Shaping method of aluminium alloy section

A kind of technology of aluminum alloy and aluminum alloy plate, which is applied in the field of forming of aluminum alloy material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Next, examples of the present invention will be described. After the room-temperature-aged Al alloy sheet was subjected to the recovery treatment of the present invention, its press formability and hemming type were evaluated.

[0086] That is, the 6000-series Al alloy sheets with the Si-excess composition of A shown in Table 1 were left at room temperature for 4 months, and subjected to room temperature aging. The tensile test resistance of the Al alloy plate aged at this room temperature is compared with the As0.2% yield point of 128MPa and 30% of As elongation of the Al alloy plate after quenching and tempering treatment (just finished). The 0.2% yield point is 163 MPa, the △ yield point increases by 35 MPa, the elongation after aging is 25%, and the △ elongation decreases by 5%. In addition, the average grain size measured by the above-mentioned method for measuring the grain size of the Al alloy sheet after room temperature aging was 30 μm.

[0087] The tensile t...

Embodiment 2

[0100] Next, as an automobile outer panel, the same Al alloy sheet as in Example 1 was press-formed, the sheet was left to age at room temperature, and then hemming was simulated to evaluate the flat hemming workability. These results are shown in Table 3.

[0101] Stamping is carried out as follows. Cut a number of square test plates (plank thick plates) with a side length of 500mm from the Al alloy plate that has just been manufactured and has not been subjected to room temperature aging. Using a mold with a bead, machine Stamping, stretching is formed into a box-shaped panel with a high square cylindrical extension with a side length of 300 mm and a height of 30 mm in the center, and a flat flange edge (width 30 mm) around the extension. The wrinkle suppressing force was 49kN, the lubricating oil was general antirust oil, and the forming speed was 20mm / min under the same conditions.

[0102] This box-shaped panel is subjected to room temperature aging treatment after being...

Embodiment 3

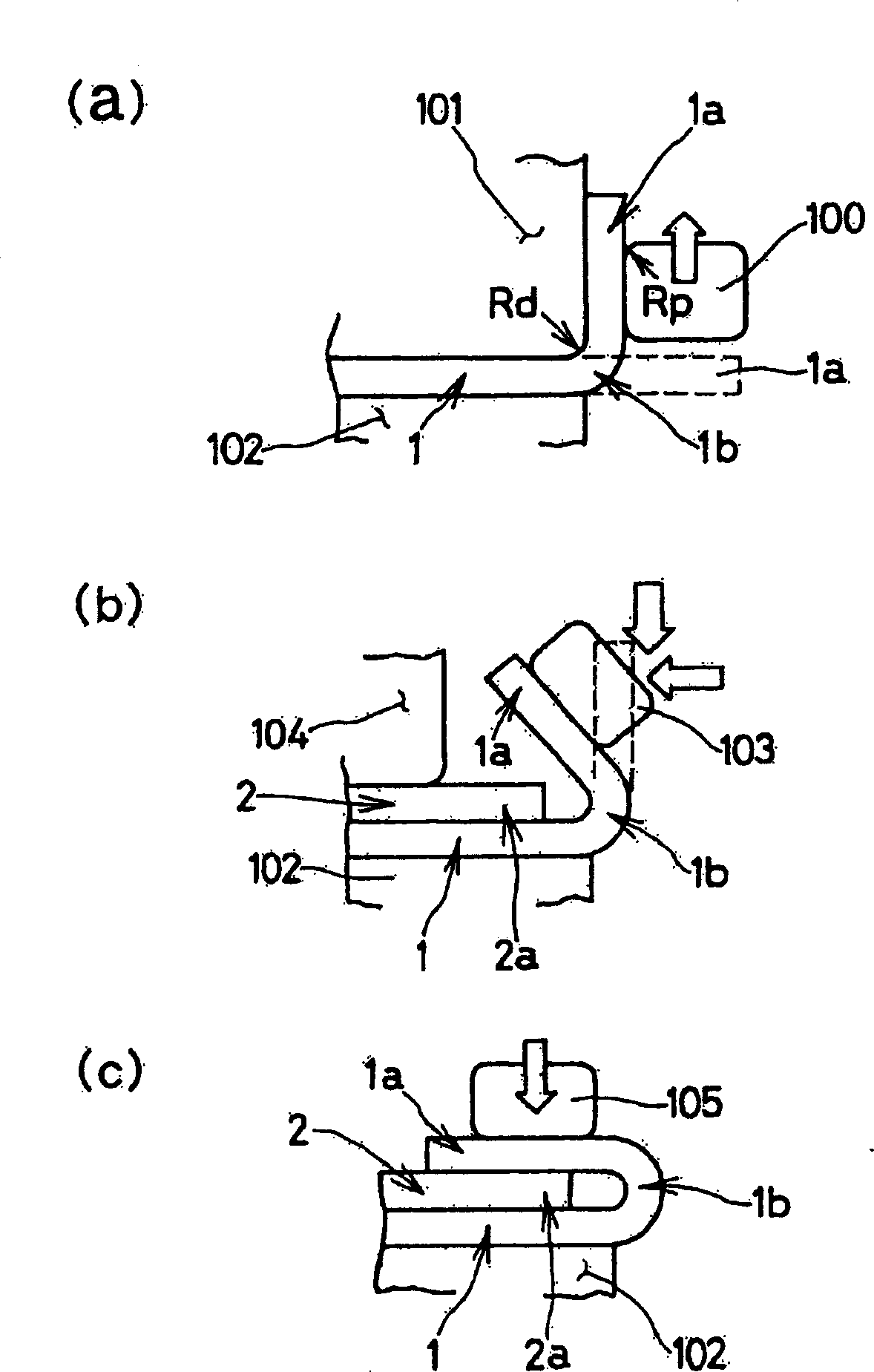

[0116] Next, bending workability after the recovery treatment of the present invention was evaluated for extruded hollow profiles of Al alloys aged at room temperature.

[0117]Specifically, the aluminum alloy billet of each 6000-series component composition shown in Table 1 above was melted by DC casting, subjected to homogenization heat treatment at 480°C×4hr, and extruded at an extrusion temperature of 480°C. , After extrusion, it is directly quenched by water cooling on-line respectively. Next, these extruded materials were jointly subjected to an aging treatment at 190° C. for 3 hours. The extrusion speed was 5 m / min, the extrusion ratio was 61, and the cooling rate during direct quenching was 350° C. / sec.

[0118] This extruded hollow shape has a uniform rectangular (mouth-shaped) section in the longitudinal direction. The long side of the rectangular section is 100mm, the short side is 70mm, and the thickness is 1.5mm.

[0119] The extruded hollow shape was aged for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield point | aaaaa | aaaaa |

| Yield point | aaaaa | aaaaa |

| Yield point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com