Inductive coupling plasma etching machine platform and electrode arrangement thereof

A technology of plasma etching and inductive coupling, which is applied in the direction of plasma, circuits, electrical components, etc. It can solve the problems of non-volatile etching products, increased machine maintenance, and reduced machine capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

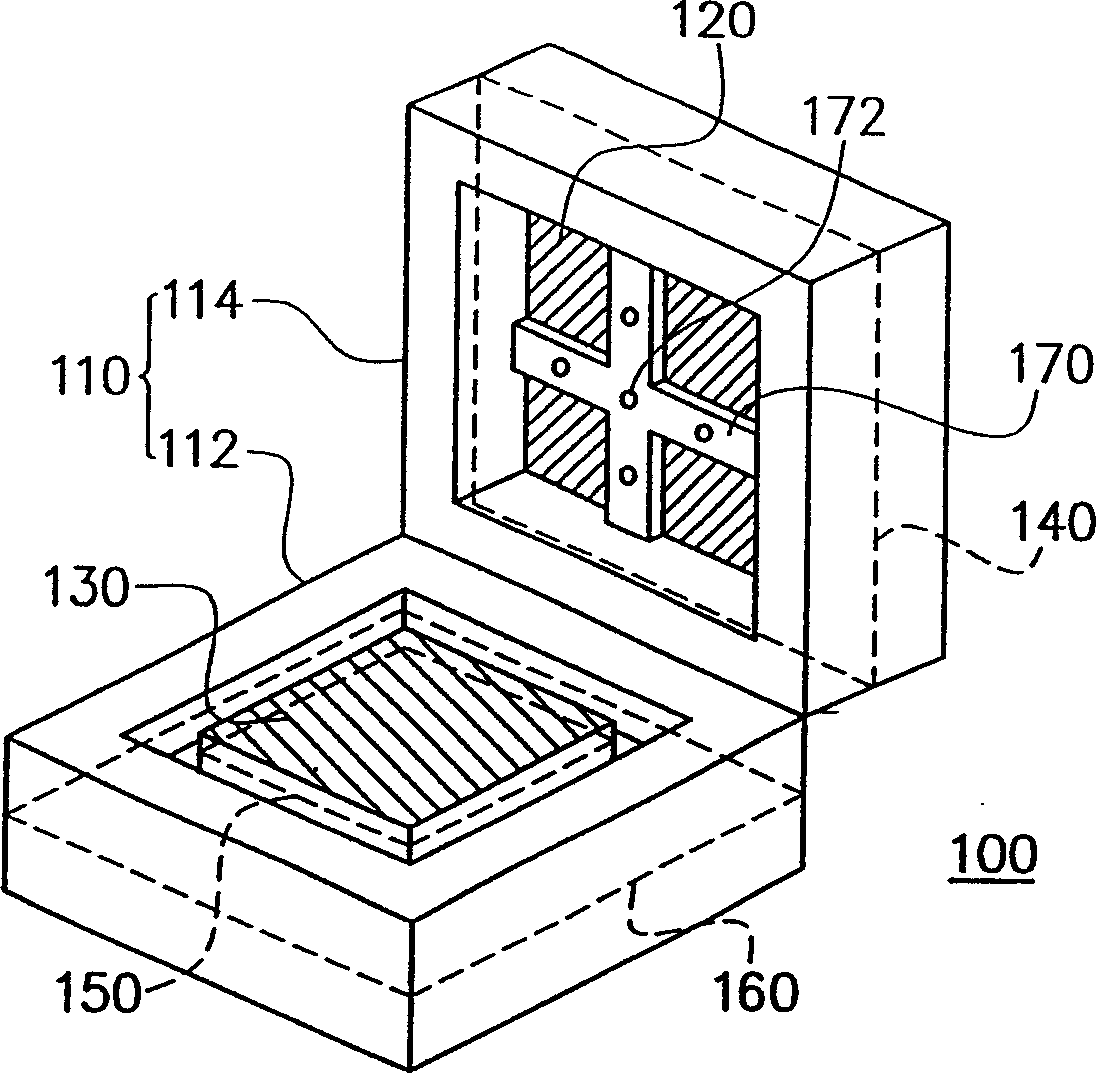

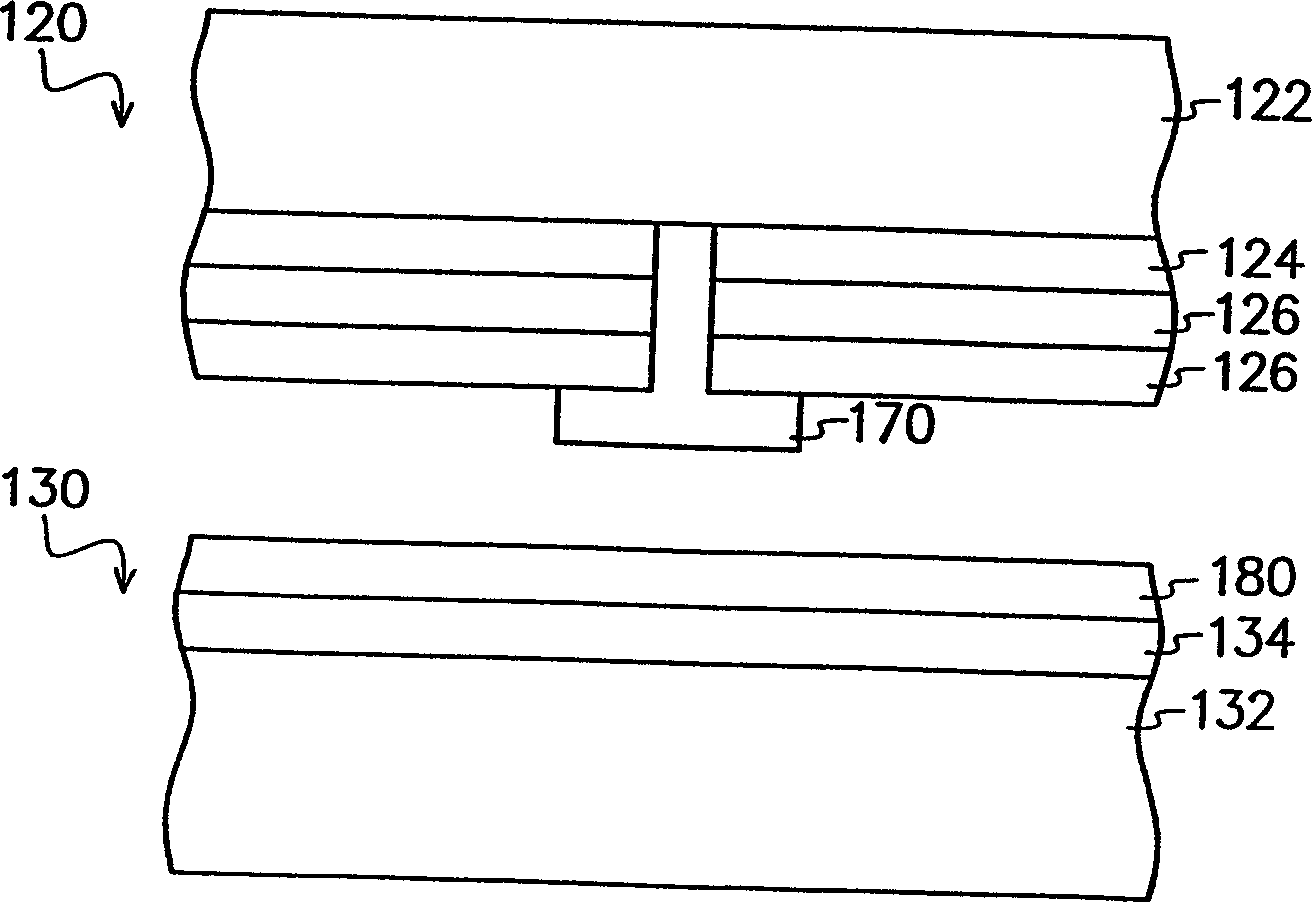

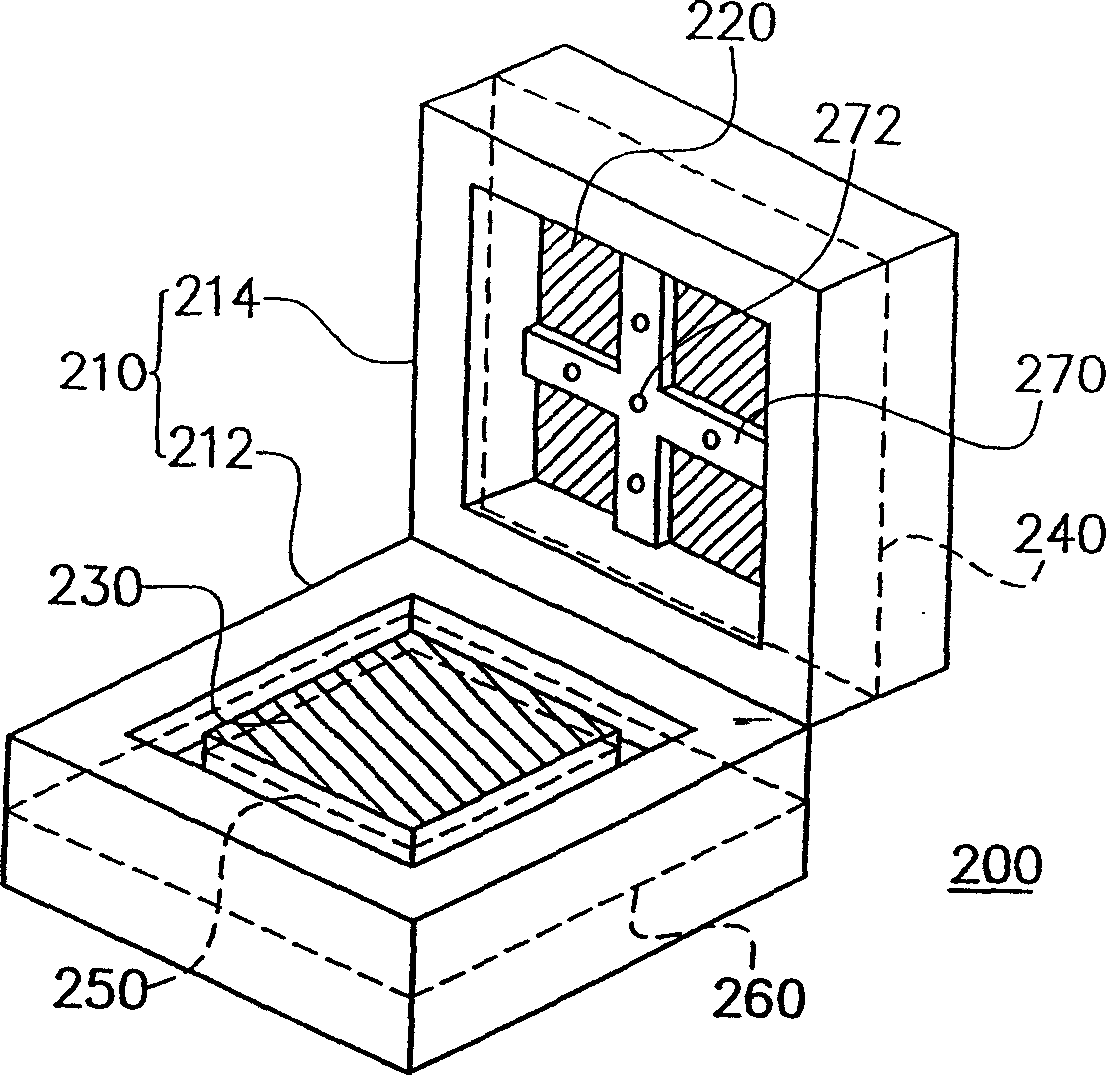

[0037] Figure 2A It is a schematic diagram of an inductively coupled plasma etching machine according to a preferred embodiment of the present invention. Please refer to Figure 2A , the inductively coupled plasma etching machine 200 is composed of a reaction chamber 210, an upper electrode 220, a lower electrode 230, an upper temperature control device 240, a lower temperature control system 250, a side wall temperature control system 260 and a gas supply device 270 constituted. Wherein, the reaction chamber 210 is composed of, for example, a cavity 212 and an upper cover 214 , and the upper cover 214 and the cavity 212 are connected to each other, and the upper cover 214 can be lifted or closed relative to the cavity 212 . The upper electrode 220 is disposed in the reaction chamber 210, such as disposed on the inner surface of the upper cover 214, and the lower electrode 230 is disposed in the reaction chamber 210, such as disposed on the inner surface of the cavity 212, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com