Al-Fe-Rh-RE aluminium alloy, preparation method thereof and power cable

A power cable and aluminum alloy technology, applied in the field of alloys, can solve problems affecting the service life of aluminum alloy materials, poor comprehensive performance of aluminum alloy power cables, and quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides a method for preparing an Al-Fe-Rh-RE aluminum alloy, comprising the following steps:

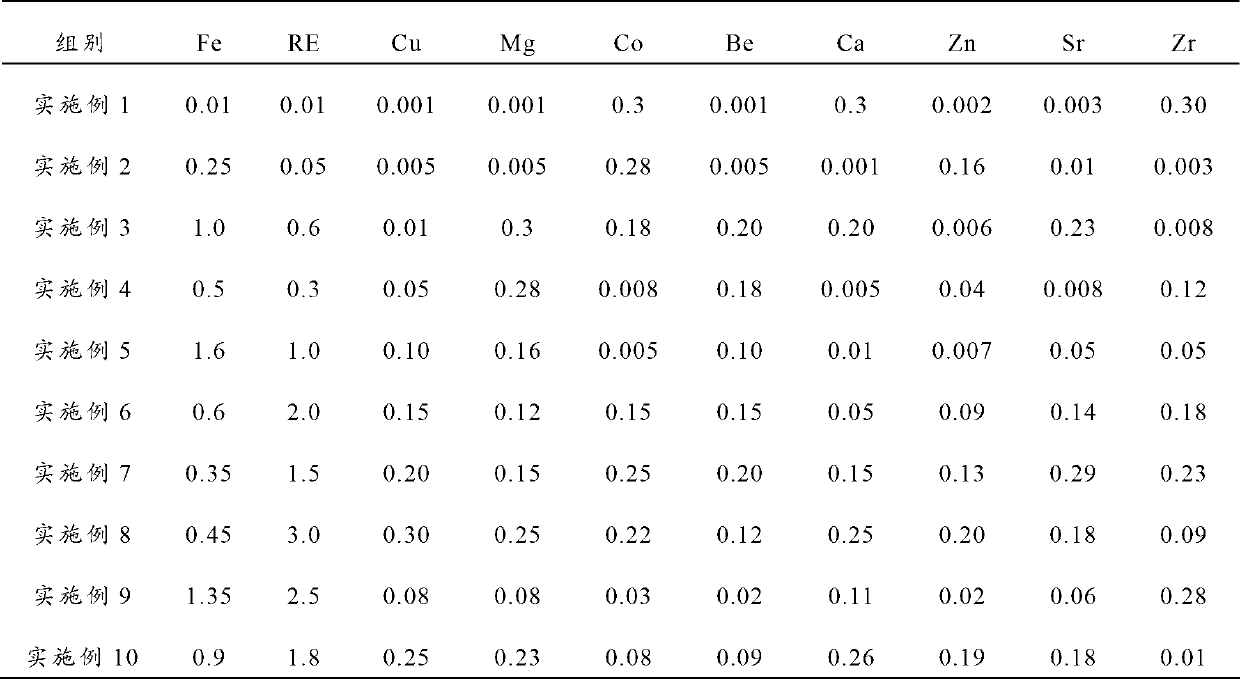

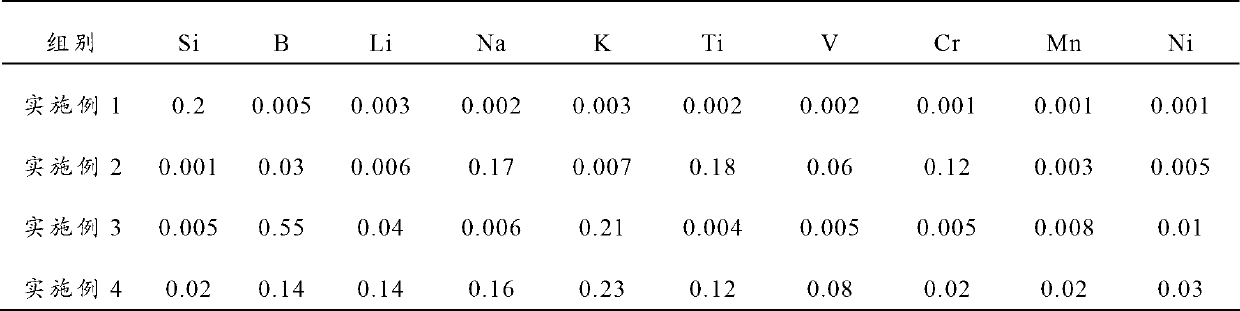

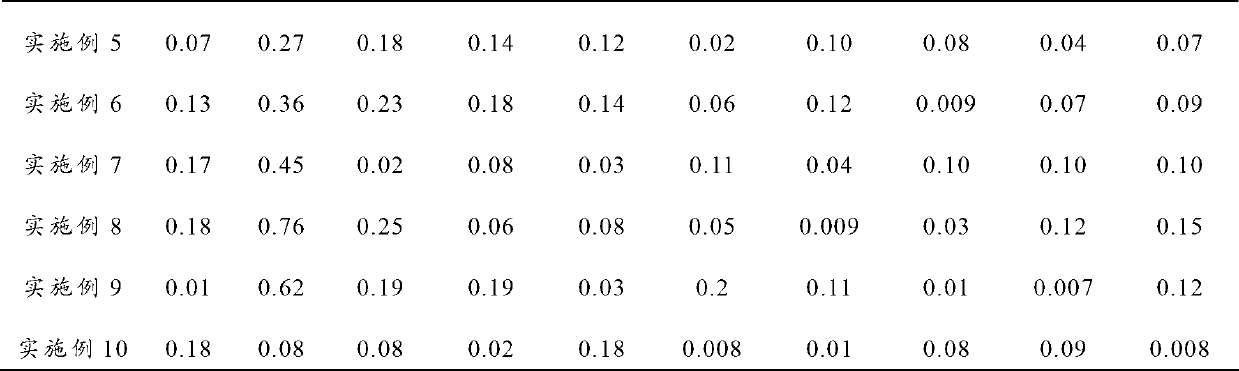

[0059] a) Cast the raw materials of the following composition to obtain an aluminum alloy ingot: 0.01~1.6wt% Fe, 0.001~0.3wt% Cu, 0.001~0.3wt% Mg, 0.001~0.3wt% Co, 0.001~0.2 wt% Be, 0.001~0.3wt% Ca, 0.001~0.2wt% Zn, 0.001~0.3wt% Sr, 0.001~0.3wt% Zr, 0.002~0.25wt% Li, 0.001~0.2wt% Na, 0.002~0.25wt% K, 0.001~0.2wt% Ti, 0.001~0.15wt% V, 0.001~0.12wt% Cr, 0.001~0.12wt% Mn, 0.001~0.15wt% Ni , 0.001~0.2wt% of Ga, 0.003~0.2wt% of Ge, 0.001~0.2wt% of Rb, 0.001~0.15wt% of Nb, 0.001~0.2wt% of Mo, 0.001~0.25wt% of Tc, 0.001 ~0.15wt% of Ru, 0.002~0.1wt% of Rh, 0.01~3.0wt% of RE, greater than zero and less than or equal to 0.2wt% of Si, greater than zero and less than or equal to 0.8wt% of B and the balance of aluminum;

[0060] b) performing homogenization treatment on the aluminum alloy ingot, and rolling the homogenized aluminum alloy ingot to obtain an al...

Embodiment 1

[0072](1) Put the aluminum ingot into the furnace, heat it to melt and keep it warm at 720°C. The melting process is completed in a sealed environment; first add Fe, Cu, Mg, Co, Be, Ca, Zn, Sr, Zr, Si , B, Li, Na, K, Ti, V, Cr, Mn, Ni, Ga, Ge, Rb, Nb, Mo, Tc, Ru and Rh pure metals, stir well and then add rare earth RE and stir for 20min until fully stirred evenly , put it aside for 30 minutes; then refine the above alloy melt in the furnace; add refining agent to the alloy melt, stir evenly, then let it stand for 30 minutes, and operate the melt refining in a sealed environment; after refining, slag, Stand still, adjust the temperature to 650°C, pour the alloy liquid out of the furnace, and after degassing and slag removal, enter the casting machine for casting to obtain aluminum alloy ingots. The composition of the ingots is listed in Table 1;

[0073] (2) Heat up the aluminum alloy ingot obtained in step (1) at a rate of 5°C / min to 450°C, hold it for 6 hours, and then roll i...

Embodiment 2

[0078] (1) Put the aluminum ingot into the furnace, heat it to melt and keep it warm at 740°C. The melting process is completed in a sealed environment; first add Fe, Cu, Mg, Co, Be, Ca, Zn, Sr, Zr, Si , B, Li, Na, K, Ti, V, Cr, Mn, Ni, Ga, Ge, Rb, Nb, Mo, Tc, Ru and Rh pure metals, stir well and then add rare earth RE and stir for 20min until fully stirred evenly , put it aside for 30 minutes; then refine the above alloy melt in the furnace; add refining agent to the alloy melt, stir evenly, then let it stand for 30 minutes, and operate the melt refining in a sealed environment; after refining, slag, Stand still, adjust the temperature to 720°C, pour the alloy liquid out of the furnace, and after degassing and slag removal, enter the casting machine for casting to obtain aluminum alloy ingots. The composition of the ingots is listed in Table 1;

[0079] (2) Heat up the aluminum alloy ingot obtained in step (1) at a rate of 3°C / min to 550°C, hold it for 16 hours and then roll ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com