Metal injection moulding method

a metal injection and moulding technology, applied in the direction of coatings, etc., can solve the problems of difficult use of aluminum in metal injection moulding, achieve the effects of improving the wetting characteristics and sintering behaviour of aluminium, promoting the formation of aluminium nitride, and rapid conversion of aluminium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

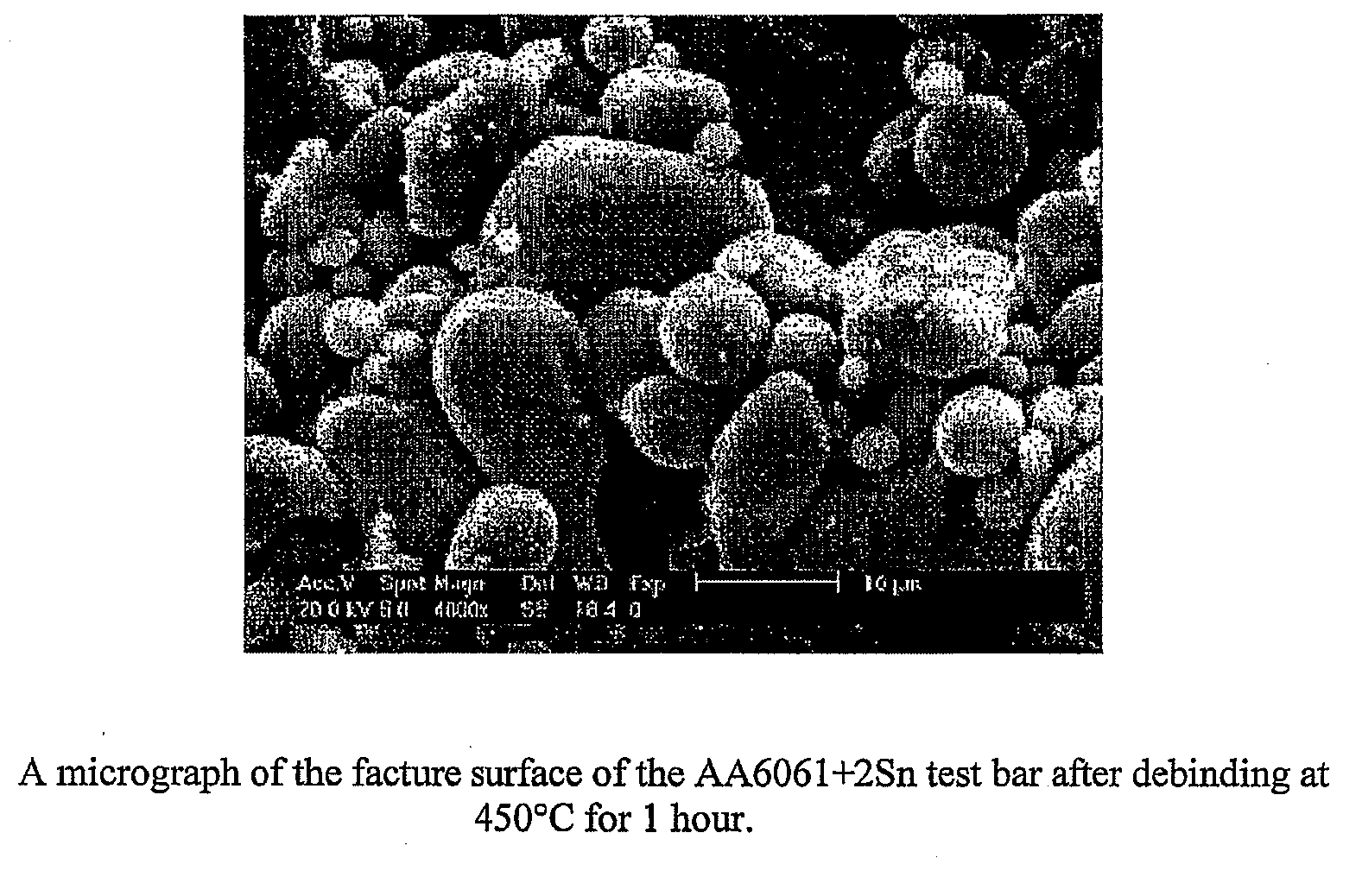

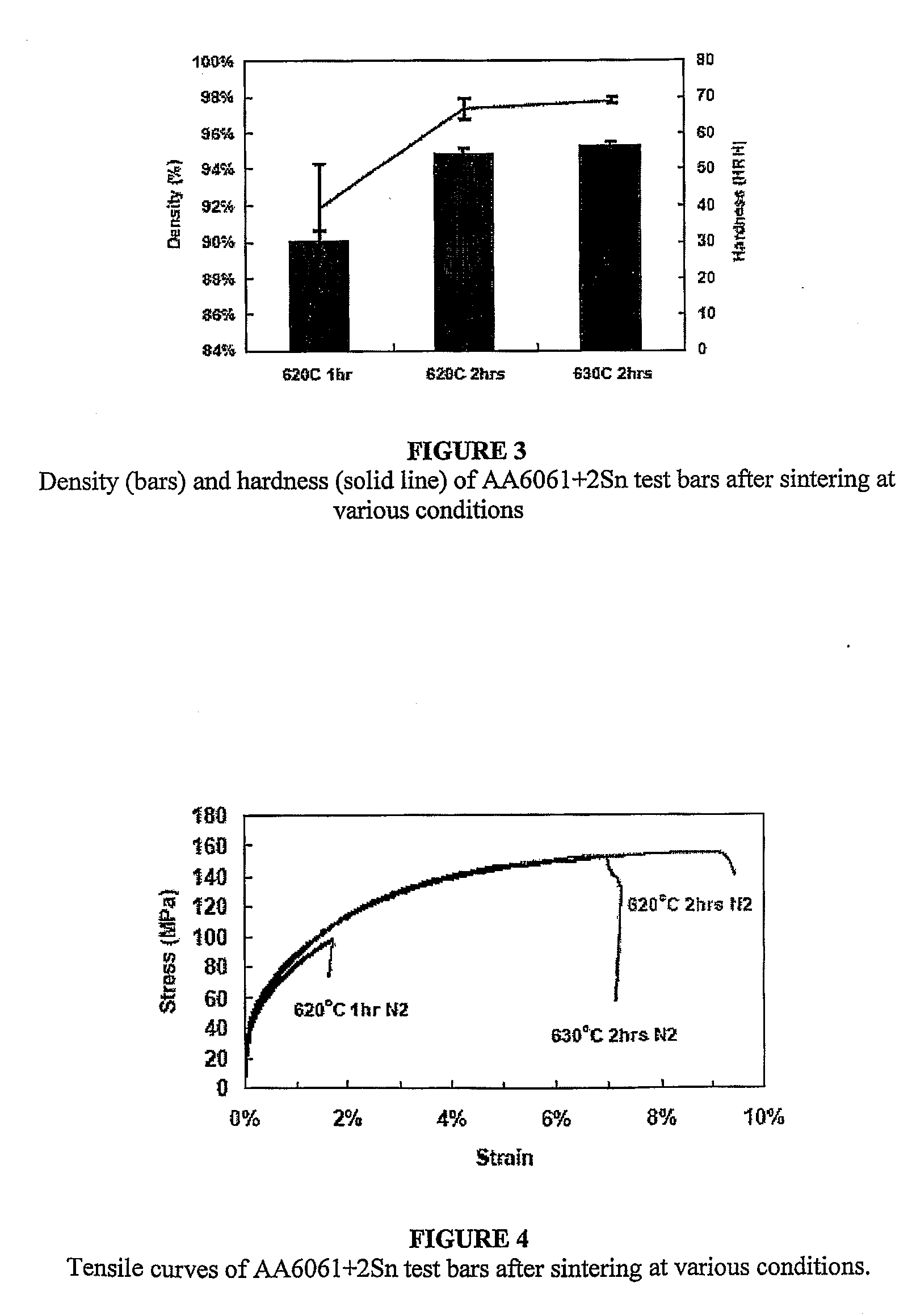

[0057]A variety of alloy and powder compositions, particle sizes and particle shapes were tested. Spherical AA6061 powders with a D50 of 10 μm and spherical Sn with a particle size 82 m were preferred. The metal injection moulding feedstock consisted of 6061 powder with 2 wt % Sn and a binder system of 3 wt % stearic acid, 52wt % palm oil wax and 45 wt % high density polyethylene. The raw materials were mixed at 165° C. for 180 minutes. After granulating, the feedstock was injection moulded into standard tensile bars using an Arburg moulding machine. Solvent debinding was conducted in hexane at 40° C. for 24 hours. The removal of the remaining binder and sintering were combined and conducted in a sealed tube furnace. The preferred atmosphere is high purity nitrogen gas flowing at 1 litre / min. The thermal profile used in the experimental work is shown in Table 1. Magnesium bars were placed around the article during sintering.

[0058]Tensile testing was conducted on as-sintered material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com