Fully decoupled electro-hydraulic brake system

A technology of hydraulic braking and complete decoupling, applied in the direction of brakes, brake transmission devices, braking action starting devices, etc., can solve the problem of inability to actively control the pedal force of the driver, the high-pressure accumulator is afraid of vibration, and the maintenance cost is expensive. and other problems, to achieve the effect of simple structure, reduced leakage hidden danger, cost and maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

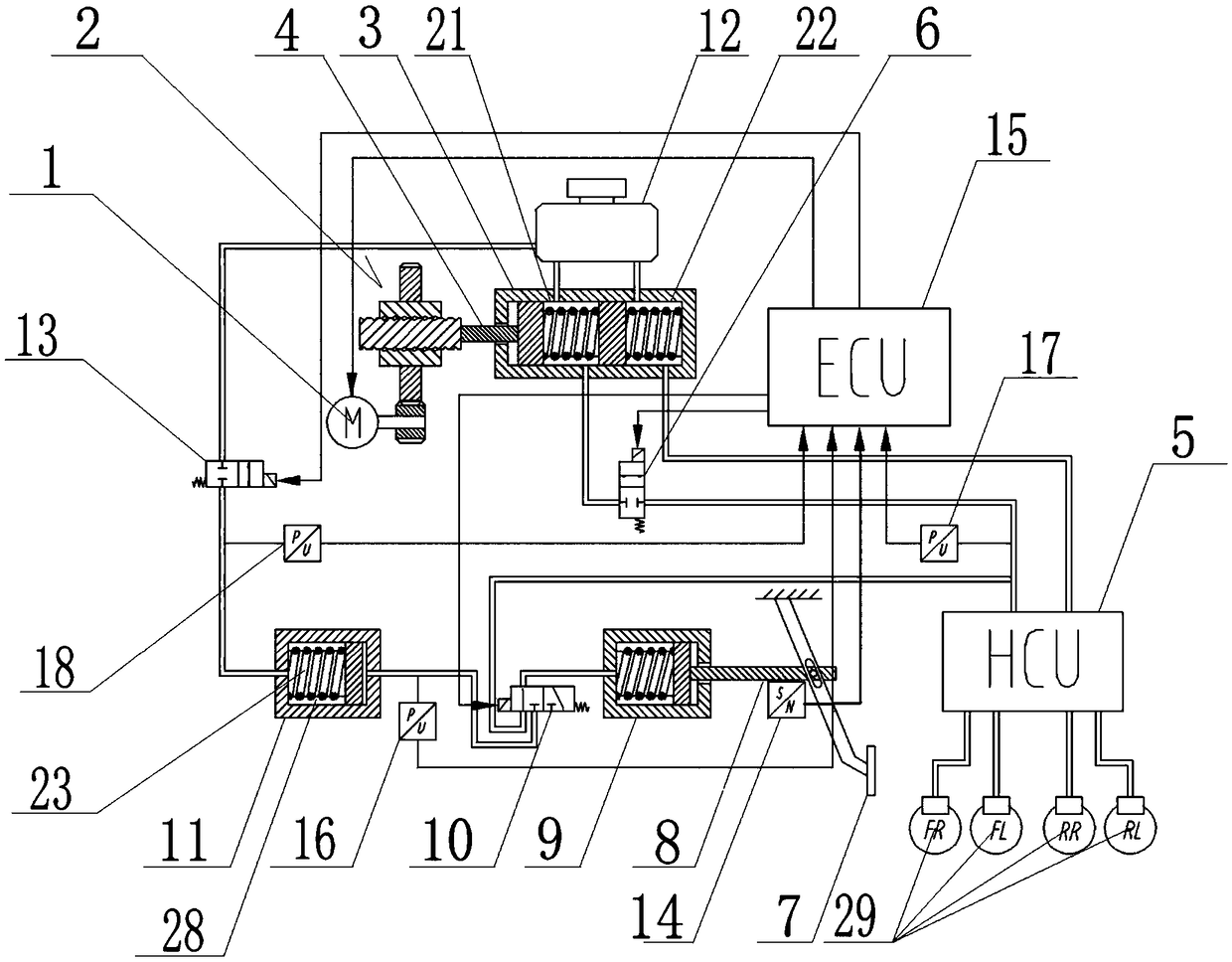

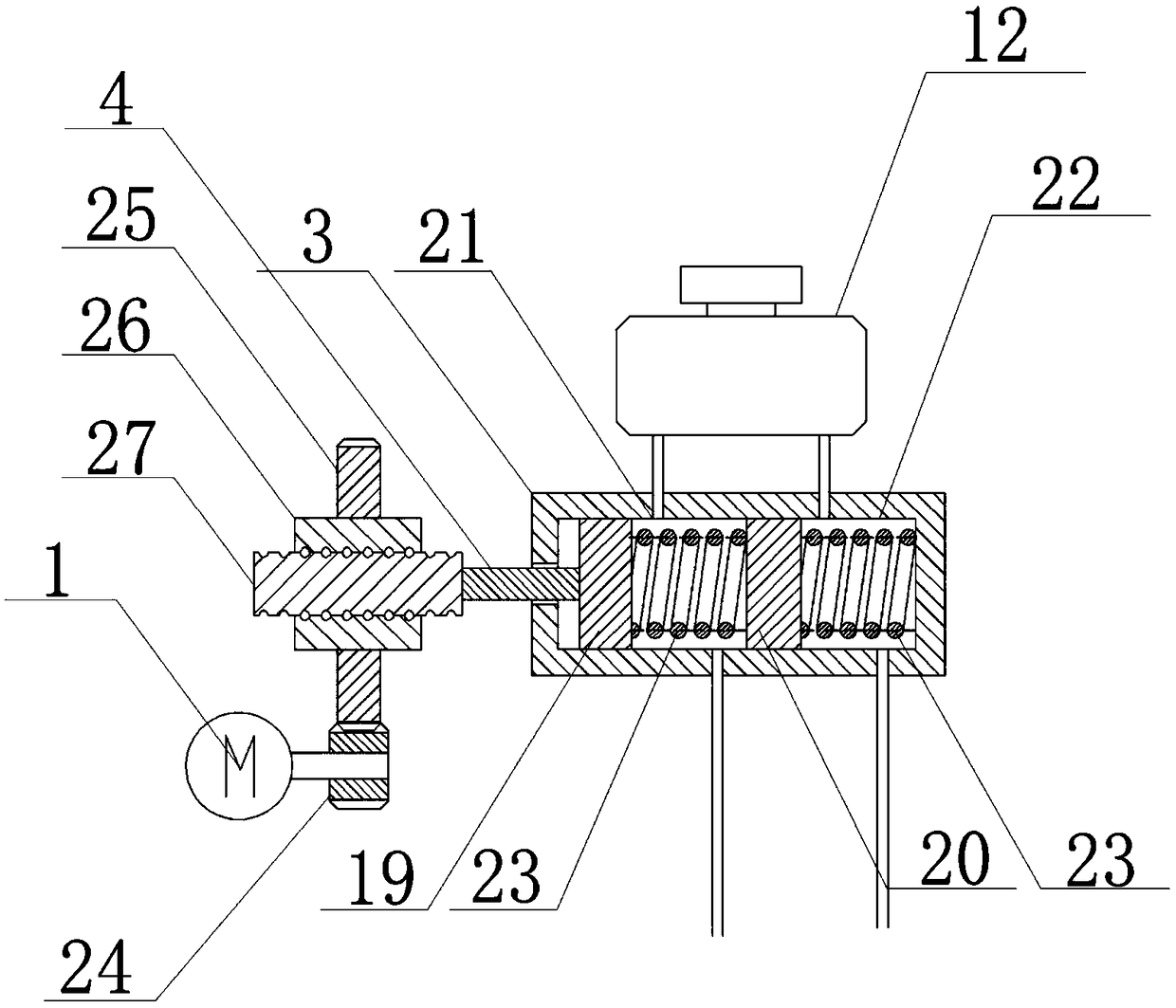

[0048] see Figure 1 to Figure 2 Shown:

[0049] The present invention includes a booster motor 1, a booster transmission assembly 2, a brake master cylinder 3, a piston push rod 4, a hydraulic control unit HCU5, a normally closed solenoid valve A6, a brake pedal 7, a pedal push rod 8, a human hydraulic cylinder 9, two Position three-way solenoid valve 10, pedal feeling simulator 11, liquid storage tank 12, normally closed solenoid valve B13, pedal stroke sensor 14 and electronic control unit ECU15:

[0050] The booster motor 1 is connected to the piston push rod 4 of the brake master cylinder 3 through the booster transmission assembly 2, the liquid outlet of the brake master cylinder 3 is connected to the hydraulic control unit HCU5 through a hydraulic pipeline, and the normally closed solenoid valve A6 is set to On the hydraulic pipeline connected between the brake master cylinder 3 and the hydraulic control unit HCU5;

[0051] The brake pedal 7 is connected to the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com