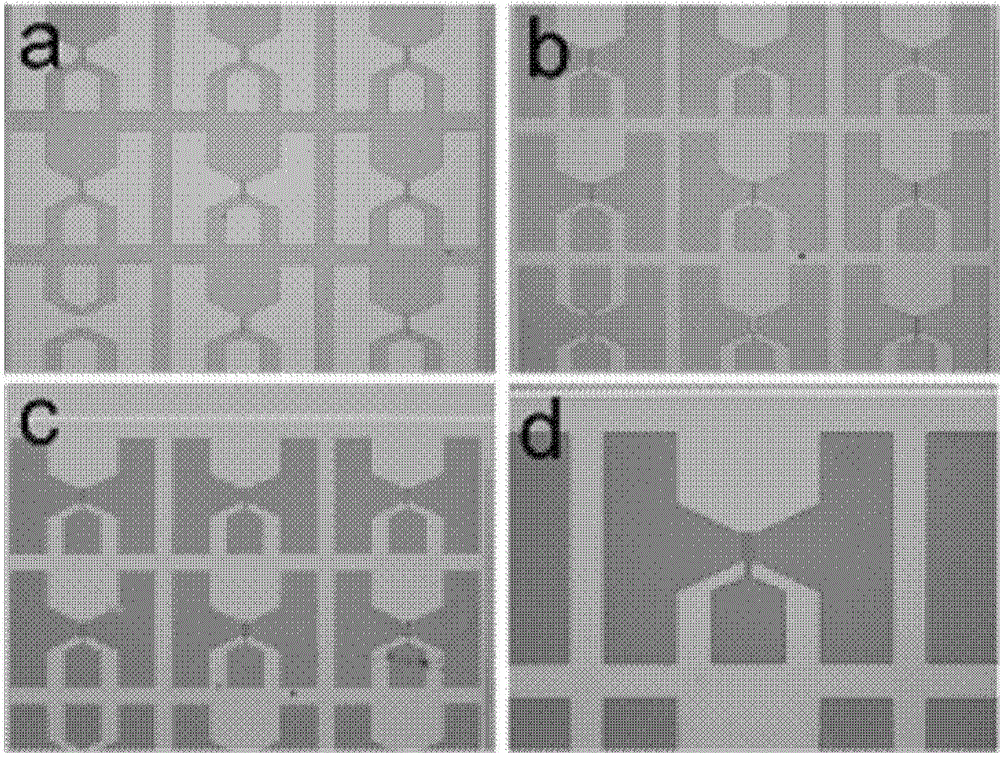

[0055] Image 6 Be the optical picture in the removal process in embodiment 2, Image 6 The optical photos show that the corrosion rate of the protective layer plays a decisive role in maintaining the integrity of the photolithographic pattern. If the corrosion rate is too fast, the capillary phenomenon is relatively obvious, resulting in the loss of the photolithographic pattern.

Embodiment 3

[0056] Embodiment 3, using polyethylene as the organic layer and metal nickel as the inorganic layer as the double shielding layer, controllably removes the residual optical photoresist in the graphene-metal contact area.

[0057] The specific steps are similar to Example 1, but step 3 uses polyethylene as an organic mask layer with a thickness of 20nm and an etching rate of 1nm / min. In step 4, the thickness of metal nickel is 20nm and the etching rate is 1nm / min.

[0058] Figure 7 For the electrical characteristics of graphene field effect transistor in embodiment 3, Figure 7 The transfer curve shows that the corrosion rate is too fast and the device performance is not good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com