Brazing technique for 6061 aluminum alloy and AZ31B magnesium alloy

A brazing process, magnesium alloy technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problem of easy corrosion of magnesium alloys, and achieve the effect of easy cutting, uniform wall thickness, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

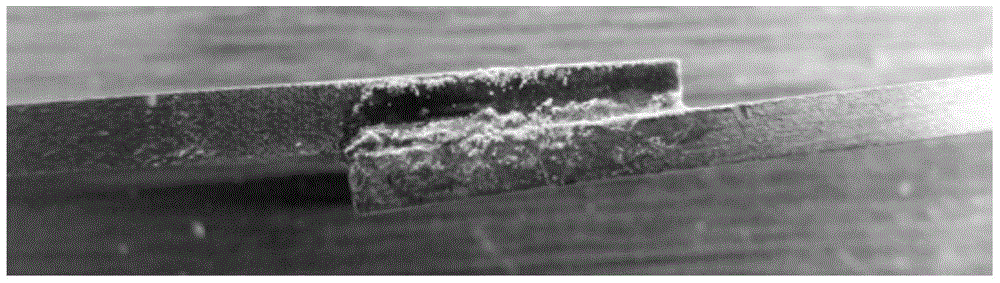

Image

Examples

Embodiment

[0026] Embodiment: The aluminum alloy used in this example is 6061 forged aluminum alloy, and the magnesium alloy is ZA31B magnesium alloy for the test.

[0027] a. For 6061 aluminum alloy containing chemical mass percentage Mg (0.8% ~ 1.2%), Mn 0.2%, Si<0.1%, Fe<0.03%, Cu<0.1%, Ni<0.005% , Ca < 0.04%, other elements < 0.3%, and the rest is Mg. The brazing filler metal is sheet-shaped Zn-12Cd brazing filler metal, and the chemical mass percentage of the brazing filler metal is Cd (10% to 12%), Ag (5.2% to 6.4%), Cu (1% to 2.4%), the rest is Zn, check whether the content of the raw material quality certificate is correct, then check the appearance quality of the raw material, and finally re-inspect the chemical composition and mechanical properties.

[0028] b. Use sandpaper to strictly grind off the oxide skin on the surface of 6061 aluminum alloy, AZ31B magnesium alloy and flaky solder Zn-12Cd to improve the quality of welding;

[0029] c. Rinse off the debris on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com