Pressure cast aluminium alloy and its application

A cast aluminum alloy, hard anodizing technology, applied in the field of material science, can solve the problems of high cost, oxide film thickness, hardness, wear resistance and corrosion resistance are not ideal, oxide film is not easy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

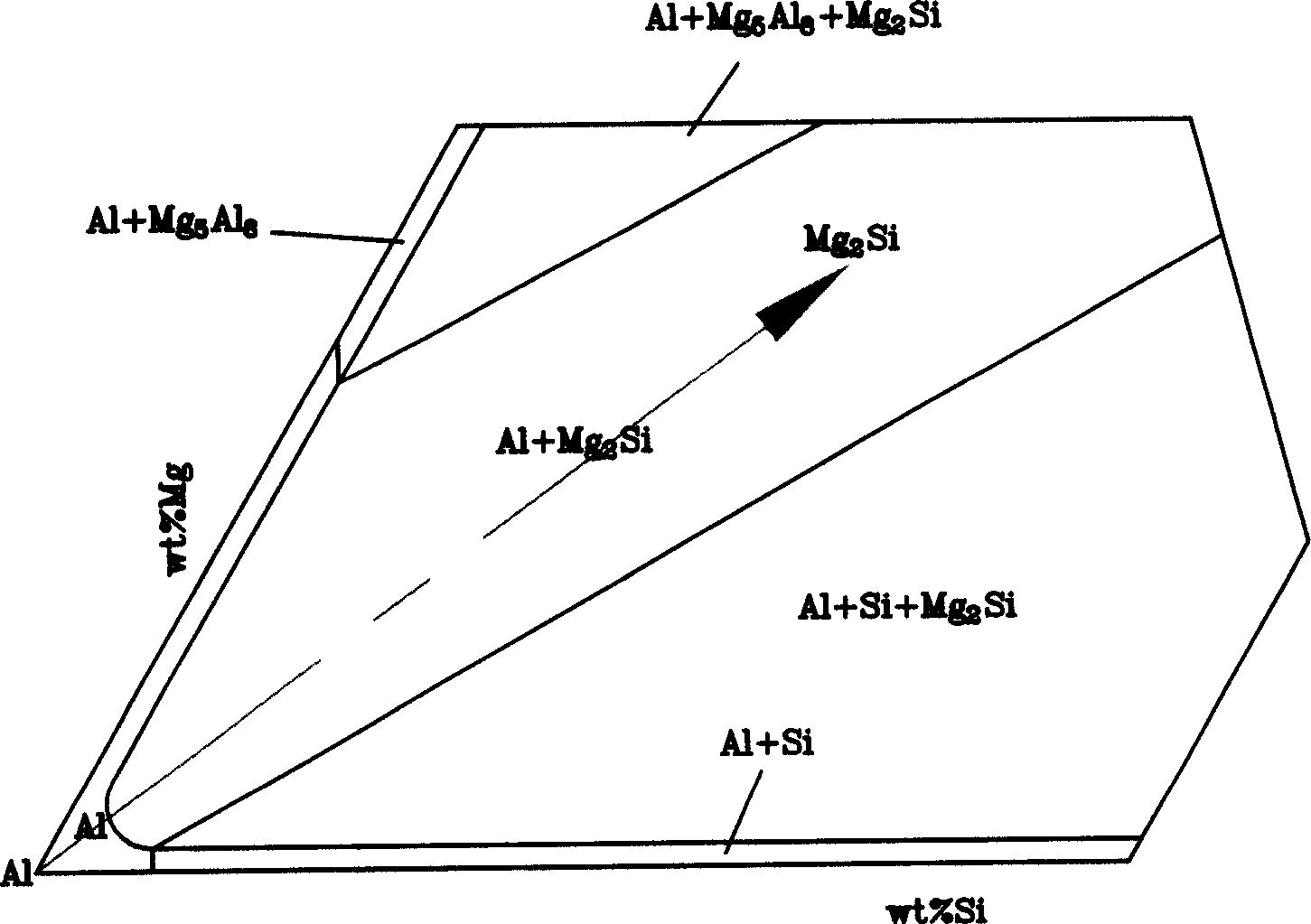

Method used

Image

Examples

Embodiment

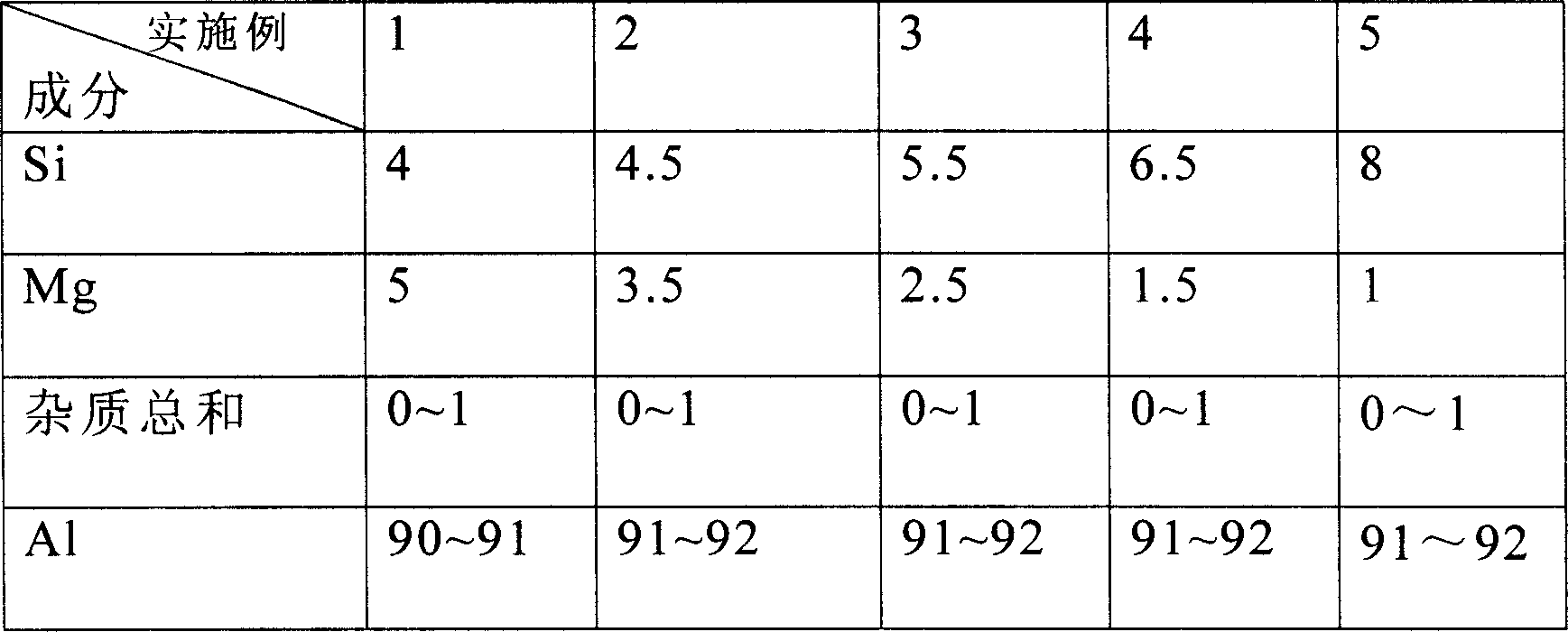

[0026] Embodiment: Formulate alloy according to the composition shown in Table 1. Wherein process composition analysis uses ultraviolet spectrum analyzer (Germany OBLF company to produce) to carry out whole tracking control, the composition of this kind of die-casting aluminum alloy is in GR3-60 industrial electric furnace at 680 ~ Melt at 710°C, pour the melted alloy components into a DC700 die-casting machine and die-cast for 1 minute to make a rough product of die-cast aluminum alloy, remove the excess part after die-casting and the burr on the surface of the rough product of die-cast aluminum alloy prepared above and pass it through Die-cast aluminum alloy is obtained after machining and surface finishing.

[0027] Table 1: Die-casting aluminum alloy composition (weight percent) of the present invention

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com