Preparation method of sandwich board with aluminium alloy foam core

A technology of aluminum alloy foam and sandwich panels, applied in the direction of metal rolling, etc., can solve the problems of low bonding strength between panels and foam cores, product cost, insufficient output and size, etc., and achieve the effect of overcoming product cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

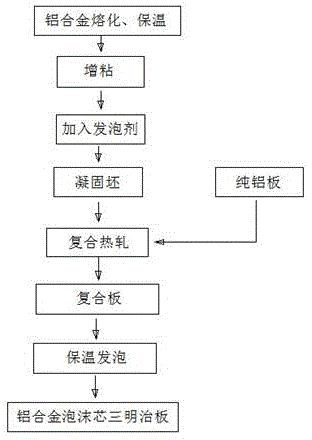

[0022] The preparation method of the aluminum alloy foam core sandwich panel described in this embodiment specifically includes the following steps:

[0023] (1) Alloy melting and heat preservation: Melt the AlSi12 alloy at 600°C and heat it for 30 minutes;

[0024] (2) Viscosification: Add Ca to the AlSi12 alloy melt obtained in step (1), the amount of Ca added is 1.5% of the mass of the AlSi12 alloy melt, and stir at a stirring speed of 1000rpm for 15 minutes to obtain a viscosified AlSi12 alloy melt;

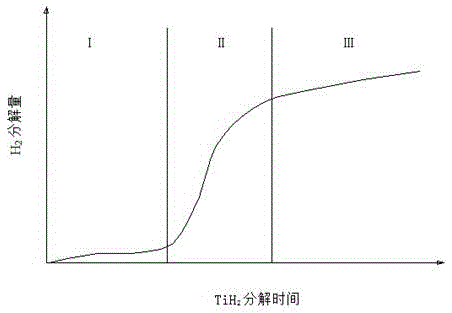

[0025] (3) Add foaming agent: add foaming agent TiH after pre-oxidation treatment at 400°C for 6h + 470°C for 1h to the thickened AlSi12 alloy melt obtained in step (2) 2 , blowing agent TiH 2 The addition amount is 1.0% of the mass of the AlSi12 alloy melt, and the blowing agent TiH 2 The particle size range of the particles is 37~44μm, the stirring speed of the foaming agent is 3000rpm, and the stirring time is 30s, and the solidified billet is obtained after the aluminu...

Embodiment 2

[0029] The preparation method of the aluminum alloy foam core sandwich panel described in this embodiment specifically includes the following steps:

[0030] (1) Aluminum alloy melt melting and heat preservation: Melt the ZL111 alloy at 630°C and heat it for 50 minutes;

[0031] (2) Viscosification: Add Ca to the ZL111 alloy melt obtained in step (1), the amount of Ca added is 2% of the mass of the AlSi12 alloy melt, stir at a stirring speed of 1500rpm for 12 minutes, and obtain a viscosified ZL111 alloy melt;

[0032] (3) Add foaming agent: add foaming agent TiH pre-oxidized at 400°C for 6h+490°C for 1h to the thickened ZL111 alloy melt obtained in step (2) 2 , blowing agent TiH 2 The addition amount is 1.5% of the mass of the ZL111 alloy melt, and the blowing agent TiH 2 The particle size range of the particles is 44~53μm, the stirring speed of the foaming agent is 2000rpm, the stirring time is 50s, and the solidified billet is obtained after the aluminum alloy melt is co...

Embodiment 3

[0036] The preparation method of the aluminum alloy foam core sandwich panel described in this embodiment specifically includes the following steps:

[0037] (1) Melting and heat preservation of aluminum alloy melt: Melt 7075 alloy at 670°C and heat it for 40 minutes;

[0038] (2) Viscosification: Add Ca to the 7075 alloy melt obtained in step (1), the amount of Ca added is 1.5% of the mass of the 7075 alloy melt, and stir at a stirring speed of 1800rpm for 13 minutes to obtain a viscosified 7075 alloy melt;

[0039](3) Add foaming agent: add foaming agent TiH pre-oxidized at 400°C for 6h+520°C for 1h to the thickened 7075 alloy melt obtained in step (2) 2 , blowing agent TiH 2 The amount of addition is 2% of the mass of the 7075 alloy melt, and the blowing agent TiH 2 The particle size range of the particles is 53~61μm, the stirring speed of the foaming agent is 1000rpm, the stirring time is 100s, and the solidified billet is obtained after the aluminum alloy melt is coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com