Equipment for guiding propping agents into underground fractured strata under drive of high-energy air flow

A technology of high-energy gas flow and proppant, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems that the fracturing effect is not obvious, the flow conductivity cannot be enhanced, and the high-energy gas fracturing effect cannot be controlled in real time, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

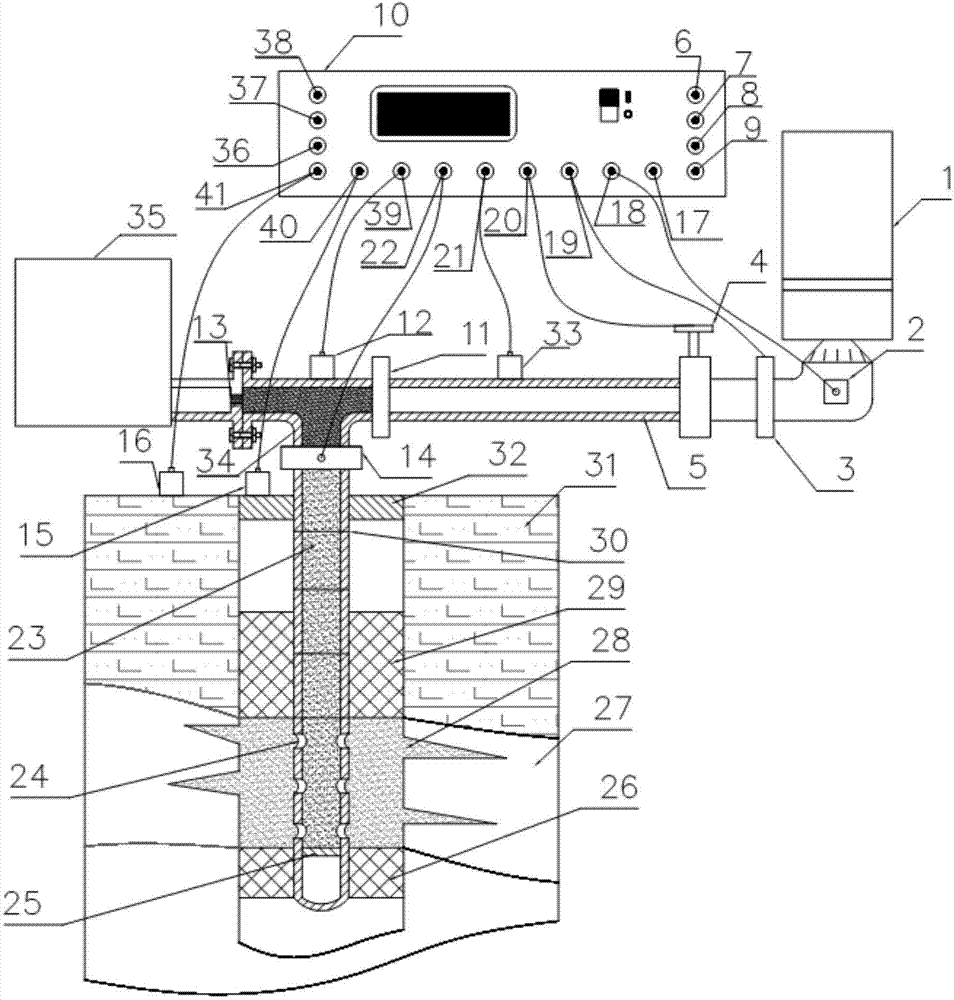

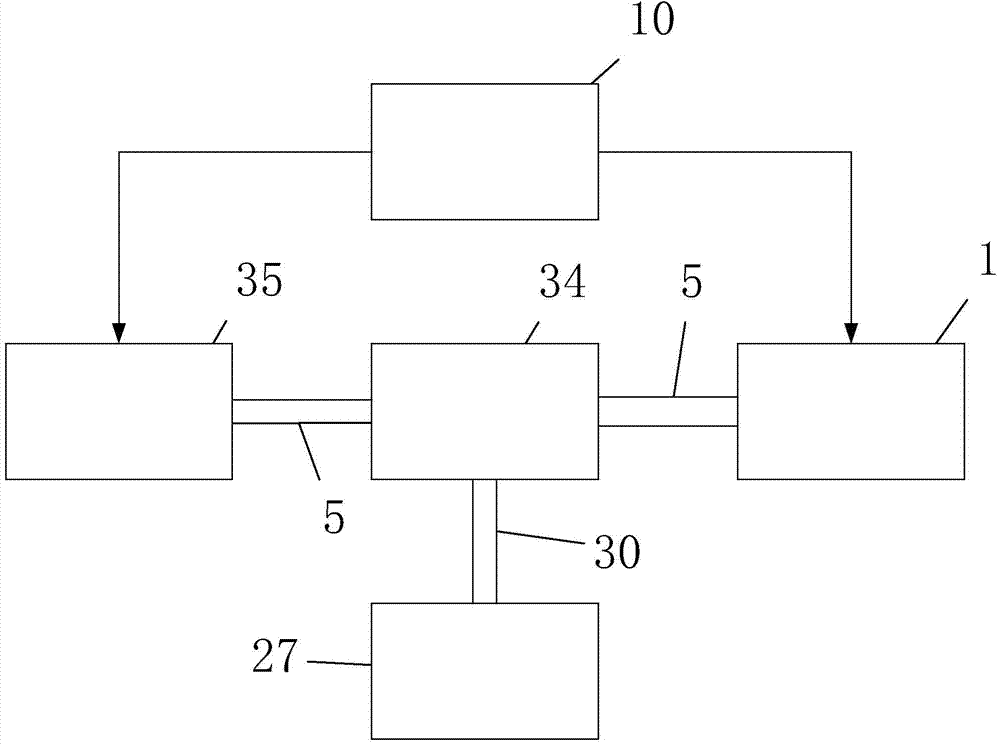

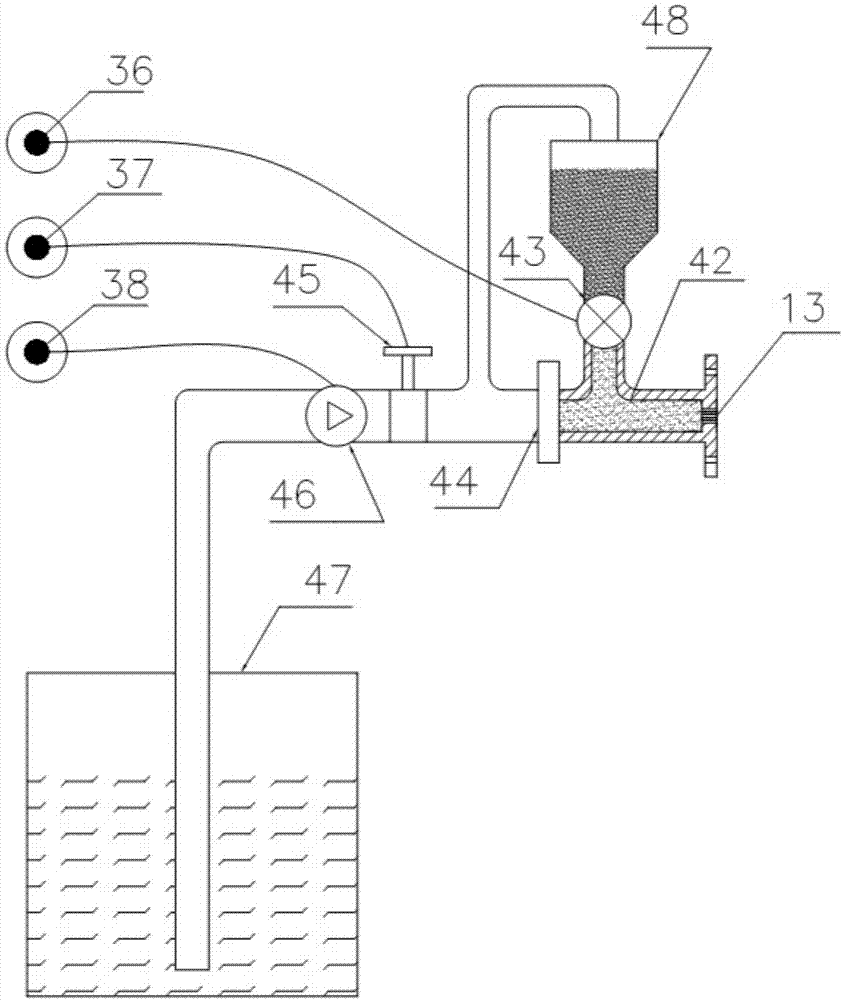

[0029] Example 1. High-energy gas flow drives proppant into the equipment for downhole fracturing formation

[0030] The high-energy gas flow-driven proppant introduced into downhole fracturing formation equipment in this example is a special equipment that uses high-energy gas flow to drive proppant fracturing formation. The specific structure of the equipment is as follows: Figure 1 to Figure 8 joint show, figure 1 The overall structure diagram of the equipment for driving proppant into the downhole fracturing formation by high-energy gas flow, figure 2 It is a block diagram of the equipment structure for high-energy gas flow driving proppant into downhole fracturing formation. In the two figures: 1 is the high-energy gas eruption mechanism, 2 is the nozzle temperature sensor, 3 is the nozzle flow sensor, 4 is the pressure relief valve, and 5 is the ground guidance Pipeline, 6 is the control end of the oxidant valve, 7 is the control end of the reducing agent valve, 8 is ...

Embodiment 2

[0031] Example 2. High-energy gas flow drives proppant into the equipment for downhole fracturing formation

[0032] The specific structure of the high-energy gas flow-driven proppant introduced into the downhole fracturing formation in this example is available Figure 1 to Figure 8 etc. have jointly shown that the equipment for introducing proppant into downhole fracturing formations driven by high-energy gas flow in this example differs from the equipment for introducing proppant into downhole fracturing formations driven by high-energy gas flow in Example 1. After the four fuels of fuel, catalyst and additive are sprayed into the high-energy gas combustion chamber in proportion and mixed, they can burn by themselves without ignition plug ignition. In this case, the high-energy gas combustion chamber may not be provided with an ignition plug and its control. 2. The main control microprocessor of this example selects and adopts the microprocessor of MSP430 type, or AVR type,...

Embodiment 3

[0033] Example 3. High-energy gas flow drives proppant into the equipment for downhole fracturing formation

[0034] The specific structure of the high-energy gas flow-driven proppant introduced into the downhole fracturing formation in this example is available Figure 1 to Figure 8 etc. have jointly shown that the equipment for introducing proppant into downhole fracturing formations driven by high-energy gas flow in this example differs from the equipment for introducing proppant into downhole fracturing formations driven by high-energy gas flow in Embodiments 1 and 2 in the following points: 1. In this example The oxidizing agent is liquid oxygen. The reducing agent of this example is selected to adopt hydrazine, or methylhydrazine, or unsymmetrical dimethylhydrazine, or mixed hydrazine-50. The catalyzer of this example selects and adopts ferric chloride hydrate etc. The additive of this example selects to adopt methyl alcohol or furfuryl alcohol. 2. The proppant of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com