Hot dip coating cast aluminium alloy and preparation method thereof

A cast aluminum alloy and hot-dip plating technology, applied in the field of hot-dip cast aluminum alloy and its preparation, can solve problems such as corrosion, and achieve the effects of rapid self-healing damage and full electrochemical corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

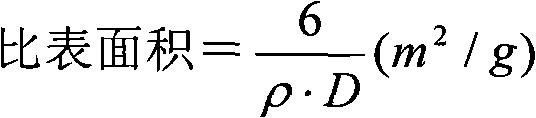

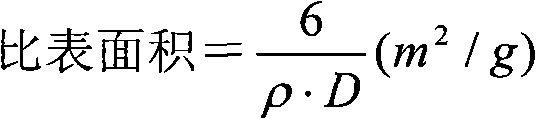

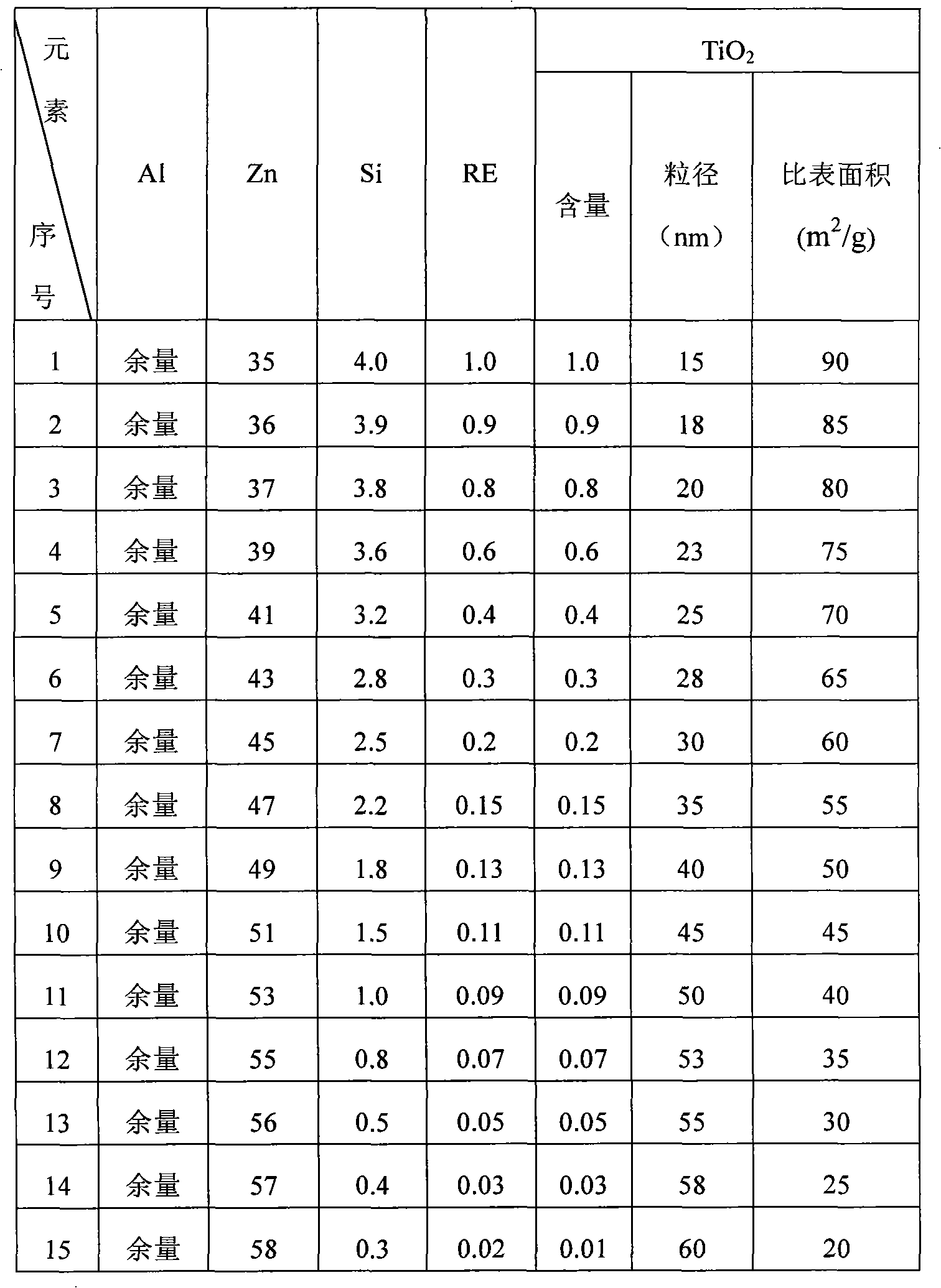

[0050] A hot-dip cast aluminum alloy for anticorrosion treatment of marine weather-resistant engineering parts, which is composed of Zn, Al, Si, RE and TiO 2 The nano-oxide particle enhancer is composed of the total mass percentage of each component: Zn: 35-58%, Si: 0.3-4.0%, RE: 0.02-1.0%, TiO 2 : 0.01~1.0%, Al: balance, and inevitable impurities, the specific mass percentage content and related parameters are shown in Table 1 below:

[0051] Table 1: The mass percentage content (%) of each component in the total weight and related parameters

[0052]

Embodiment 2

[0054] A hot-dip cast aluminum alloy for anticorrosion treatment of marine weather-resistant engineering parts, which is composed of Al, Zn, Si, RE and CeO 2 The nano-oxide particle enhancer is composed of the total mass percentage of each component: Zn: 35-58%, Si: 0.3-4.0%, RE: 0.02-1.0%, CeO 2 : 0.01~1.0%, Al: balance, and inevitable impurities, see Table 2 below for details:

[0055] Table 2: The mass percentage content (%) of each component in the total weight and related parameters

[0056]

Embodiment 3

[0058] The hot-dip alloy is composed of Al, Zn, Si, RE and nano-oxide particle enhancer, wherein the nano-oxide particle is TiO 2 and CeO 2 , and TiO 2 and CeO 2 The ratio is 1:(1~3), in terms of mass percentage: each component accounts for the total mass percentage: Zn: 35-58%, Si: 0.3-4.0%, RE: 0.02-1.0%, nano-oxide particles TiO 2 and CeO 2 Total content: 0.01-1.0%, Al: balance, and inevitable impurities, see Table 3 below for details:

[0059] Table 3: The mass percentage content (%) of each component in the total weight and related parameters

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com