Aluminium alloy section and manufacture method thereof

A technology of aluminum alloy profiles and manufacturing methods, applied in the field of aluminum alloys, can solve the problems that the inner wall of steel pipes cannot be coated, the life of laboratory furniture is shortened, and the corrosion rate of Fe is accelerated, so as to achieve product standardization, excellent mechanical strength, and anti-corrosion. The effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

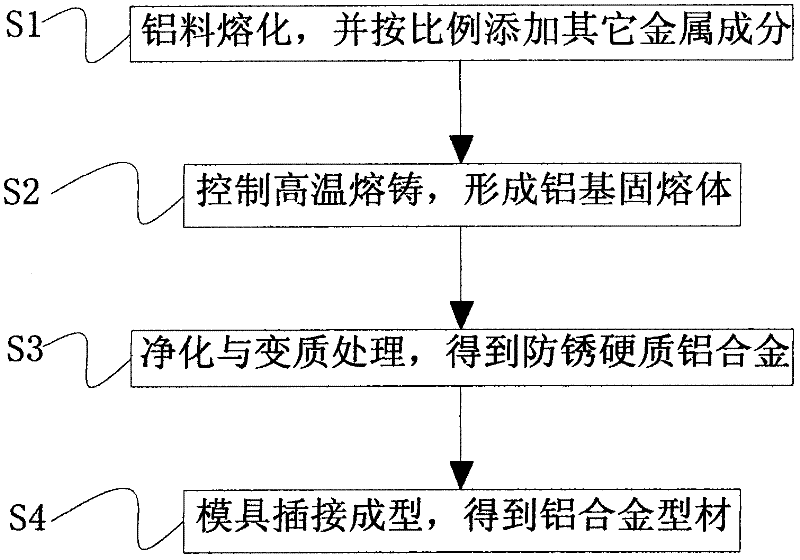

Image

Examples

Embodiment 1

[0023] An aluminum alloy profile, which is made of aluminum as the matrix and other components are added to form a hard aluminum alloy with high compressive strength, suitable for laboratory use.

[0024] Its element composition ratio is: Al 87.5%, Si 0.4%, Fe 1.1%, Mn 0.75%, Mg 0.8%, Zn 2.1%, Cu 4.4%, Ni 0.1%, Ti 0.1%.

[0025] The hard aluminum alloy is anodized to improve its anti-corrosion performance.

[0026] The present invention also relates to a method for making aluminum alloy profiles. Common laboratory aluminum alloy profiles generally use aluminum ingots mixed with magnesium to form forged aluminum. The aluminum alloy profile casting process uses pure aluminum ingots doped with a certain proportion of Cu, Mn, Mg, Metals such as Zn, Ni, and Ti form aluminum-based solid solutions, and the properties of the alloy are strengthened by means of aging strengthening. Anti-corrosion treatment was carried out on the basis to obtain anti-rust duralumin, and finally the prof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com