Patents

Literature

89 results about "6005 aluminium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

6005 aluminium alloy is an alloy in the wrought aluminium-magnesium-silicon family (6000 or 6xxx series). It is closely related, but not identical, to 6005A aluminium alloy. The main difference between the two alloys is that 6005 has a higher minimum composition percentage of aluminium than 6005A (while having essentially the same maximum). The most common forming method is extrusion. It can also be forged or rolled, but as a wrought alloy it is not used in casting. It cannot be work hardened, but is commonly heat treated to produce tempers with a higher strength at the expense of ductility.

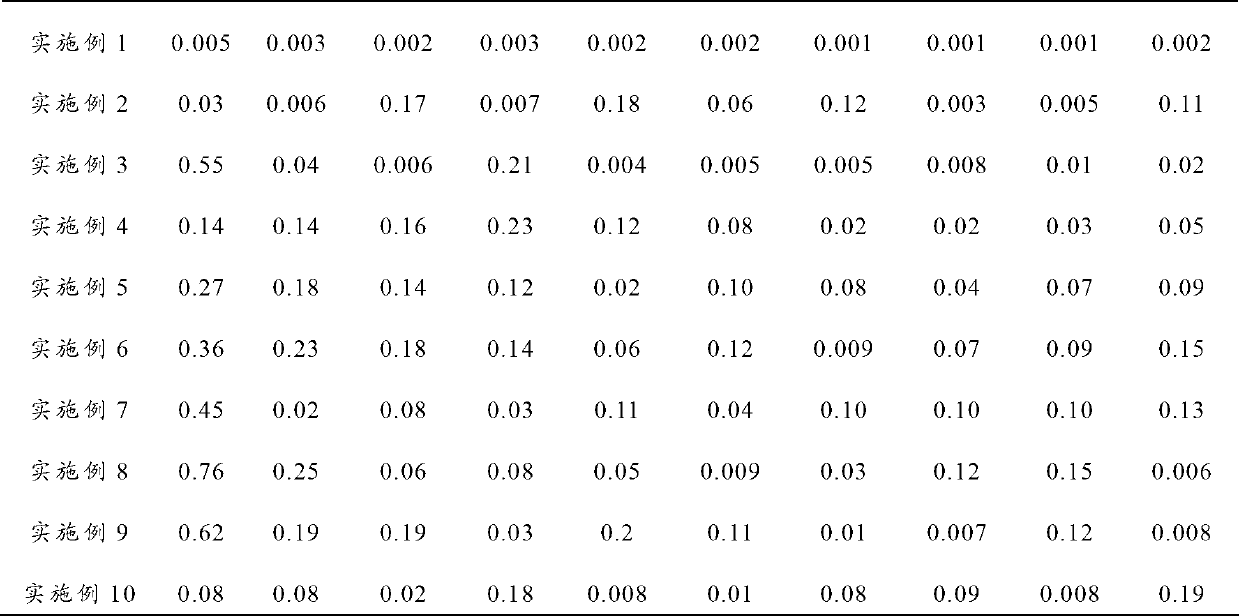

6063 aluminium alloy with high strength and elongation coefficient an dproduction thereof

The invention opened a high strength and high extensibility 6063 Al alloy which contain the Cu, Mn, chrome, Fe, Zn, Ti, Al. The process is: a, founding: adding the material to the furnace melting stir ring and skimming coving refining skimming and refining thermal retardation casting ingot. b extruding and heat processing: isotroping air cooling, heating extruding quenching cutting cooling stretching straightening aging treatment product. The process has improved the mechanics of the alloy, also the elongation percentage (60%) and the intensity (40%). The tensile strength has been improved to 280-300 MPa, the elongation percentage is improved to 13%. So it satisfy the windows and the curtain wall's need.

Owner:CENT SOUTH UNIV +1

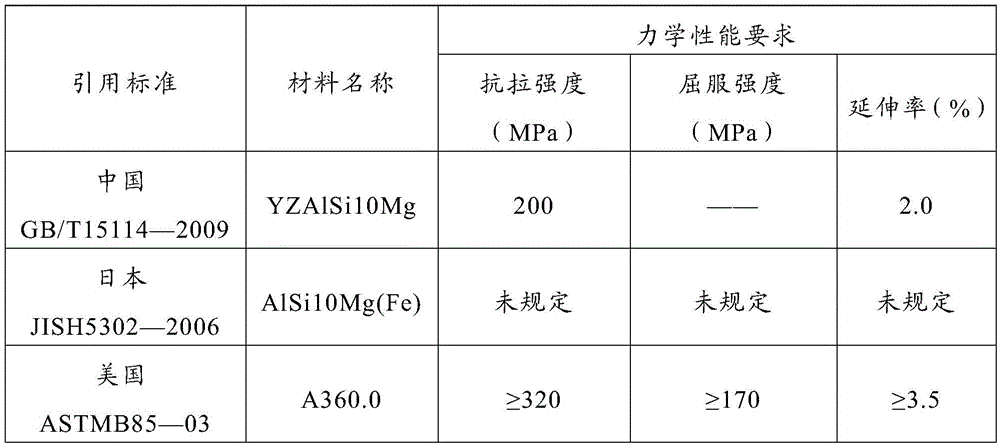

Low pressure casting aluminium alloy for cylinder cap of minicar engine

The present invention relates to a minicar engine cylinder cap low-pressure casting aluminium alloy, and its main chemical components are Si, Cu and Mg, in particular Cu and Mg control is better, and its harmful impurity element control is serious, and after said alloy is undergone the processes of modification treatment by means of modification agent and (T6) heat treatment, its tensile strength QbMPa is greater than or equal to 300, HB is about 110, and said alloy has enough strength and rigidity and good size stability, and said alloy can meet the requirements for miniature car engine cylinder cap low-pressure casting process and mechanical working process.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Preparation method of high-quality 6061 aluminium alloy forging for semiconductor equipment

ActiveCN102644039AImprove qualityEasy to operateMetal-working apparatus5005 aluminium alloyHeat treated

A preparation method of a high-quality 6061 aluminium alloy forging for semiconductor equipment comprises the following steps of: (1) blank making by a common semicontinuous casting method; (2) homogenization heat treatment of 6061 aluminium alloy by two-stage homogenization technology, wherein a first-stage temperature range is 540-570 DEG C, heat preservation time is selected to be 12-24 hours, a second-stage temperature range is 570-620 DEG C, and heat preservation time is selected to be 18-24 hours; (3) forging technology, wherein a preheating temperature of a press chopping block is 300-350 DEG C, the maximal forging heating time is not more than 3 when multi-heating forging is employed, an upsetting forging ratio for each heating is controlled to be 4-6 when forging with 2-3 heating times is employed, the forging ratio is controlled to be 7-9 when forging with one heating time is employed, and the final forging temperature is controlled to be 320-360 DEG C; (4) solid solution aging technology, wherein a solid solution temperature is 520-540 DEG C, heat preservation time is on a basis of 45 min, the heat preservation time increases by 1 min when the thickness of the forging increases by 1 mm, an aging temperature is 160-180 DEG C, and heat preservation time is between 16-25 hours. The invention provides the preparation method of a high-quality 6061 aluminium alloy forging for semiconductor equipment, and the method has the advantages of strong operability, high yield, stable product performance, high product added value, and the like, is applicable to production for small-lot supply, and has significant economic benefits.

Owner:GRIMAT ENG INST CO LTD

Preparation method of 7B04 aluminium alloy section

InactiveCN101760679AGood mechanical propertiesMeet the indicator requirements5005 aluminium alloyIngot

The invention relates to a preparation method of a 7B04 aluminium alloy section, which solves the problems that a large-sized round cast ingot is difficult to form and mechanical property and electrical conductivity can not meet index requirements at the same time in the traditional preparation process of the 7B04 aluminium alloy section. The preparation method comprises the following steps of: 1, smelting the round cast ingot of a casting alloy; 2, uniformly annealing; 3, extruding into the section; 4, quenching; and 5, aging to obtain the 7B04 aluminium alloy section. The 7B04 aluminium alloy section has properties meeting the index requirements, and achieves the finished product ratio more than 80 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Method for casting aluminium alloy

ActiveCN101474668AQuality improvementReduced mobilityFoundry mouldsFoundry cores5005 aluminium alloy6005 aluminium alloy

The invention provides a casting method of aluminum alloys. The method comprises four steps of smelting, refining, moulding and pouring. The casting method is characterized by adding specific additive in the casting process and strictly controlling standing time and casting temperature after refining of aluminum pad to enhance purity of aluminum melt and product quality of the aluminum alloys. The tensile strength, pinhole and the like of the castings which are made by the method are obviously enhanced, and defective index of large aluminum alloy castings made by the method is obviously reduced, and the method is applicable to casting of large aluminum castings with high requirements.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD +1

High-perforance compression casting aluminium alloy

A aluminum alloy material consists of Si 9.5-11.5wt%, Cu 2.0-3.0wt%, Mg 0.3-0.4wt%, mixed rare earth RE 0.1-0.3wt%, Mn is less than or equal to 0.5, Zn is less than or equal to 1.0, Fe is less than or equal to 1.0, Al residue. The mixed rare earth RE consists of La 5-80wt%, Ce 5-40wt%, Nd 1-20wt%, Y 1-20wt%, Pr 1-20wt%. It achieves good flowing, mechanical and cutting machining performance.

Owner:CHONGQING UNIV

Al-Fe-Os-RE aluminium alloy, preparation method thereof and power cable

ActiveCN103103384AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cable5005 aluminium alloy

The invention provides an Al-Fe-Os-RE aluminium alloy and a preparation method thereof. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

Al-Fe-Rh-RE aluminium alloy, preparation method thereof and power cable

ActiveCN103103382AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cable5005 aluminium alloy

The invention provides an Al-Fe-Rh-RE aluminium alloy and a preparation method thereof. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

Heat treatment process for ZL101A aluminium alloy for automobile wheel hub

InactiveCN101880844AReduce energy consumptionShorten heat treatment timeSolution treatmentEnergy consumption

The invention discloses a heat treatment process for a ZL101A aluminium alloy for an automobile wheel hub. The process comprises the following steps of: putting an as-cast blank into a solution treatment furnace for raising temperature, performing solution treatment at a solution temperature, taking the blank out of the solution treatment furnace, quenching the blank, putting the as-cast blank into an ageing treatment furnace for raising the temperature, performing ageing treatment on the blank at an aging treatment temperature; and after taking the blank out of the ageing treatment furnace, cooling the blank in the air medium. The heat treatment process is characterized in that: the solution treatment temperature is 525 to 550 DEG C; the heat maintaining time during the solution treatment is 60 to 120 minutes; the ageing treatment temperature is 165 to 180 DEG C; and the heat maintaining time during the ageing treatment is 90 to 180 minutes. The heat treatment process organically combines the short-time solution treatment and the short-time ageing treatment and fulfils the aim of low energy consumption and high work efficiency. At the same time, compared with the standard T6 heat treatment process, the heat treatment process can shorten the heat treatment time by over one time and guarantee that an alloy microstructure obtained through the solution treatment and the ageing treatment reaches an ideal state of the standard T6 treatment.

Owner:GUANGZHOU KINBON NON FERROUS ALLOY METALS CO LTD +1

Aluminium alloy for use in a brazed assembly

InactiveUS6413331B1Obtain long-life corrosion performanceHigh strengthWelding/cutting media/materialsSoldering media5005 aluminium alloy5052 aluminium alloy

Owner:CORUS ALUMINUM WALPROD

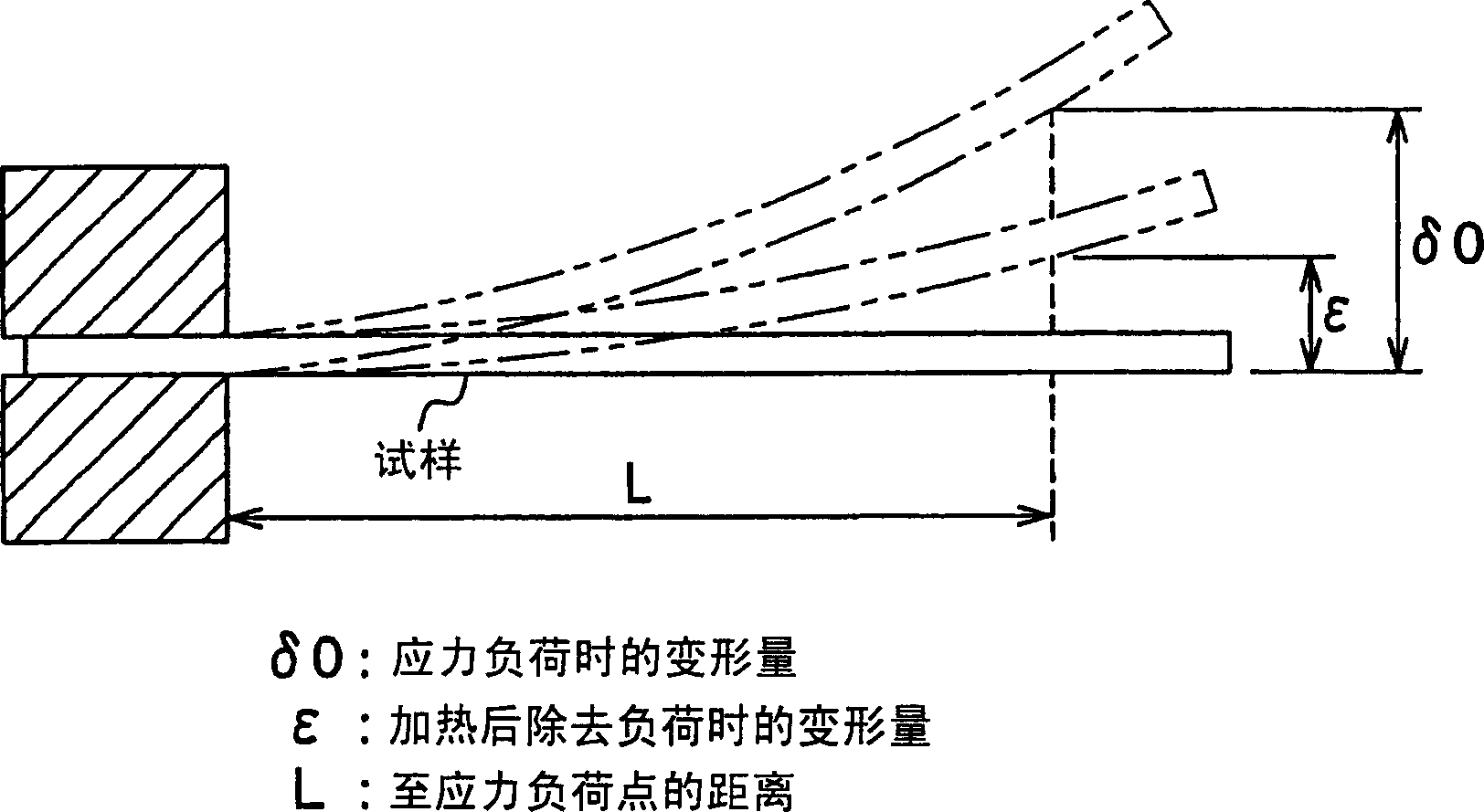

Shaping method of aluminium alloy section

This invention provides a method for molding aluminum alloy. The method comprises: applying more than 1% processing tension on 6000 series aluminum alloy, and heating at 50-150 deg.C for aging and hardening reclamation treatment. Since the moldability of aluminum alloy is reclaimed, thus the aluminum alloy can be molded at ambient conditions. By using this method, the moldability of 6000 series aluminum alloy after aging and hardening at room temperature can be reclaimed.

Owner:KOBE STEEL LTD

Al-Fe-Hf-RE aluminium alloy, preparation method thereof and power cable

ActiveCN103103396AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cable5005 aluminium alloy

The invention provides an Al-Fe-Hf-RE aluminium alloy and a preparation method thereof. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

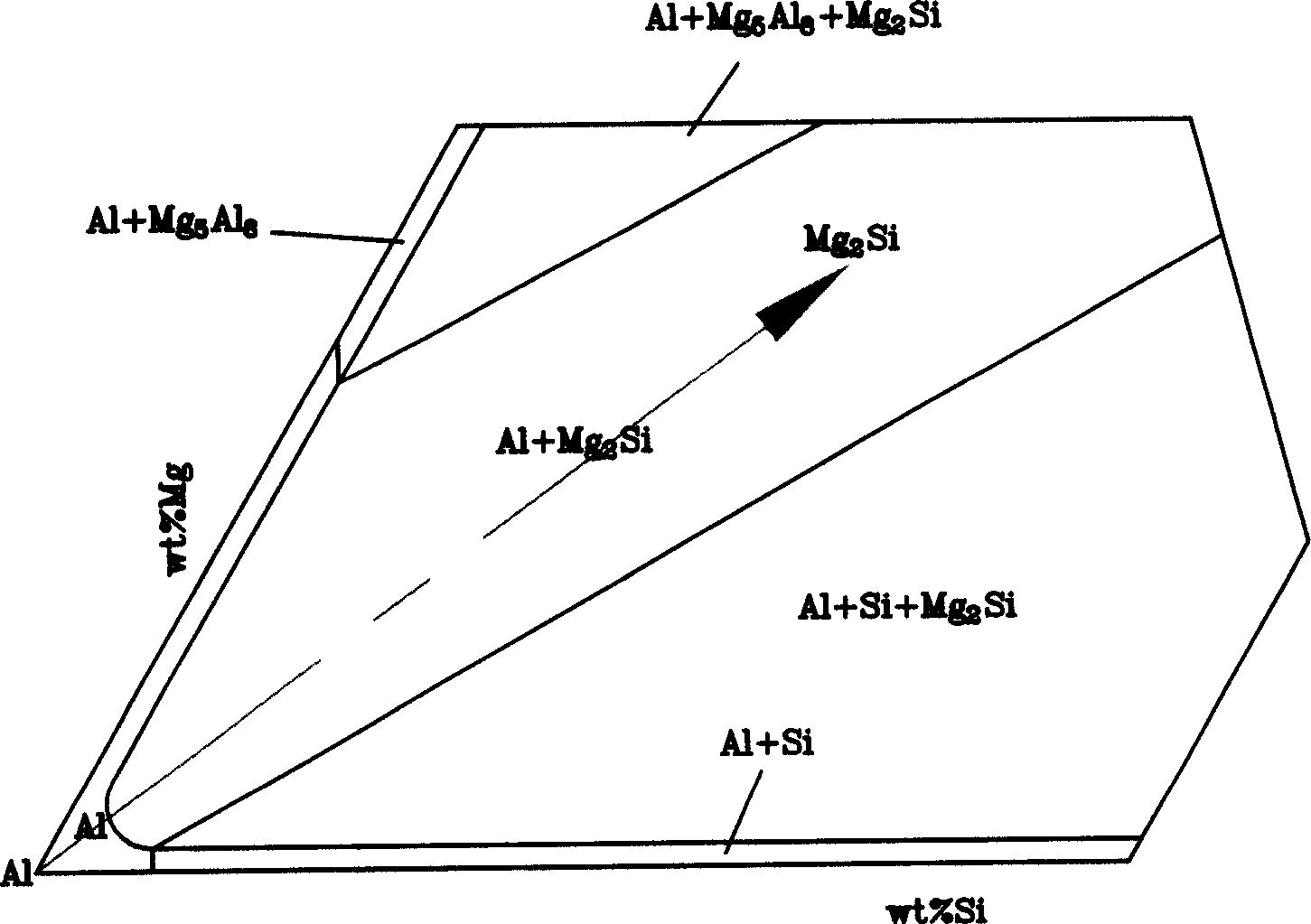

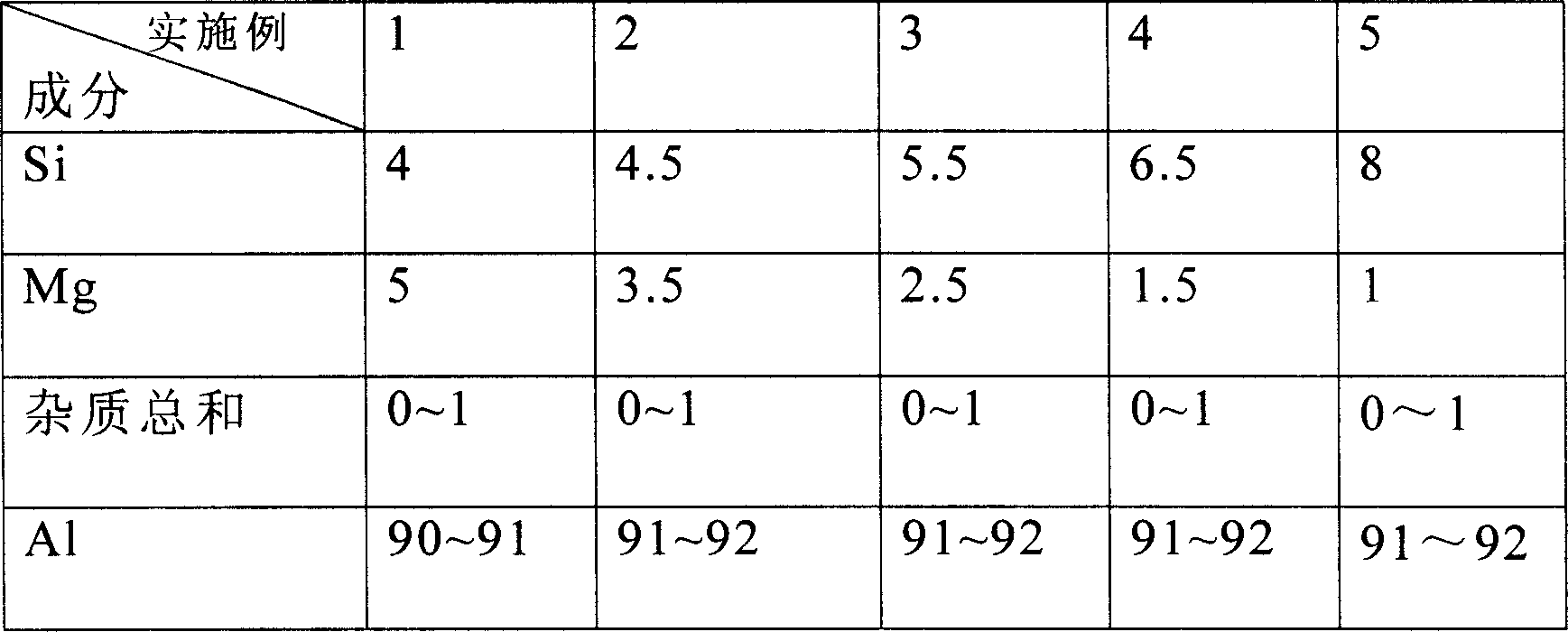

Pressure cast aluminium alloy and its application

The present invention provides one kind of pressure cast aluminum alloy and its application, and belongs to the field of material science. The pressure cast aluminum alloy consists of Si 4-8 wt%, Mg 1-5 wt%, and Al for the rest. The pressure cast aluminum alloy is applied to produce hard anodized oxide film through the following steps: smelting, pressure casting, modifying mechanically, and forming hard anodized oxide film. The pressure cast aluminum alloy has anodized oxide film with great thickness, high hardness and high corrosion resistance.

Owner:ZHEJIANG SUPOR CO LTD

Scandium and strontium compound microalloyed high zinc 2099 type aluminium alloy and preparation method thereof

The invention discloses a scandium and strontium compound microalloyed high zinc 2099 type aluminium alloy and preparation method thereof. The aluminium alloy is mainly composed of the following elements by mass percent: 2.3-2.57% of copper (Cu), 1.86-1.96% of lithium (Li), 1.14-1.31% of zinc (Zn), 0.269-0.420% of magnesium (Mg), 0.219-0.321% of manganese (Mn), 0.0733-0.08% of zirconium (Zr), 0.0643-0.0943% of strontium (Sr) and 0.0433-0.079% of scandium (Sc), the balance is aluminium (Al) and less impurity elements. The preparation method of the alloy adopts the manufacturing method of intermediate alloy. The invention has simple method, the prepared alloy has low density, high rigidity and good corrosion resistance, and the invention can meet the requirement of the national aviation and weaponry fields to high performance aluminium alloy.

Owner:JIANGSU UNIV

2xxx aluminium alloy for aviation and processing method thereof

The invention relates to a 2xxx aluminium alloy for aviation and a processing method thereof; in the alloy, Mg is 1.3-1.5wt%, Cu is 3.5-4.05wt%, Si is less than or equal to 0.10wt%, Fe is less than or equal to 0.10wt%, Mn is 0.5-0.7wt%, Cr is less than or equal to 0.10wt%, Ti is less than or equal to 0.15wt%, Zr is 0.10-0.15wt%, and Al is the balance; the ratio between Cu and Mg is 2.50-2.70:1.The processing technology is as follows: carrying out homogenized annealing on alloy ingot, namely heating the alloy ingot from room temperature to 490-500 DEG C with the heating rate of 40-50 DEG C / h, preserving heat for 10-30h, then air cooling; carrying out extruding at the temperature of 400-490 DEG C after the homogenized annealing of the alloy ingot to obtain alloy sheet; naturally placing the extruded alloy sheet for above 100h after solutionizing for 495 DEG C / h. The technical proposal of the invention controls the contents of surplus phases in the structure by reasonably adjusting the contents of Cu and Mg in the 2xxx aluminium alloy, and ensures the content of main reinforced phase Al2CuMg, thus providing the materials with better strength and plasticity; scientific technical measures ensure the materials to be provided with better comprehensive mechanical property, thus being the ideal materials for manufacturing aviation parts.

Owner:苏州有色金属研究院有限公司

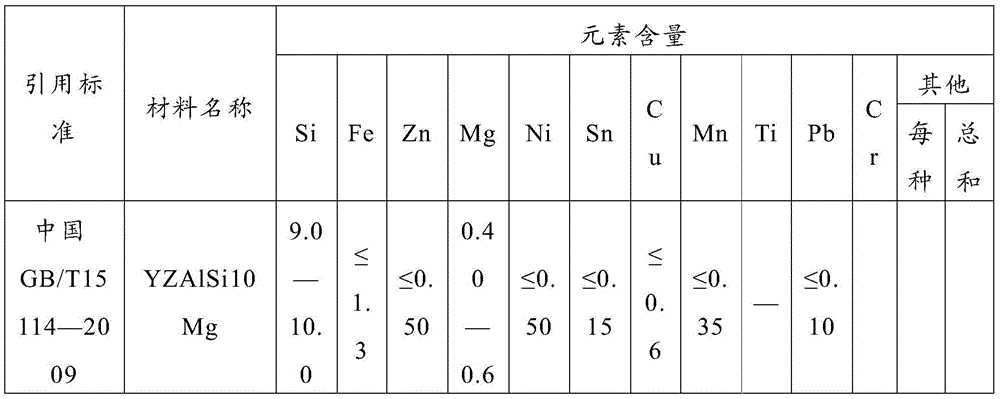

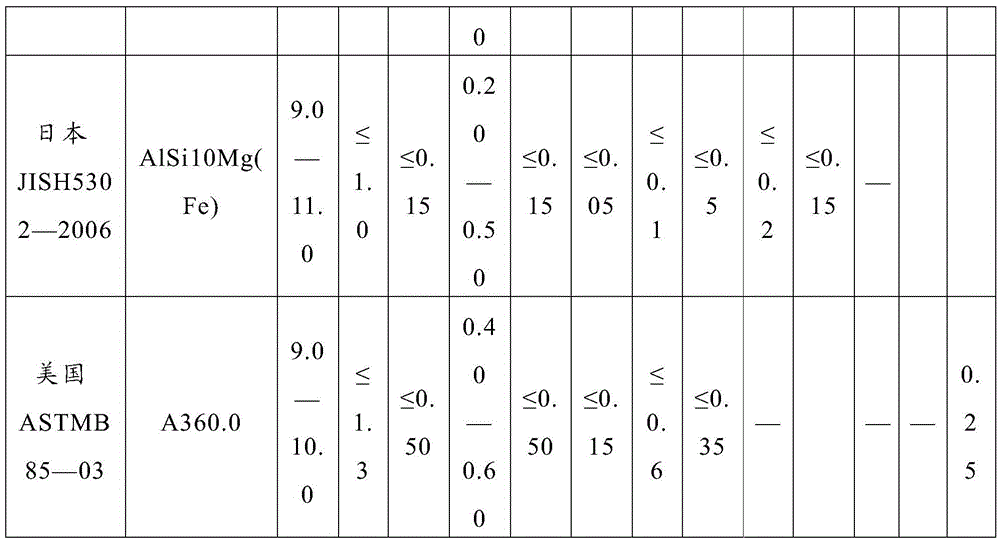

Al-Si-Mg cast aluminium alloy for pressure casting, and preparation method thereof

ActiveCN105483465AImprove mechanical propertiesGood welding performancePressure casting5005 aluminium alloy

The invention provides an Al-Si-Mg cast aluminium alloy for pressure casting and a preparation method thereof. The Al-Si-Mg cast aluminium alloy for pressure casting comprises the following components according to mass fraction: Si, Mg, Mn, Ti, B, Sb, Re, Fe, V, C, r, Zr, P, Be and the balance of Al. The Al-Si-Mg cast aluminium alloy for pressure casting has high-strength and high-toughness mechanical properties, and the mechanical property of a pressure casting test bar can reach the followings: casting state tensile strength (Sigma): 230-310 MPa, the yield strength (Sigma<0.2>): 115 to 160 MPa, and the percentage of elongation (Delta): 5.5 to 14.5. The Al-Si-Mg cast aluminium alloy for pressure casting has an excellent comprehensive mechanical property, particularly an elongation percentage, which is 1.5 times of the maximum value 3.5 percent stipulated in all material standards. Further, the Al-Si-Mg cast aluminium alloy is also excellent in welding performance and suitable for combined welding of castings.

Owner:NONFERROUS METALLIC OF HEBEI NEW LIZHONG GRP CO LTD

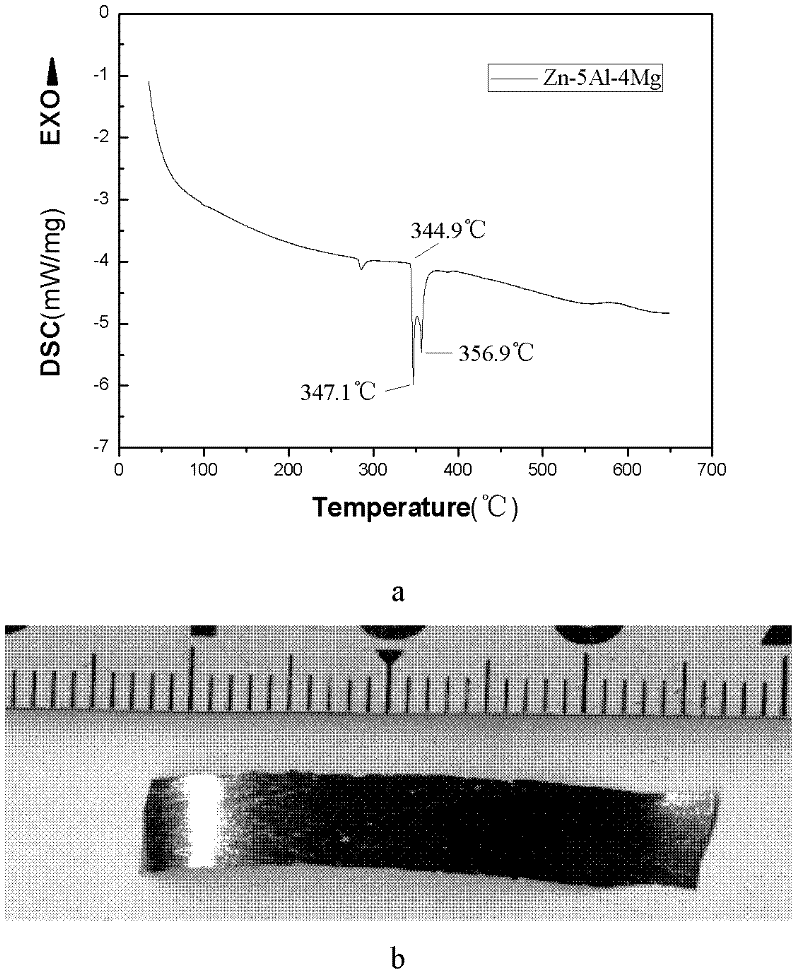

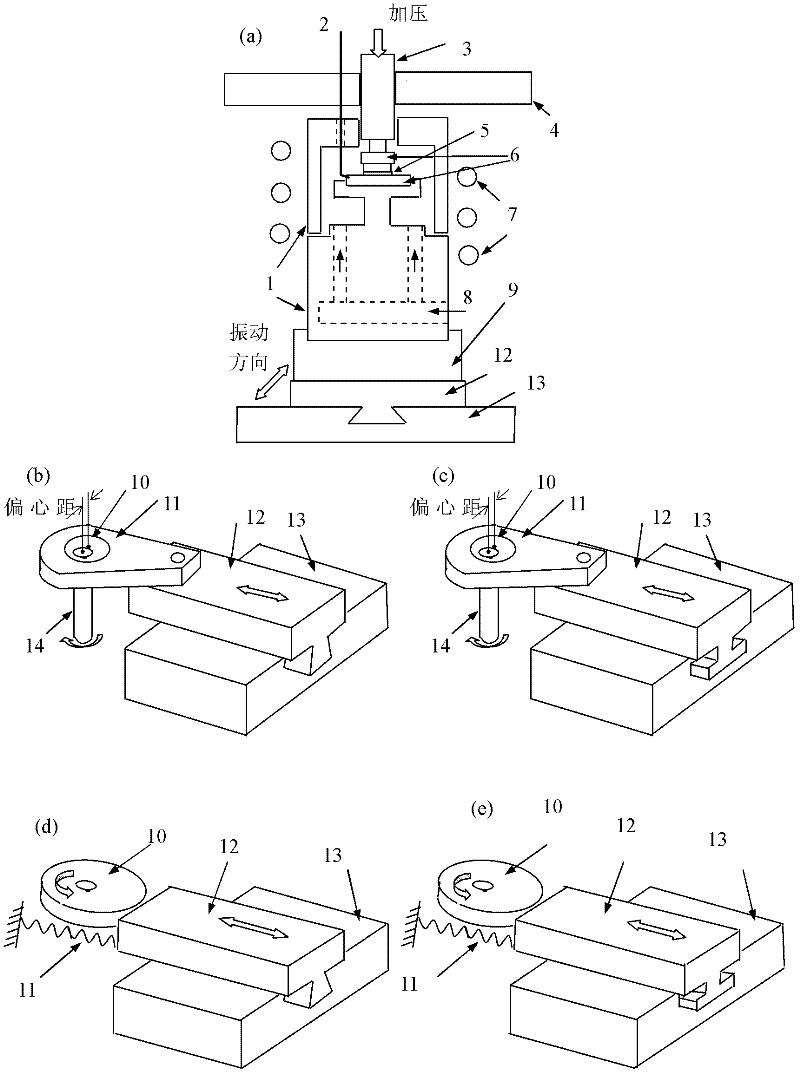

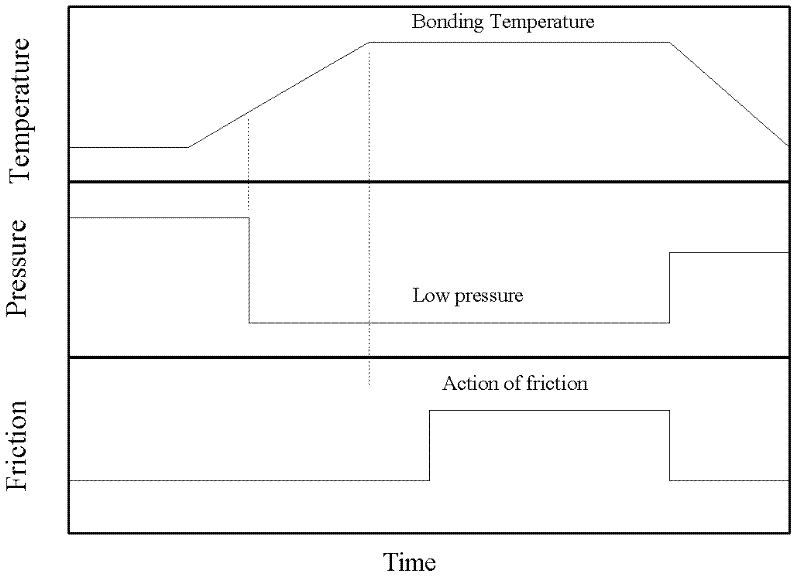

Aluminium matrix composite, brazing filler metal for aluminium alloy and brazing method

InactiveCN102632347ALow costEasy to makeWelding/cutting media/materialsSoldering mediaShielding gas5005 aluminium alloy

In order to improve the defect that the interface of a Zn-Al brazing filler metal and an Al matrix has no reaction or the reaction is not uniform (limited to a corrosion section and part crystal boundary), the invention discloses an aluminium matrix composite, a low-melting-point Zn-Al-Mg ternary active brazing filler metal (comprising 3-10% of Al, 2-7% of Mg and the balance of Zn, wherein the corresponding melting range is 337-475 DEG C) and a low-frequency low-amplitude reciprocating friction assistant low-temperature active soft brazing method. The low-temperature active soft brazing method is used as the other auxiliary method under the low-temperature working condition, when the low-frequency low-amplitude friction is applied, and the improvements on the liquid-phase liquidity, the striping effect and the wetting property are more notable. The low-frequency low-amplitude friction assistant low-temperature active soft brazing method comprises the following steps of: presetting brazing filler metal, then pressurizing and heating, canceling the pressure until the temperature is 330 DEG C, sequentially heating until the temperature is 400-550 DEG C, performing heat preservation and leading in the low-frequency low-amplitude friction. According to the method, a soldering flux is not needed, the brazing filler metal prematurity loss is avoided, and no obvious corrosion and / or ceramic grain prejudiced collection is caused; and the brazing filler metal uniformly infiltrate, the diffusion required time is shortened, and protected gas is not essential.

Owner:XI AN JIAOTONG UNIV

Aluminium alloy material, aluminium alloy shaped part, and preparation method of aluminium alloy shaped part

ActiveCN105695809AHigh thermal conductivityGood molding effectTelephone set constructions5005 aluminium alloyMechanical property

The invention provides an aluminium alloy material. The aluminium alloy material is composed of, by mass, 5.5 to 8.5% of silicon, 0.1 to 0.4% of magnesium, 0.01 to 0.2% of boron, chromium<0.05%, 0.05 to 0.5% of iron, strontium<0.1%, and aluminium and inevitable impurities, wherein the content of each impurity element is less than 0.05%. The aluminium alloy possesses high heat-conducting properties, and excellent forming properties, and mechanical properties; thermal conductivity is higher than 140W / m.k under common pressure casting conditions; thermal conductivity is even higher than 150W / m.k under gravity casting or extrusion casting conditions; the aluminium alloy can be applied to the field of mobile phone product and communication product, can be used for solving problems in the prior art that thermal conductivity properties of materials used in mobile phone products and communication products are poor, product heat dissipation performance is poor, and severe heating phenomenon is caused. The invention also provides an aluminium alloy shaped part prepared from the aluminium alloy, and a preparation method of the aluminium alloy shaped part.

Owner:HUAWEI TECH CO LTD +1

High strength easy-to-cut aluminum alloy

ActiveCN101307403AExcellent machinabilityImprove mechanical properties5005 aluminium alloyMechanical property

The invention relates to a high-strength easy-cutting aluminium alloy. The invention is characterized in that the aluminium alloy is an aluminium-base alloy, containing bismuth, tin, copper, silicon and chromium as alloying elements, and other unavoidable impurity elements. A product produced by the alloy has good easy-cutting capability, excellent mechanical property, excellent corrosion resistance and excellent solderability. The aluminium alloy has low production cost and is equivalent to the prior leady aluminium alloy, so the aluminium has competitive advantages in domestic and foreign markets; The aluminium alloy product can replace partial leady aluminium alloys, thereby not only facilitating the reclamation when the product is consumed completely so as to reduce lead pollution, but also facilitating the expansion of the application field of aluminium alloy products. The aluminium alloy also can replace partial leady easy-cutting aluminium alloys, such as 2011 or 6262 leady aluminium alloy and so on.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Al-Fe-Cr-RE aluminium alloy, preparation method thereof and power cable

ActiveCN103103388AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cable5005 aluminium alloy

The invention provides an Al-Fe-Cr-RE aluminium alloy and a preparation method thereof. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

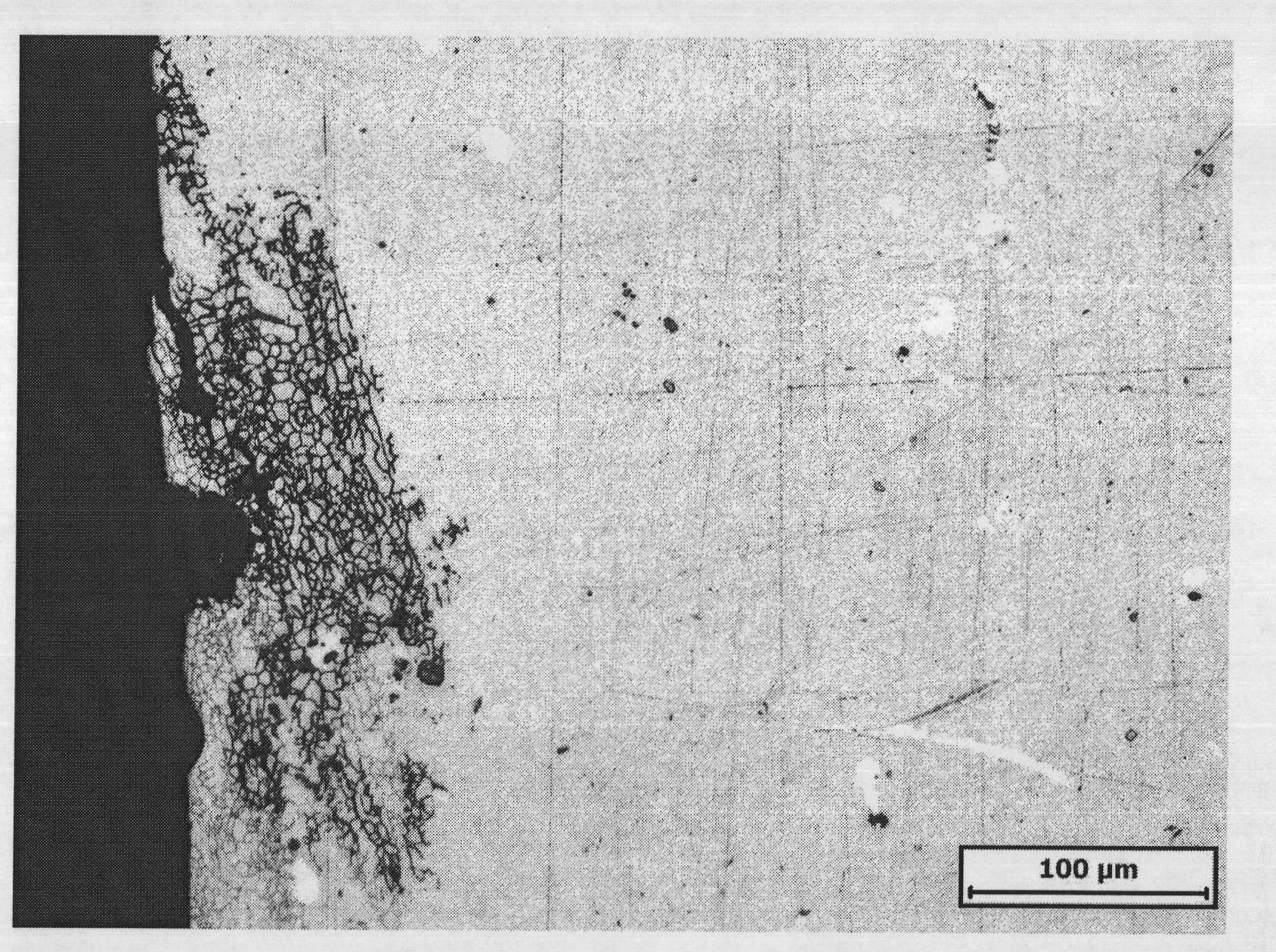

Aluminium alloys brazing sheet for thin tubes

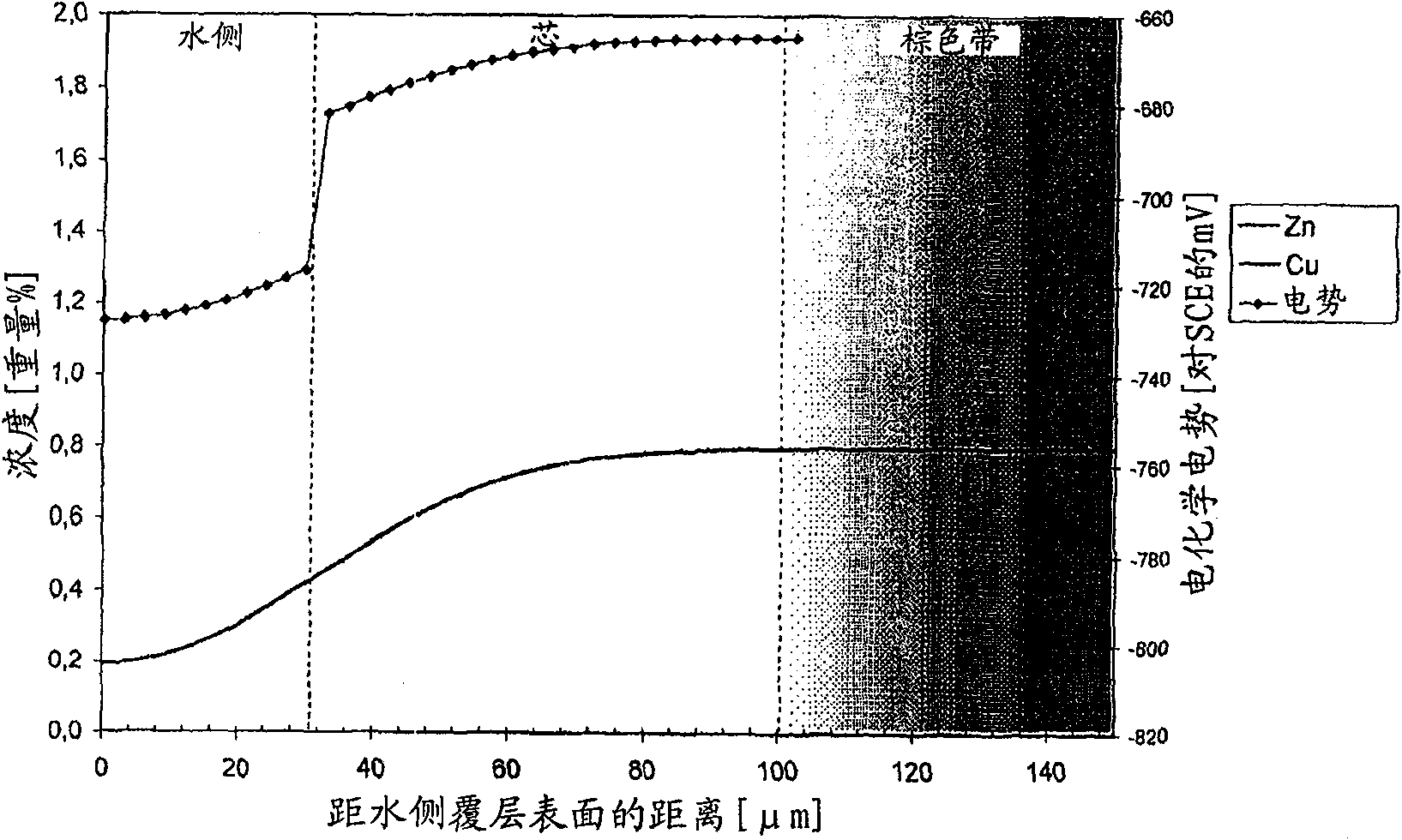

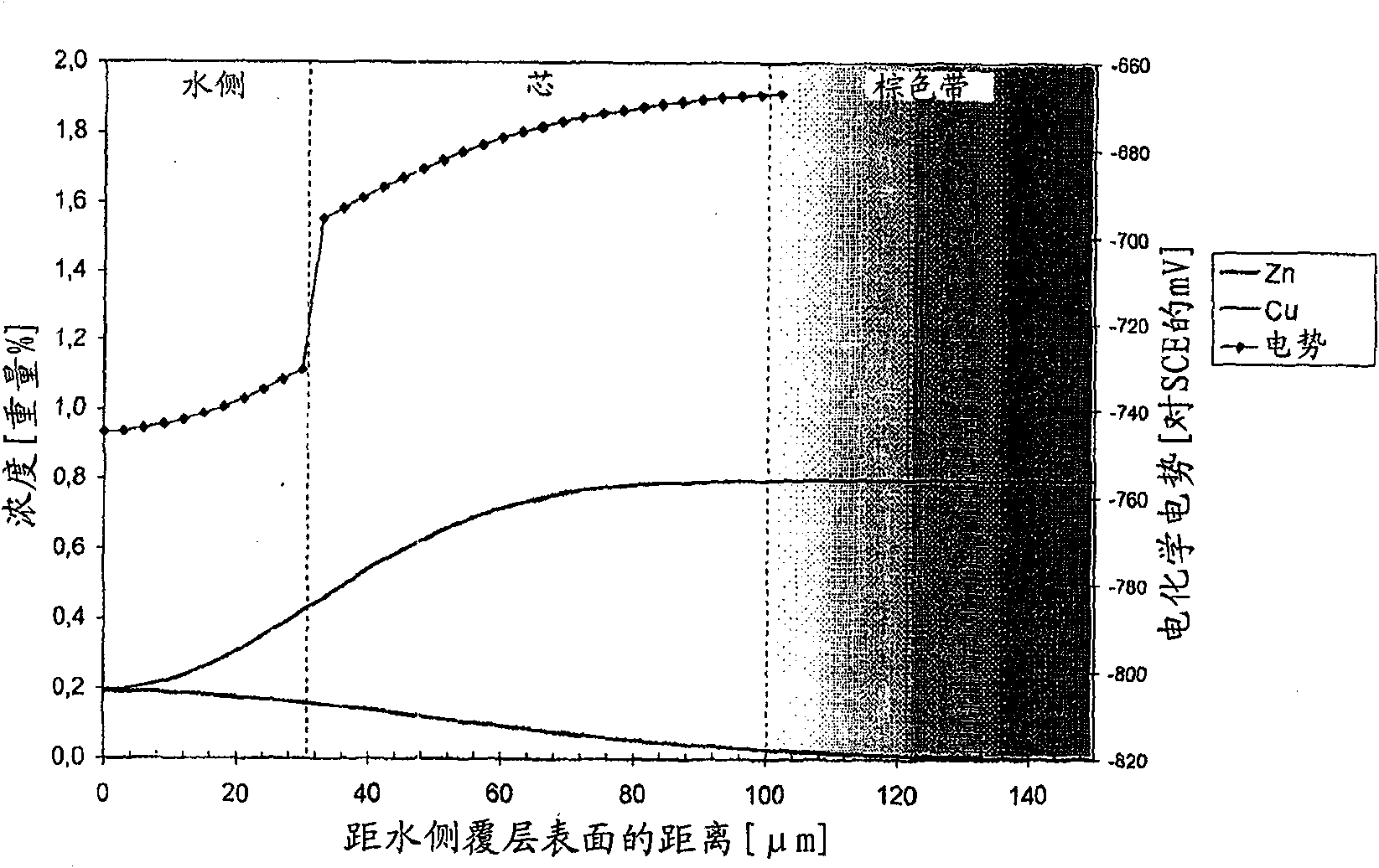

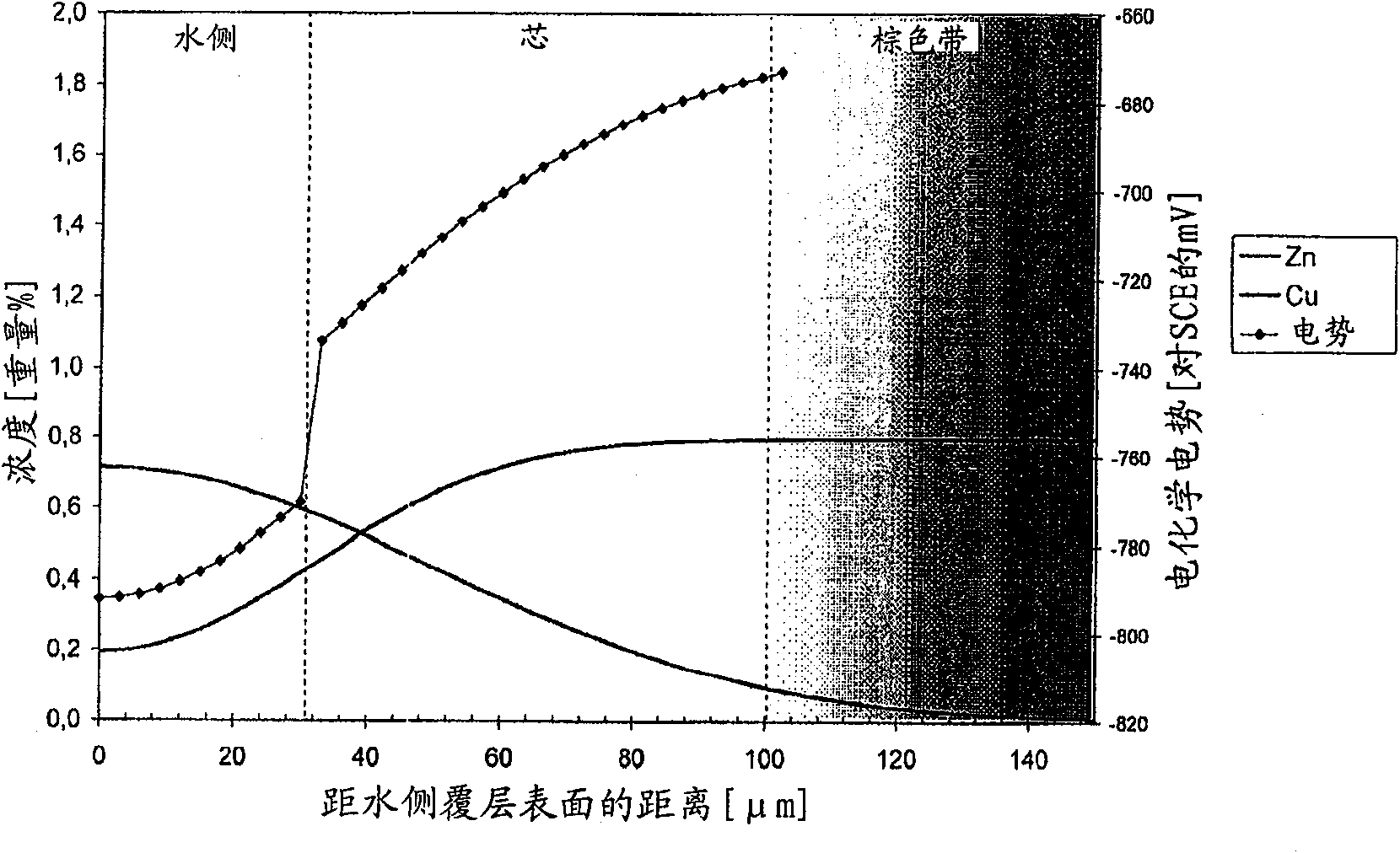

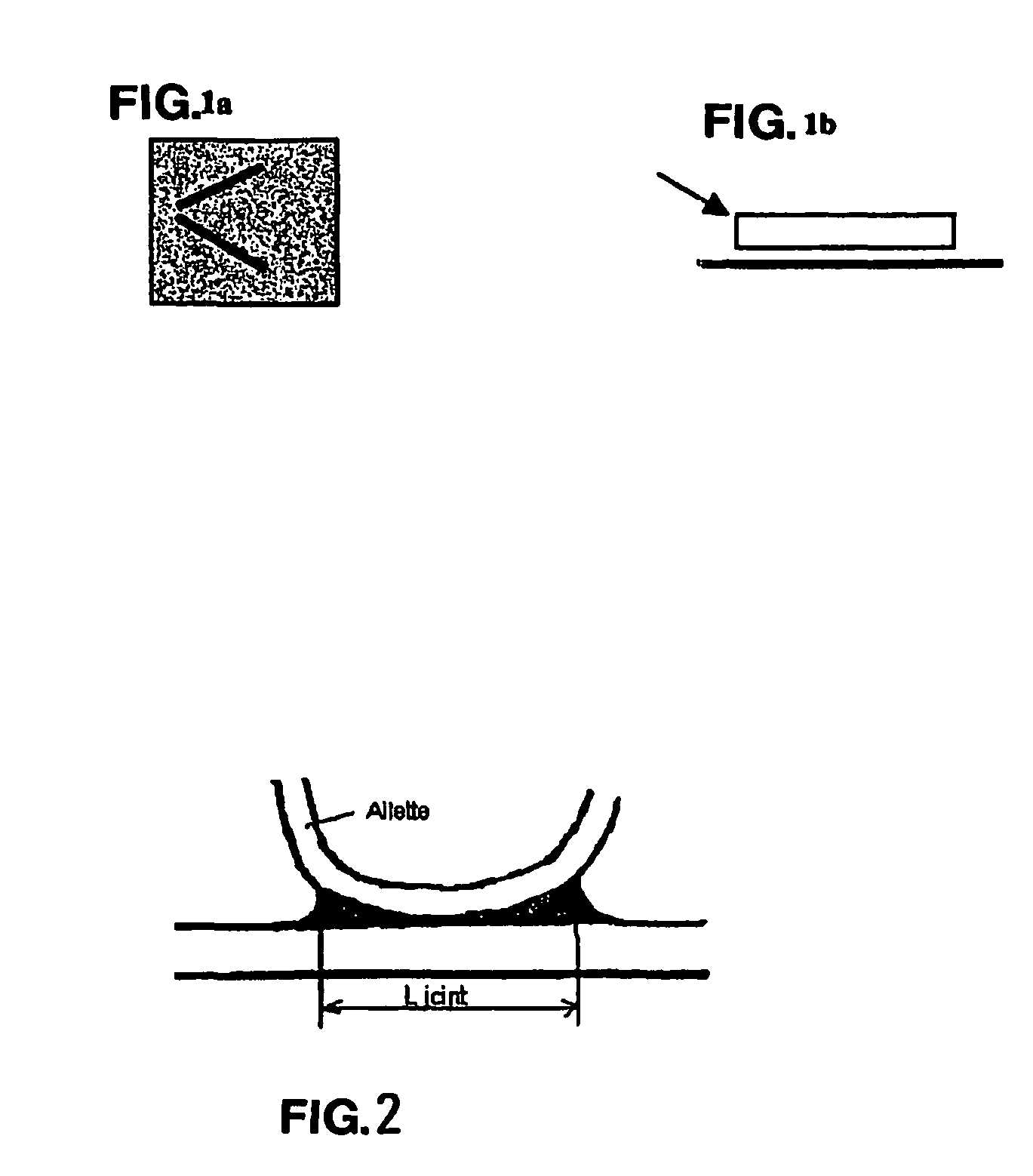

InactiveCN101886195ALower potentialWelding/cutting media/materialsCoatingsImpurity6005 aluminium alloy

An aluminium alloy brazing sheet comprising: a core material made of an aluminium alloy consisting of <=0.1 wt% Si, most preferably <= 0.06wt% Si, <= 0.35 wt% Mg, from 1.0 to 2.0 wt%, preferably 1.4 to 1.8 wt% Mn, from 0.2 to1.0, preferably 0.6 to 1.0 wt% Cu, <=0.7 wt% Fe, <=0.3 wt% each of Zr, Ti, Ni, Hf, V, Cr, In, Sn and <=0.5 wt% total of Zr, Ti, Ni, Hf, V, Cr, In, Sn, the remainder being Al and unavoidable impurities; and a waterside cladding material clad on at least one side of the core material, said cladding material being made of an aluminium alloy having a potential lower than that of said core material and consisting essentially of 0.5-1.5 wt% of Si, 1.0 to 2.0 wt% preferably 1.4-1.8 wt% of Mn, <=0.15 wt% Mg, <= 0.1% Cu, <= 0.7 wt% Fe, <=1.4 wt%, preferably <= 1.1 wt%, most preferably <=0.4 wt% Zn, <=0.3 wt% each of Zr, Ti, Ni, Hf, V, Cr, In, Sn and <=0.5 wt% total of Zr, Ti, Ni, Hf, V, Cr, In, Sn, the remainder being Al and unavoidable impurities, wherein the ratio of wt% Si in the waterside clad to wt% Si in the core is at least 5:1, preferably at least 10:1.

Owner:SAPA HEAT TRANSFER AB

6410 aluminium alloy and preparation method and application of 6410 aluminium alloy

ActiveCN102676892AMelting process optimizationDefect suppression or elimination5005 aluminium alloyBULK ACTIVE INGREDIENT

Disclosed is a 6410 aluminium alloy for bright anodic oxidation. The 6410 aluminium alloy is prepared by smelting 99.99wt. % of high purity refined aluminum, silicon (Si), copper (Cu), magnesium (Mg), titanium (Ti) and carbon (C), wherein by weight, the Si is 0.35wt. %-0.55wt. %, the Cu is 0.08wt. %-0.14wt. %, the Mg is 0.35wt. %-0.70wt. %, the Ti is 0.006wt. %-0.012wt. %, and a trace of the C is equivalent to one twentieth of the content of the Ti; and ferrum (Fe) is equal to or smaller than 0.04wt. %, other impurities are equal to or smaller than 0.01wt. %, the balance is aluminum, the Si, the Cu, the Mg and the Ti are active ingredients, the Fe is a main impurity element, and the weight of the Fe is required to be limited. The preparation method of the 6410 aluminium alloy includes that high purity refined aluminum ingots are subjected to heating and smelting to obtain an aluminum liquid, the Si, the Cu and the Mg are added, flow quantity of the aluminum liquid is set when the aluminum liquid flows through a runner, the aluminum liquid is led to a casting furnace, the Ti and the C are continuously added into the aluminum liquid runner according to the requirement, the aluminum liquid is subjected to refining and filtering by means of on-line argon, and standard aluminum bars are obtained after hot-top casting. The 6410 aluminum alloy can be used for manufacturing bright anodic oxidation automobile exterior trimming parts.

Owner:JIANGSU HEXING AUTOMOTIVE TECH

A liquid die forging aluminium alloy and a preparing method thereof

A liquid die forging aluminium alloy and a preparing method thereof are disclosed. Raw materials of the aluminum alloy include 45-50% by mass of waste automobile aluminum wheels, 25-30% by mass of waste automobile aluminum gearbox shells, 10-12% by mass of waste aluminum pop cans and 5-8% by mass of waste aluminum electric wires and cables, with the balance being aluminium ingots. Waste aluminum is adopted as the main raw material. The liquid die forging aluminium alloy having high performance is directly regenerated through optimizing composition of the waste aluminum raw materials, thus increasing the using value of the waste aluminum and reducing the production cost of the liquid die forging aluminium alloy. The produced liquid die forging aluminium alloy has advantages of high strength and good plasticity, can be used as load-bearing structure parts of automobiles, electronic products, mechanical equipment, aviation and spaceflight, weapon equipment, and the like, and has a wide application prospect.

Owner:广州金邦液态模锻技术有限公司

Aluminium alloy casting manufacturing process

InactiveCN102605206AStable temperatureStable casting temperatureAbrasive blasting5005 aluminium alloy

The invention provides an aluminium alloy casting manufacturing process, which has high working efficiency, high product percent of pass and good casting mechanical property. The aluminium alloy casting manufacturing process is characterized by comprising the following steps: melting, insulation, casting, finishing, thermal treatment and abrasive blasting. Dry nitrogen is blown into aluminium alloy liquid by a carbon rod, the nitrogen directly enters the aluminium alloy liquid so as to be capable of better taking away gas of the aluminium alloy liquid and removing the gaseous impurities in the aluminium alloy liquid and reducing the possibility that castings manufactured have air holes; and a holding furnace can control the temperature of the alloy liquid to maintain stable, thus further leading the temperature of the alloy liquid to maintain stable, avoiding the defects that the castings have air holes and sink holes, can not be insufficiently cast, or are unclear in outline, and the like, and improving the product percent of pass.

Owner:TIANJIN QIANXIN NONFERROUS METAL PRODS

Aluminium alloy plate, making method and aluminium alloy made cell box

The aluminum alloy sheet is composed of aluminum alloy containing, by mass%, 0.9-1.5% Mn, >0.50-1.0% Cu, 0.2-0.6% Mg, 0.05-0.50% Si, 0.05-0.60% Fe, Zn regulated to <=0.10% and the balance Al with inevitable impurities. In this manner, this invention provides an aluminum alloy sheet for a battery case which is excellent in strength, formability, laser weldability, stress relaxation property and pressure resistance (bulging resistance) even when the sheet thickness is reduced, and to provide a production method therefor.

Owner:KOBE STEEL LTD

Preparation method of high-strength die casting aluminium alloy

The invention discloses a preparation method of a high-strength die casting aluminium alloy, relating to the technical field of aluminium alloy preparation. The method comprises the following steps: heating all the components of the alloy to 110-130 DEG C, then melting aluminium at 740-760 DEG C to obtain molten aluminium and then maintaining the temperature for 6-10 minutes; adding Si and Mn to molten aluminium, melting Si and Mn in sequence, then reducing the temperature to 650-660 DEG C and pressing Mg in the alloy liquid entirely; raising the temperature to 720-750 DEG C, removing dross, then adding the remaining alloy components to the alloy liquid in sequence, maintaining the temperature for 20-30 minutes, then raising the temperature to 770-780 DEG C to carry out refining, maintaining the temperature for 10-15 minutes and removing the dross; cooling an obtained melt to 660-680 DEG C and then pressing the melt in a die preheated to 180-220 DEG C to undergo die casting. The problems that the existing die casting aluminium alloys have lower strength and elongation are solved by adopting the preparation method.

Owner:LIUZHOU BAITIAN MACHINERY

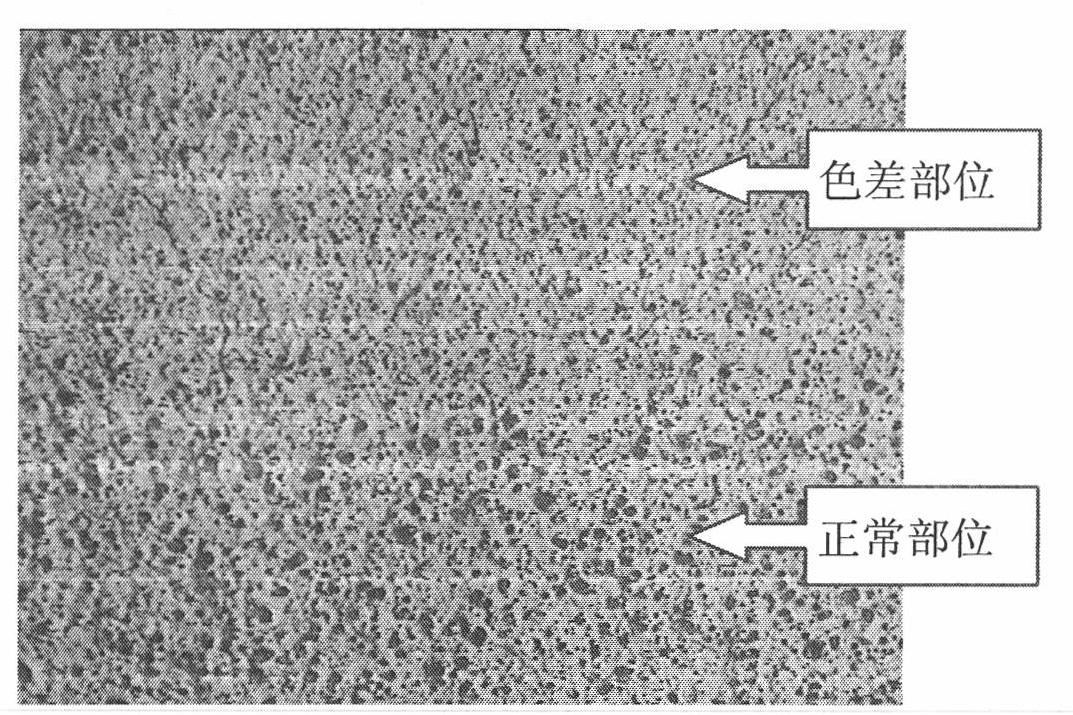

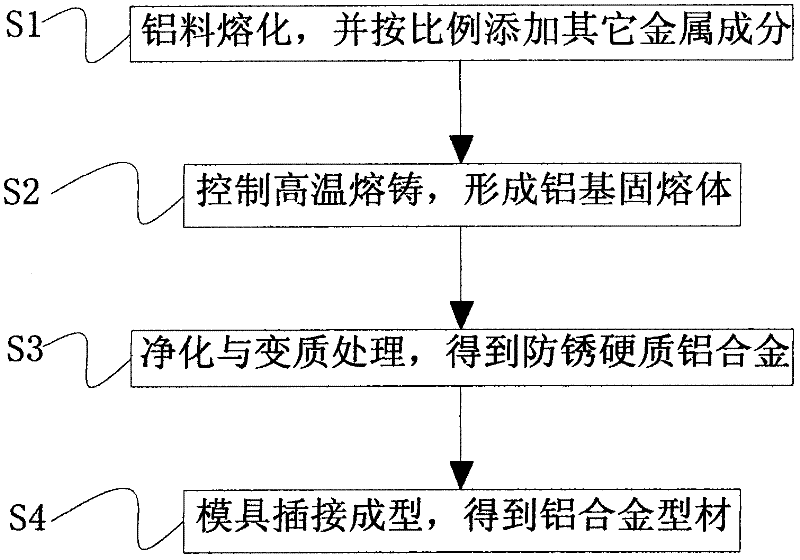

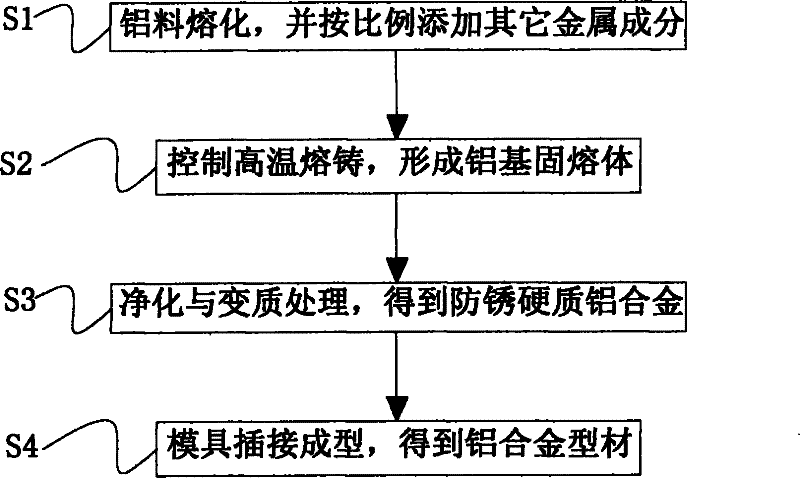

Aluminium alloy section and manufacture method thereof

InactiveCN102127667AGood corrosion resistanceHigh mechanical strengthAnodisation5005 aluminium alloy5052 aluminium alloy

The invention discloses an aluminium alloy section and a manufacture method thereof. The aluminium alloy section comprises the following elementary components of 87.5 percent of Al, 0.4 percent of Si, 1.1 percent of Fe, 0.75 percent of Mn, 0.8 percent of Mg, 2.1 percent of Zn, 4.4 percent of Cu, 0.1 percent of Ni and 0.1 percent of Ti. The manufacture method of the aluminium alloy section comprises the following process steps of: (1) melting an aluminium material, and adding metal components including the Si, the Fe, the Cu, the Mn, the Mg, the Zn, the Ni and the Ti; (2) controlling high temperature for casting to form an aluminium-based solid solution; (3) carrying out purification treatment and modification to enable grains to be refined and reduced to 1 / 20 before treatment and enable the total content to be reduced by 30 percent to obtain antirust hard aluminium alloy; and (4) splicing and molding by adopting a mould to obtain the aluminium alloy section. The aluminium alloy section provided by the invention has favorable corrosion resistance and excellent mechanical strength and is superior to a general section for a common laboratory.

Owner:湖南朗圣实验室技术股份有限公司

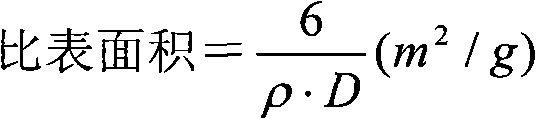

Hot dip coating cast aluminium alloy and preparation method thereof

ActiveCN101899598ASufficient resistance to electrochemical corrosionRapid self-healing damage5005 aluminium alloyDip-coating

The invention relates to a hot dip coating cast aluminium alloy used for antiseptic treatment of various marine climate-resistant engineering components and a preparation method thereof, wherein the cast aluminium alloy is composed of metal of Al, Zn, Si and the like, nanometer oxide particle intensifier and unavoidable impurities; and the nano oxide particle intensifier is selected from one or two of TiO2 and CeO2. The cast aluminium alloy prepared by the invention can be used as a coating which enables the engineering components to have full decay resistance and scour corrosion resistance.

Owner:JIANGSU LINLONG NEW MATERIALS

Method for brazing strips of aluminium alloy

The invention relates to an aluminum alloy strip or sheet with the following composition (% by weight):Si 0.3-1.0; Fe<1.0; Cu 0.3-1.0; Mn 0.3-2.0; Mg 0.3-3.0; Zn<6.0; Ti<0.1; Zr<0.3; Cr<0.3; Ni<2.0; Co<2.0; Bi<0.5; Y<0.5, other elements <0.05 each and 0.15 total, the remainder being aluminum,coated on at least one face with an aluminum brazing alloy containing 4 to 15% of silicon and 0.01 to 0.5% of at least one of the Ag, Be, Bi, Ce, La, Pb, Pd, Sb, Y elements or mischmetal. Sheets and strips according to the invention can be used particularly for fluxless brazing of heat exchangers.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD +1

6063 aluminium alloy made by fine grained aluminium ingot and preparation method thereof

This invention provides a 6063 aluminum alloy made by cryptomere aluminium ingot. It is constituted by Al, Si, Mg, RE, B elements, quality portion is that Si 0.20~0.6%, Mg 0.45~0.9%, REíœ0.35%, Bíœ0.01%. It also provides a method of preparing the 6063 aluminum alloy, aluminum oxide and titanium oxide compound is added into aluminum electrolyte tank, cryptomere aluminium ingot with titanium quality portion is 0.01~0.20% is generated, alloy element is added to cryptomere aluminium ingot directly from electrolyte tank or by cryptomere aluminium ingot melting to melted 6063 aluminum alloy. Because of its special titanium adding mode, production cost is cheap, as-cast grain is little and uniform, its tensile strength is equal to 6063 aluminum alloy thinned by aluminium titanium boron hardner, and extensibility is increased 20% and better surface capability can get. 6063 aluminum alloy after pressure has good ageing characteristic, it can reach high intension in short time and keep high intension long time, it is hard overaging.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com