Silicon wafer pressure setting and applying clamp for plasma etcher

An etching machine and plasma technology, applied in the direction of discharge tube, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of inconsistent etching effect, inaccurate control of product quality, inability of pressurization device to pressurize accurately, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

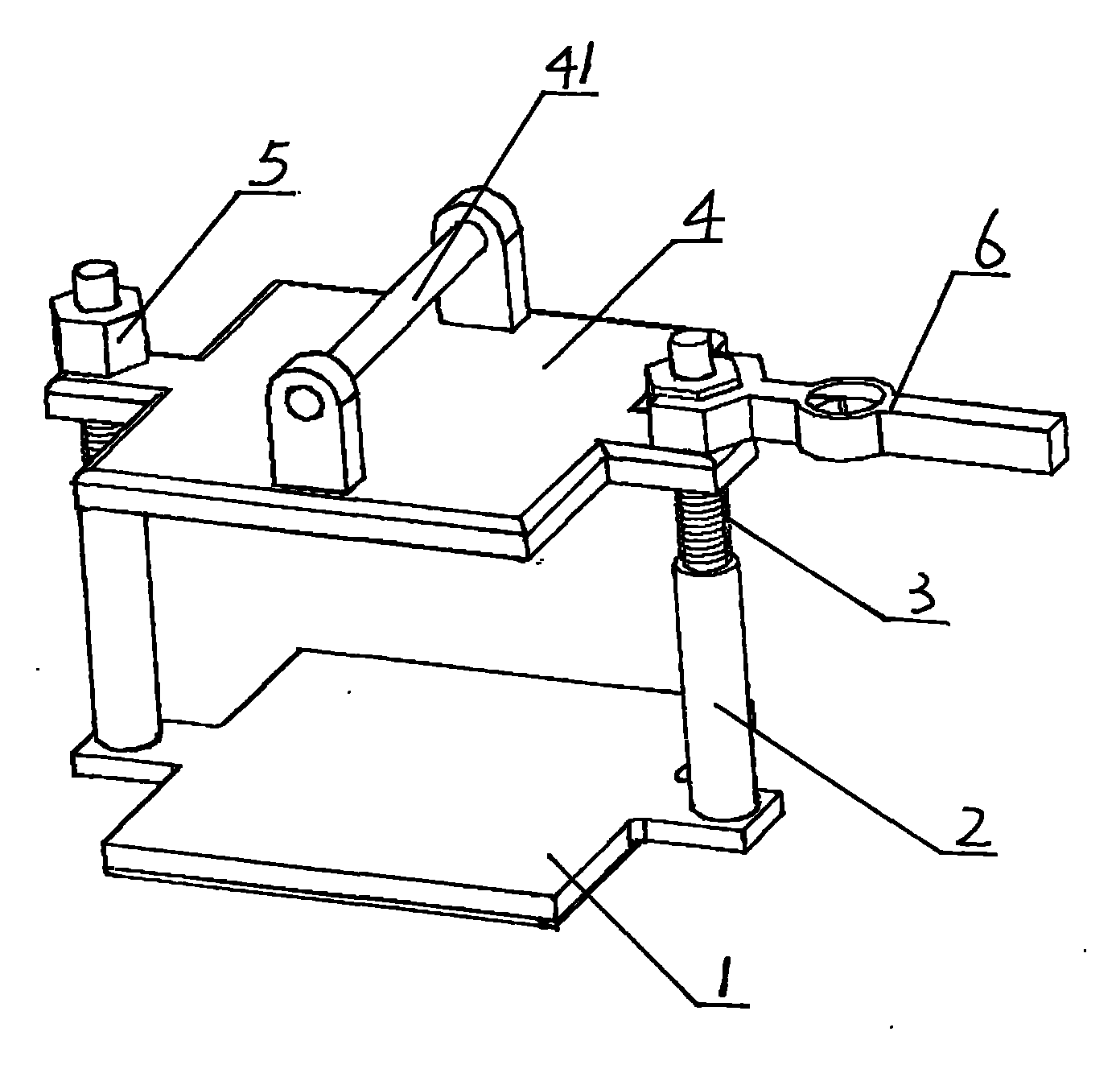

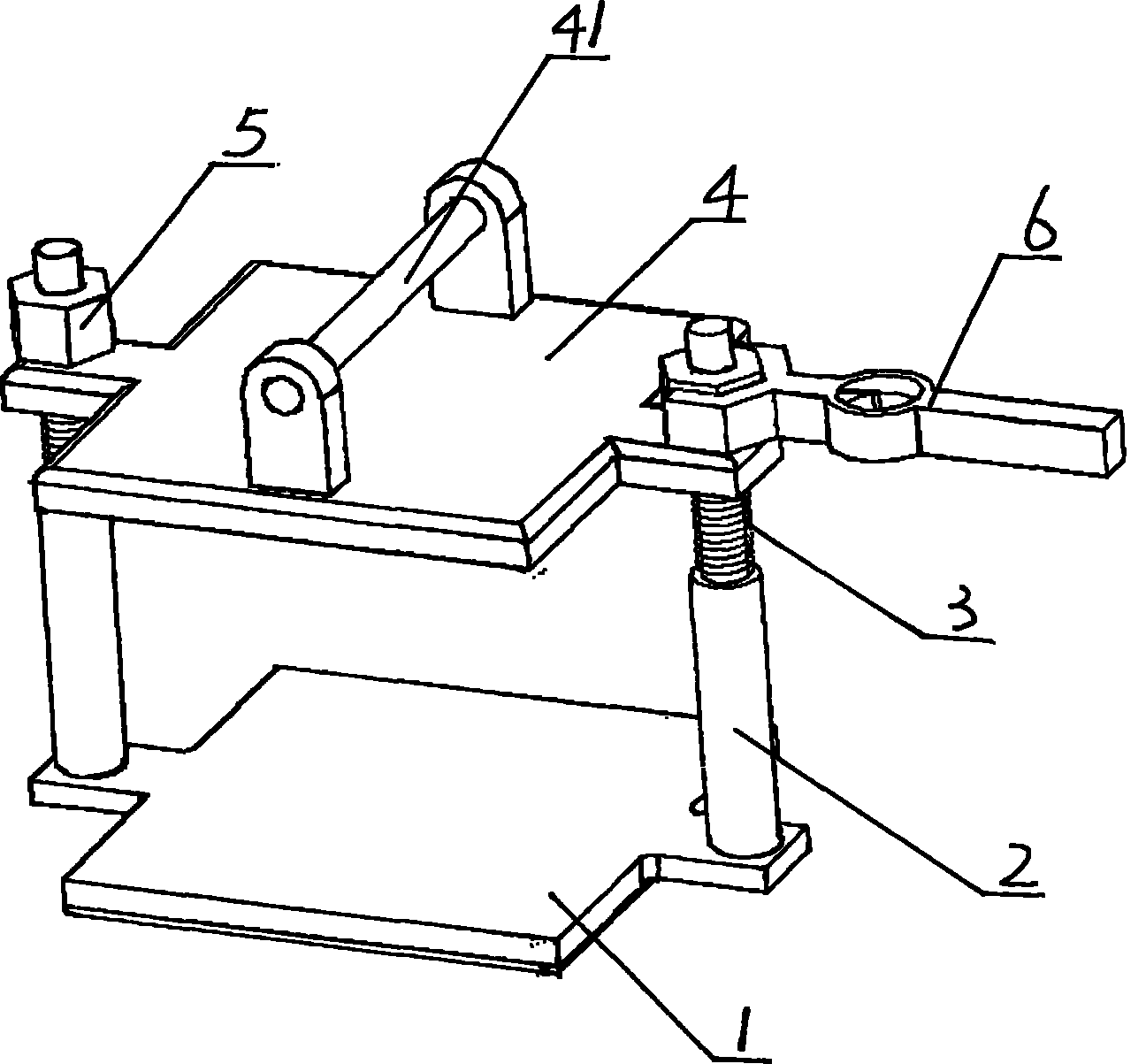

[0012] The silicon chip constant pressure pressure clamp of the plasma etching machine is composed of a clamp body 1, a column screw 2, a return spring 3, a pressure plate 4, a tightening nut 5 and a numerical control torque wrench 6, and the lower ends of the two column screws 2 are Fixed on the clamp body 1, threads are provided on the upper sections of the two column screws 2, the return spring 3 is set on the upper section of the column screws 2, and the pressure plate 4 is provided with a handle 41 and ear seats corresponding to the two column screws 2 , the pressure plate 4 is set on the two column screws 2 through the two ear seats, and is tightened by the tightening nut 5, and the tightening nut 5 is tightened by a numerical control torque wrench 6 with a fixed torque.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com