Aluminium alloys brazing sheet for thin tubes

A technology of aluminum alloy and brazing sheet, applied in the field of aluminum alloy brazing sheet, can solve the problems of corrosion resistance reduction, penetration, failure and the like of the brazing sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the brazing sheet is also optimized to achieve the best properties of the brazing sheet. The final distribution profile of Mn, Cu and Si in solid solution and thus its corrosion protection after brazing depends on the processing history of the sheet.

[0038] The ingot of the brazing sheet was preheated <550°C prior to hot rolling. This process route was chosen to produce a core material with a large Mn-containing dispersion that is small enough to dissolve during the brazing process and thereby maximize the amount of Mn in solid solution. Temper H24 is preferred over temper H14. It has been found that the potential gradient from the outer braze cladding side is steeper when the material is prepared in temper H24 than when it is prepared in temper H14 hours.

[0039] Therefore, the tempering of the core of the aluminum alloy brazing sheet according to the invention is preferably H24, the core sheet and the cladding sheet being advantageously ...

Embodiment 1

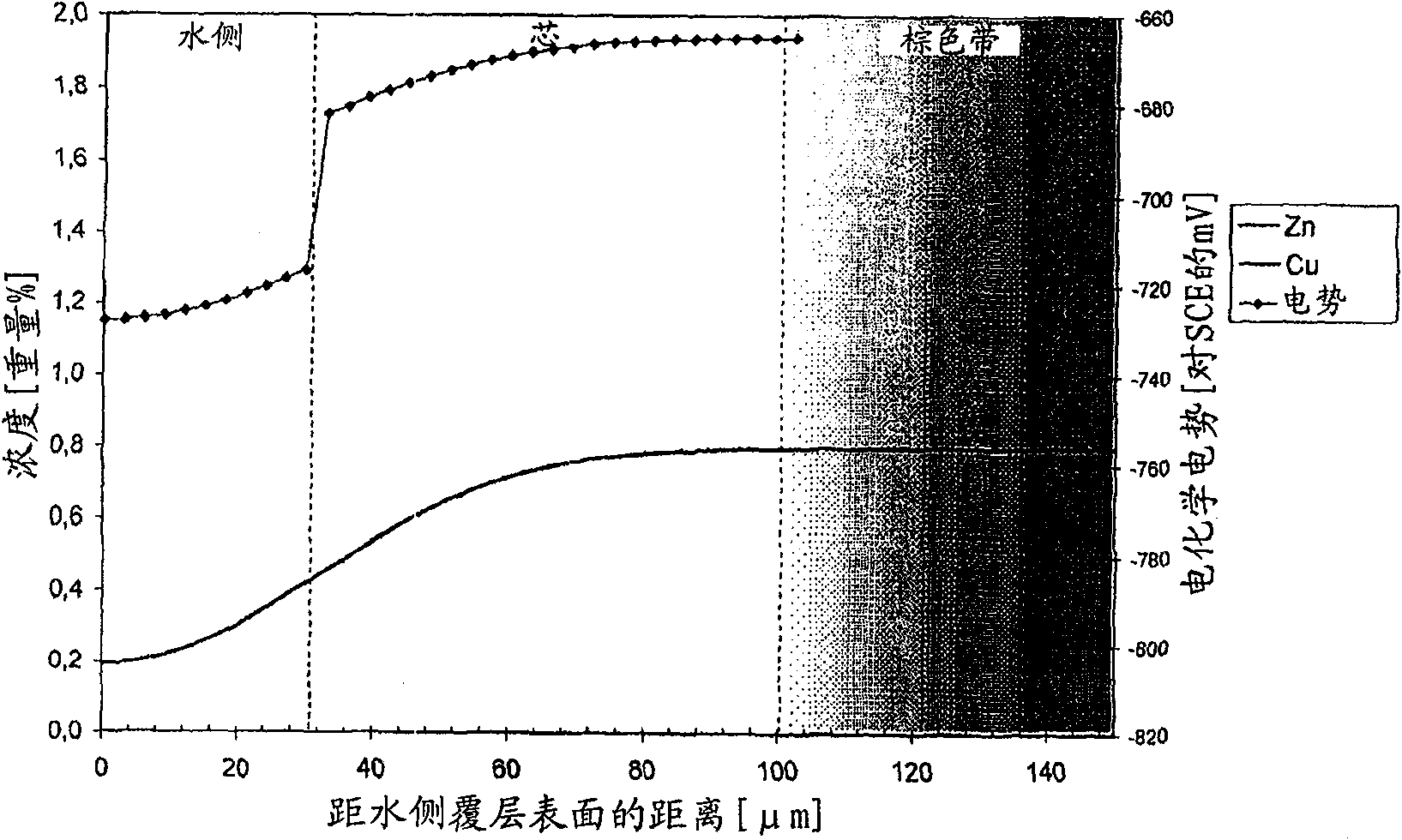

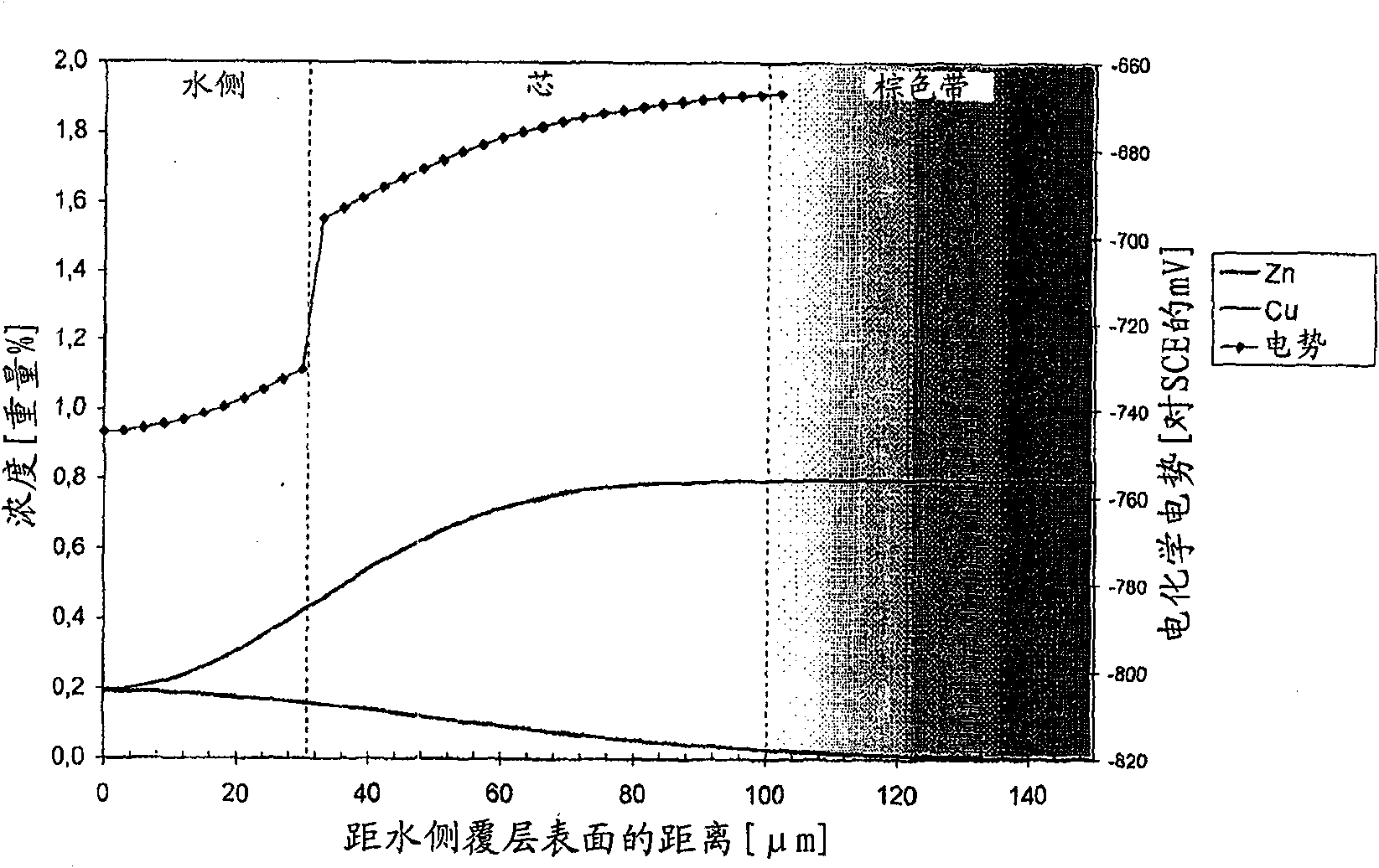

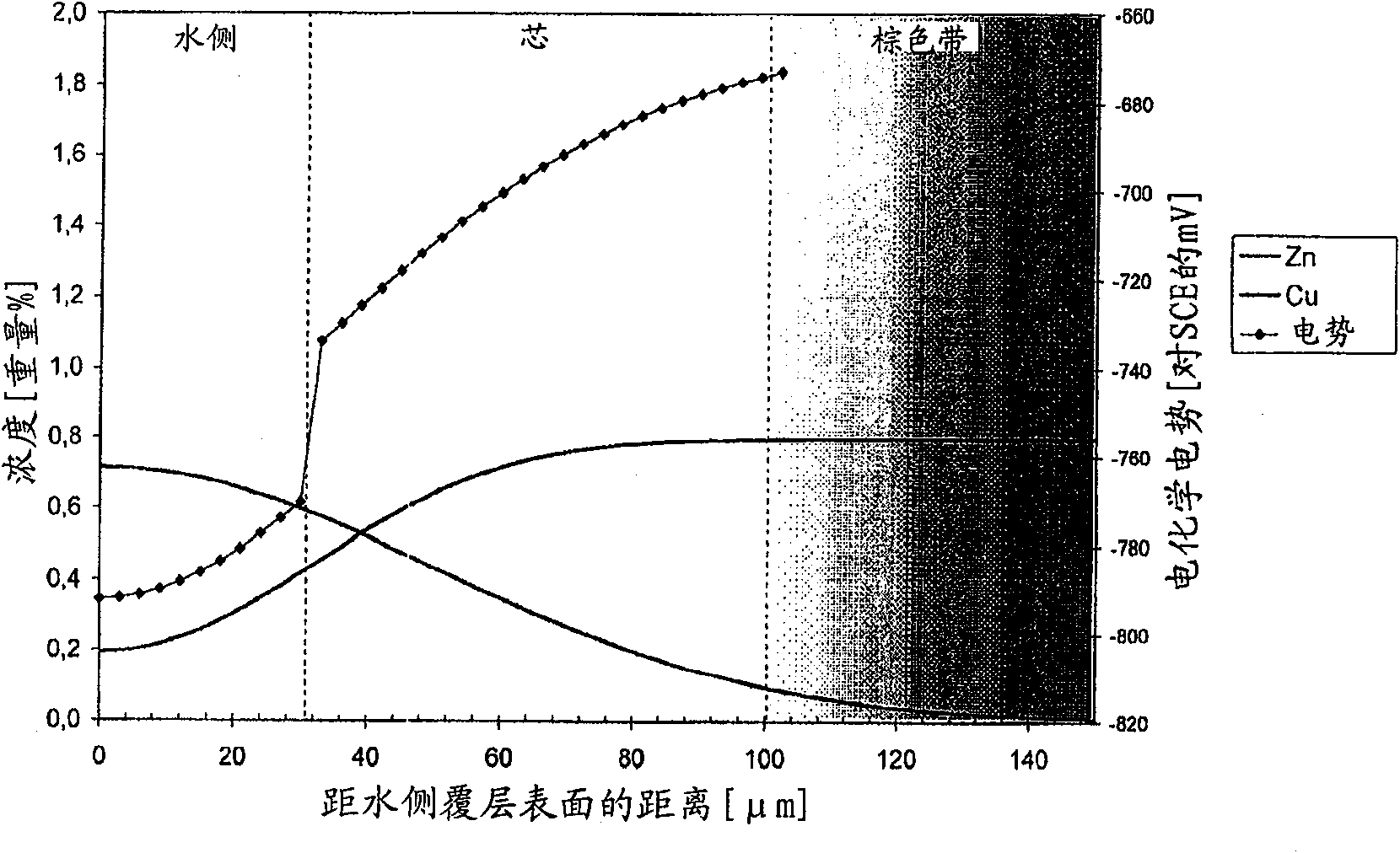

[0043] Concentration curves were calculated using the erf solution of Fick's second law of diffusion (Equation 1). Terms and definitions are given in Table 1. Validation of activation energy Q and maximum diffusion constant D for these alloy systems with experimental data (EPMA, Electron Probe Microanalysis) 0 . For Cu, use 130kJ / mol for Q and D 0 =6.5×10 -5 m 2 / s. For Zn, use Q and D of 114kJ / mol 0 =2.59×10 -5 m 2 / s.

[0044] Calculate the concentration "C" at a distance "y" from the waterside cladding surface after brazing using the following formula:

[0045] C=C 芯 +0.5*ΔC(Erf(A)-Erf(B)) (1)

[0046] A = ( y + h ) / ( 4 Dt ) - - - ( 2 )

[0047] B = ( y - ...

Embodiment 2

[0073] Another aspect of the invention is internal corrosion protection. The potential difference between the water-side cladding surface and the core of Brazing Sheet Example 1 was 63 mV. In brazing sheet example 4 (Table 6), where a thinner water side cladding was used, the potential difference after brazing was 54 mV. The internal corrosion performance of the material was tested.

[0074] Material sheet samples E and D were prepared by using cores with the compositions given in Table 7. A hot-rolled material of the core material is used. Its original cover has 10% AA4343 braze cladding and 10% water side cladding. The waterside coating was removed and replaced with a waterside coating according to the composition in Table 8.

[0075] Table 7 Chemical composition of the core as determined by OES, wt%

[0076]

[0077] Table 8 Chemical composition of the waterside alloy determined by OES, wt%

[0078] water side

[0079] Sample E is a comparative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com