Scandium and strontium compound microalloyed high zinc 2099 type aluminium alloy and preparation method thereof

A technology of micro-alloying and aluminum alloy, applied in the field of Al-Cu-Li-Zn-Mg-Zr type aluminum alloy and its preparation, scandium and strontium composite micro-alloyed high-zinc 2099 type aluminum alloy and its preparation field, It can solve problems such as restricting development, and achieve the effect of improving comprehensive performance, maintaining weldability and anisotropy, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

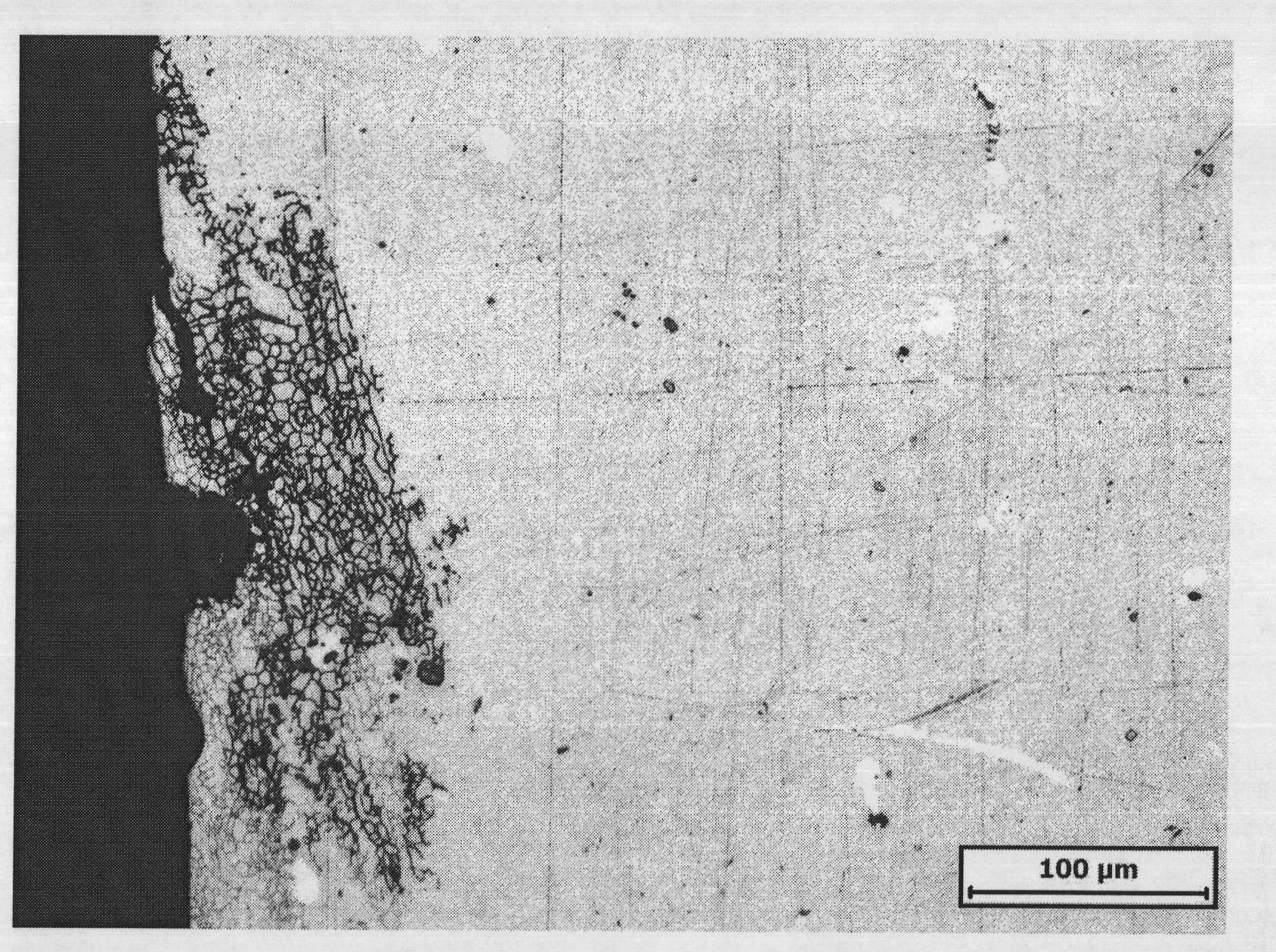

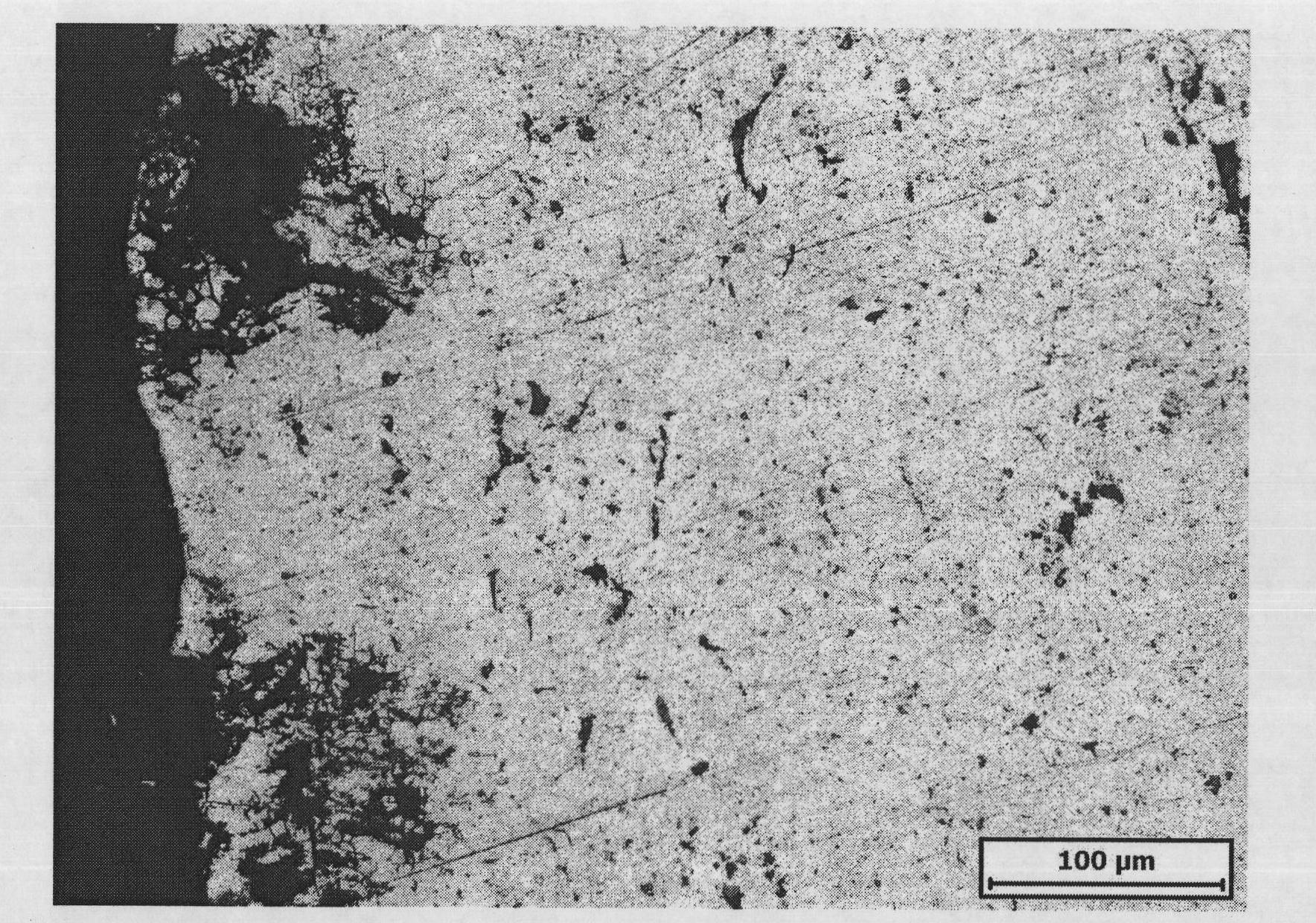

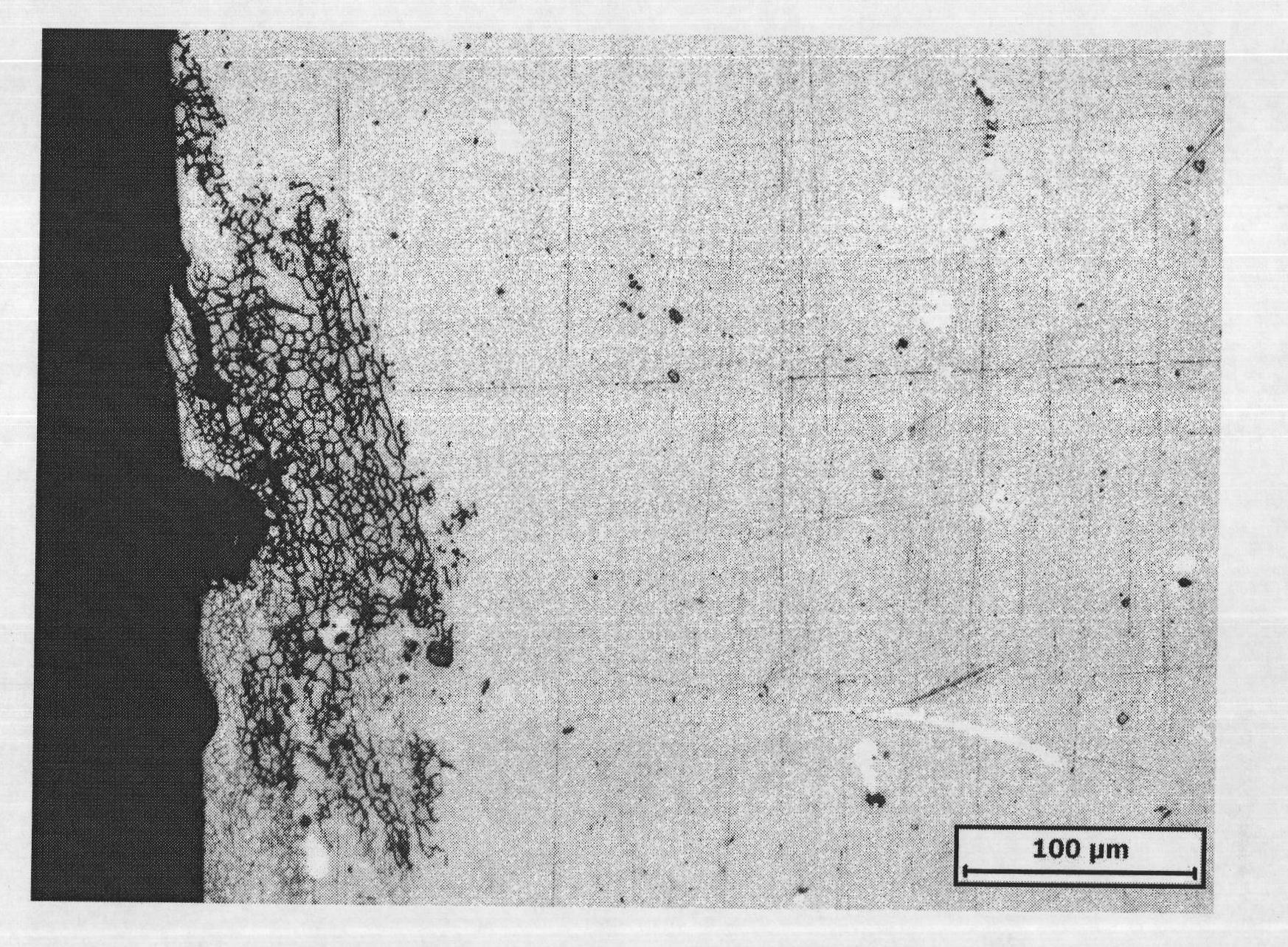

[0024] Such as figure 1 , 2 shown

[0025] A scandium and strontium composite microalloyed high-zinc 2099 aluminum alloy, manufactured by the following method:

[0026] Take 28kg as an example.

[0027] First melt 22.884kg A00 grade pure Al (composition: 99.79Al, 0.14Fe, 0.04Si, the numbers before the element symbols in all the examples represent mass percentages) and then add 1.39kg Al-Cu master alloy (49.62Al, 50.12 Cu, 0.15Fe, 0.11Si) (Al-Cu master alloy can be directly purchased from the market according to the ratio, or can be prepared by conventional methods, the loss rate of Cu is about 6.25%), 0.303kgAl-Sr master alloy (89.86Al, 9.89Sr, 0.15Fe, 0.10Si) (Al-Sr master alloy can be directly purchased from the market according to the ratio, or can be prepared by conventional methods, the loss rate of Sr is about 40%), 0.99kg Al-Mn master alloy (89.73 Al, 10.02Mn, 0.19Fe, 0.06Si) (Al-Mn master alloy can be directly purchased from the market according to the proportion, ...

Embodiment 2

[0033] A scandium and strontium composite microalloyed high-zinc 2099 aluminum alloy, manufactured by the following method:

[0034] Take 28kg as an example.

[0035] First melt 22.611kg of A00 grade pure Al (composition: 99.79Al, 0.14Fe, 0.04Si) and then add 1.53kg of Al-Cu master alloy (49.62Al, 50.12Cu, 0.15Fe, 0.11Si) (Al-Cu master alloy can Purchase directly from the market according to the ratio, or prepare by conventional methods, the loss rate of Cu is about 6.25%), 0.445kg Al-Sr master alloy (89.86Al, 9.89Sr, 0.15Fe, 0.10Si) (Al-Sr master alloy Alloys can be directly purchased from the market according to the ratio, or can be prepared by conventional methods, the loss rate of Sr is about 40%), 0.997kg Al-Mn master alloy (89.73Al, 10.02Mn, 0.19Fe, 0.06Si) (Al- Mn master alloy can be directly purchased from the market according to the proportioning ratio, or can be prepared by conventional methods, the loss rate of Mn is about 10%), 0.544kg Al-Zr master alloy (95.69Al,...

Embodiment 3

[0040] A scandium and strontium composite microalloyed high-zinc 2099 aluminum alloy, manufactured by the following method:

[0041] Take 28kg as an example.

[0042] First melt 22.552kg A00 grade pure Al (composition: 99.79Al, 0.14Fe, 0.04Si) and then add 1.466kg Al-Cu (49.62Al, 50.12Cu, 0.15Fe, 0.11Si) master alloy (Al-Cu master alloy can Purchase from the market directly according to the ratio, or prepare by conventional methods, the loss rate of Cu is about 6.25%), 0.382kg Al-Sr master alloy (89.86Al, 9.89Sr, 0.15Fe, 0.10Si) (Al-Sr master alloy It can be directly purchased from the market according to the ratio, or can be prepared by conventional methods, the loss rate of Sr is about 40%), 0.68kg Al-Mn master alloy (89.73Al, 10.02Mn, 0.19Fe, 0.06Si) (Al-Mn The master alloy can be directly purchased from the market according to the ratio, or can be prepared by conventional methods, the loss rate of Mn is about 10%), 0.592kg Al-Zr master alloy (95.69Al, 4.11Zr, 0.20Fe, 0.10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com