6410 aluminium alloy and preparation method and application of 6410 aluminium alloy

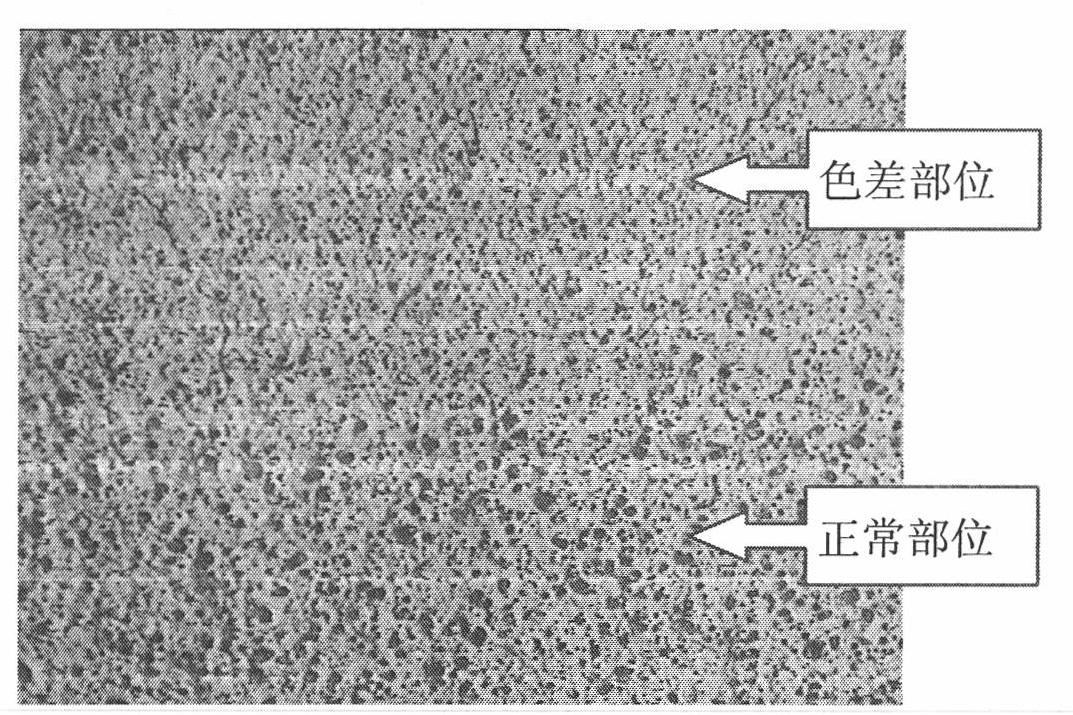

A technology for aluminum alloys and intermediate alloys, applied in the field of aluminum alloys, can solve problems such as easy exposure of alloys and inability to meet the requirements of bright anodizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

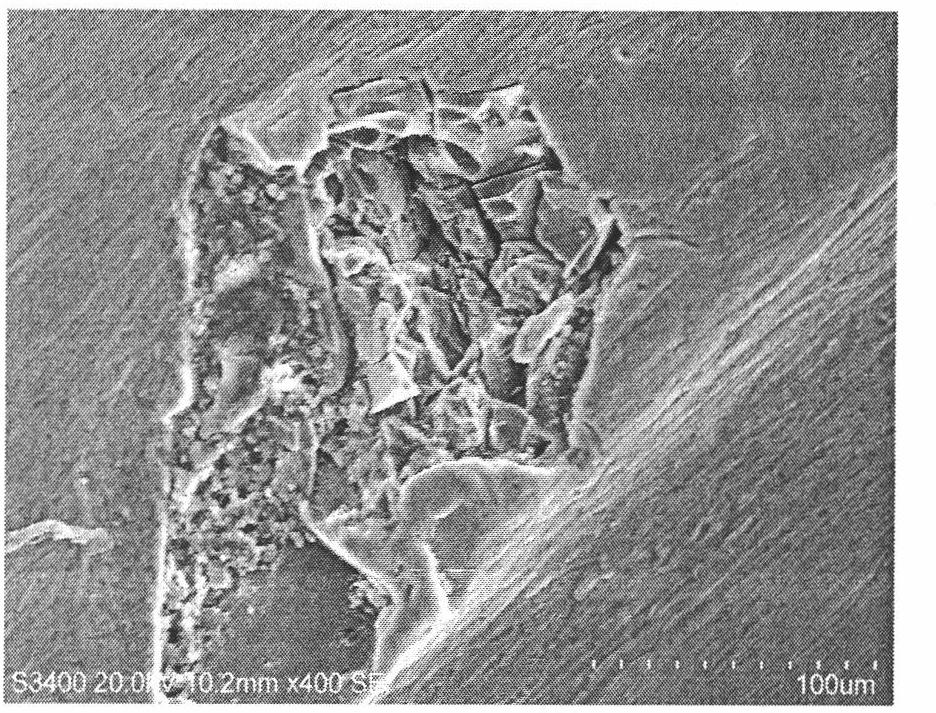

[0055] Take 99.99% high-purity aluminum ingot as raw material to prepare 6401 aluminum alloy for bright anodizing, the target product is Si0.35%, Cu0.08%, Mg0.35%, Ti0.006%, C trace, equivalent to Ti content One-twentieth of Fe≤0.04%, other impurities≤0.01%, and the balance is aluminum, in which Si, Cu, Mg, and Ti are active ingredients, and Fe is the main impurity element whose content needs to be limited. Si element is added in the way of adding aluminum-silicon master alloy to the molten aluminum in the aluminum smelting furnace, Cu element is added in the way of adding aluminum-copper master alloy to the molten aluminum in the aluminum smelting furnace, and Mg is added in the form of refined magnesium It is added to the molten aluminum in the aluminum smelting furnace, and the Ti and C elements are added by continuously adding the AlTi3C0.15 refiner of the aluminum-titanium-carbon intermediate alloy to the casting runner. The following is attached Figure 8 Description of...

Embodiment 2

[0069] Take 99.99% high-purity aluminum ingots as raw materials to prepare 6401 aluminum alloys for bright anodizing. The target product contains 0.55% Si, 0.14% Cu, 0.70% Mg, 0.012% Ti, and a small amount of C, which is equivalent to Ti One-twentieth of the content, Fe ≤ 0.04%, other impurities ≤ 0.01%, the balance is aluminum, of which Si, Cu, Mg, Ti are active ingredients, and Fe is the main impurity element whose content needs to be limited. Si element is added in the way of adding aluminum-silicon master alloy to the molten aluminum in the aluminum smelting furnace, Cu element is added in the way of adding aluminum-copper master alloy to the molten aluminum in the aluminum smelting furnace, and Mg is added in the form of refined magnesium It is added to the molten aluminum in the aluminum smelting furnace, and Ti and C elements are added in the way of continuous addition of AlTi3C0.15 refiner filaments to the furnace casting runner. Refer to Example 1 for the specific pre...

Embodiment 3

[0071] Take 99.99% high-purity aluminum ingots as raw materials to prepare 6401 aluminum alloys for bright anodizing. The target product contains 0.40% Si, 0.10% Cu, 0.45% Mg, 0.006% Ti, and a small amount of C, which is equivalent to Ti One-twentieth of the content, Fe ≤ 0.04%, other impurities ≤ 0.01%, the balance is aluminum, of which Si, Cu, Mg, Ti are active ingredients, and Fe is the main impurity element whose content needs to be limited. Si element is added in the way of adding aluminum-silicon master alloy to the molten aluminum in the aluminum smelting furnace, Cu element is added in the way of adding aluminum-copper master alloy to the molten aluminum in the aluminum smelting furnace, and Mg is added in the form of refined magnesium It is added to the molten aluminum in the aluminum smelting furnace, and Ti and C elements are added in the way of continuous addition of AlTi3C0.15 refiner filaments to the furnace casting runner. Refer to Example 1 for the specific pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com