Method for casting aluminium alloy

A technology of aluminum alloy and molten aluminum, applied in the field of aluminum alloy casting, can solve problems such as failure to meet requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

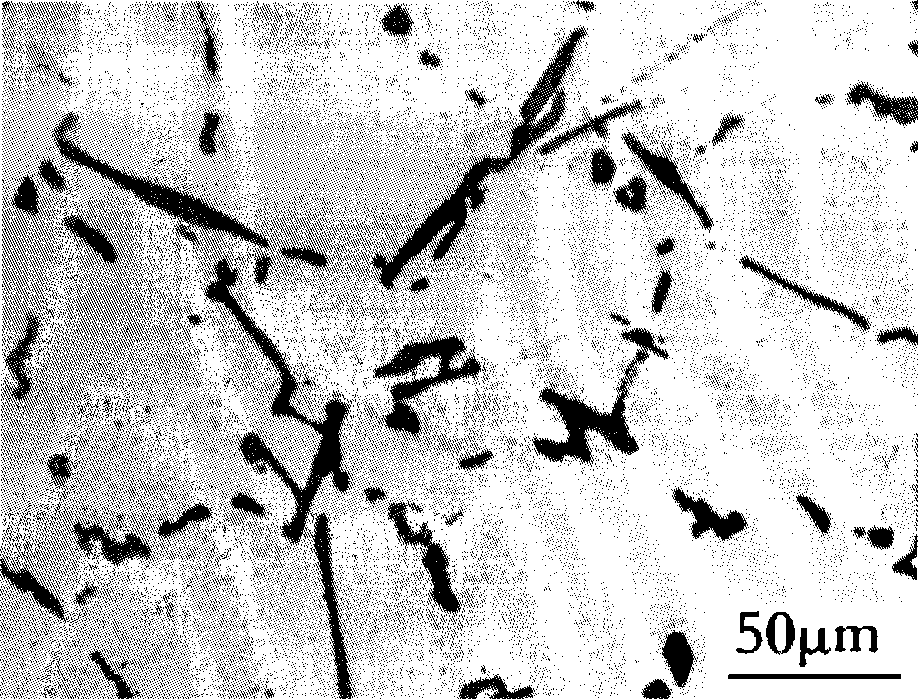

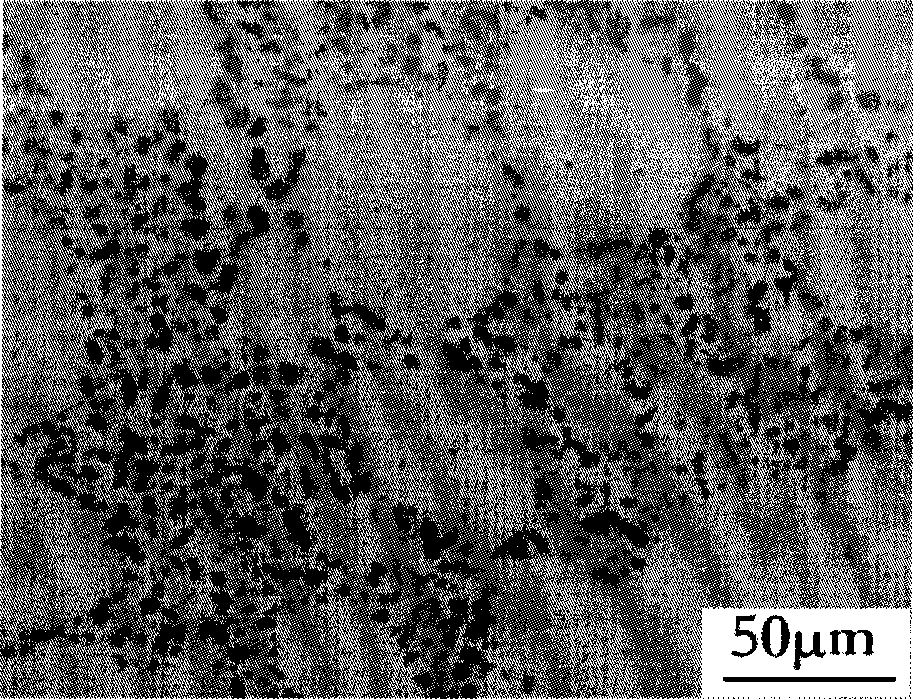

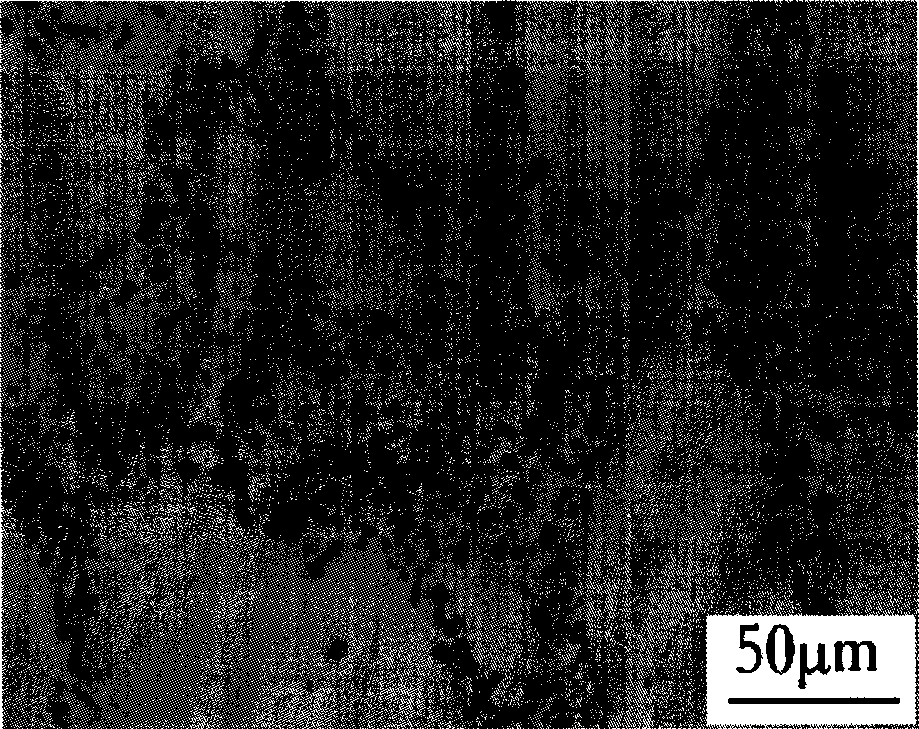

Image

Examples

Embodiment 1

[0031]Melting: smelting the aluminum ingot, the brand name of the aluminum ingot used is ZL101, purchased from Baotou Aluminum Company, the chemical composition of the aluminum ingot is calculated by mass percentage: Si 6.5-7.5%, Mg 0.20-0.45%, Ti0 .08-0.20%, Fe≤0.20%, Mn≤0.01, Cu≤0.01, Zn≤0.01, and the balance is Al. The bell jars, pouring spoons and slag removal tools used in the smelting process are all pre-painted with zinc oxide paint and dried to obtain molten aluminum.

[0032] Refining: When the temperature of the molten aluminum reaches 710-720°C, use a bell jar to press into the dried additives. The additives are purchased from Shanghai Kaiwan Hardware Processing Factory. For 2-5 minutes, do not remove slag, use a rotary blowing device to feed dry nitrogen, and refine for 15-20 minutes. During the refining process, control the temperature of the molten aluminum at 710-720°C to obtain an aluminum melt; the amount of the above additives is 1.2% of the liquid mass, the...

Embodiment 2

[0036] Melting: smelting the aluminum ingot, the brand name of the aluminum ingot used is ZL101, purchased from Baotou Aluminum Company, the chemical composition of the aluminum ingot is calculated by mass percentage: Si 6.5-7.5%, Mg 0.20-0.45%, Ti0 .08-0.20%, Fe≤0.20%, Mn≤0.01, Cu≤0.01, Zn≤0.01, and the balance is Al. The bell jars, pouring spoons and slag removal tools used in the smelting process are all pre-painted with zinc oxide paint and dried to obtain molten aluminum.

[0037] Refining: When the temperature of the molten aluminum reaches 710-720°C, use a bell jar to press into the dried additives. The additives are purchased from Shanghai Kaiwan Hardware Processing Factory. For 2-5 minutes, do not remove slag, use a rotary blowing device to feed dry nitrogen, and refine for 15-20 minutes. During the refining process, control the temperature of the molten aluminum at 710-720°C to obtain an aluminum melt; the amount of the above additives is 1.0% of the liquid mass, th...

Embodiment 3

[0041] Melting: smelting the aluminum ingot, the brand name of the aluminum ingot used is ZL101, purchased from Baotou Aluminum Company, the chemical composition of the aluminum ingot is calculated by mass percentage: Si 6.5-7.5%, Mg 0.20-0.45%, Ti0 .08-0.20%, Fe≤0.20%, Mn≤0.01, Cu≤0.01, Zn≤0.01, and the balance is Al. The bell jars, pouring spoons and slag removal tools used in the smelting process are all pre-painted with zinc oxide paint and dried to obtain molten aluminum.

[0042] Refining: When the temperature of the molten aluminum reaches 710-720°C, use a bell jar to press into the dried additives. The additives are purchased from Shanghai Kaiwan Hardware Processing Factory. For 2-5 minutes, do not remove slag, use a rotary blowing device to feed dry nitrogen, and refine for 15-20 minutes. During the refining process, control the temperature of the molten aluminum at 710-720°C to obtain an aluminum melt; the amount of the above additives is 1.3% of the liquid mass, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com