Electrode of plasma etcher for carrying out dry etching on hard inorganic material substrate

A technology of inorganic materials and plasma, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of complex structure and incapable of large-scale production, and achieve the effect of simple and reliable structure, which is conducive to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

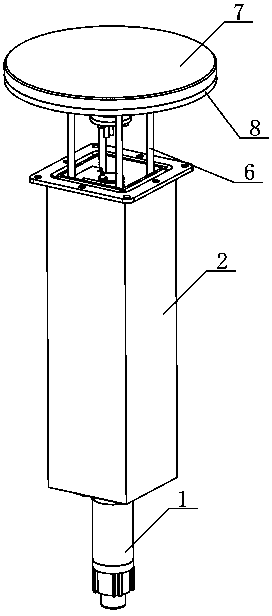

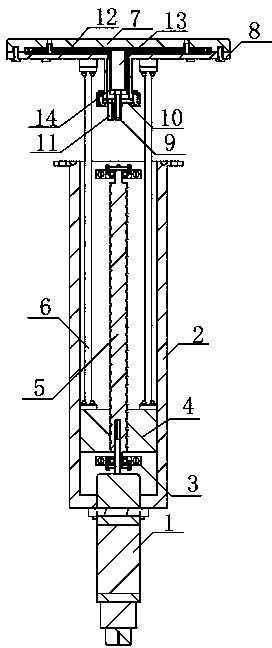

[0036] refer to figure 1 , figure 2 , an electrode of a plasma etching machine for dry etching hard inorganic material substrates, including a guide rail 2 for fixed connection with an etching chamber, and a lifter that can move up and down inside the guide rail 2 is installed. A lower electrode tray is fixedly connected to the lifter 4, and the lower electrode tray is arranged above the guide rail 2, and the lower electrode tray includes a fixedly connected top plate 7 and a bottom plate 8, and the top plate 7 There is a cylindrical groove in the lower part of the cylinder, and the gas distribution plate 12 is fixedly installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com