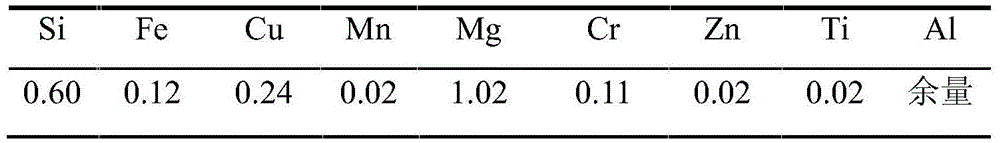

Technological method for carrying out solid solution and aging thermal treatment on 6061 aluminum alloy

A technology of solid solution aging and process method, which is applied in the field of heat treatment of metal materials, can solve the problems of low current aging of aluminum alloys, achieve excellent mechanical properties, and reduce heat treatment energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

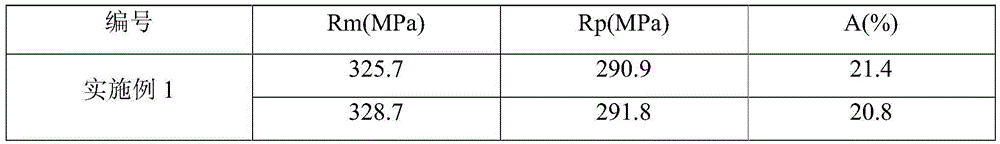

Embodiment 1

[0031] The process method of electric current solution aging heat treatment of 6061 aluminum alloy specifically includes the following steps:

[0032] Step 1, Homogenization:

[0033] Put the as-cast 6061 aluminum alloy round bar with a size of Φ160×580mm into the air circulation heat treatment furnace, feed 500A direct current through copper fixtures to both ends of the ingot, heat it to 550°C, keep it warm for 8 hours, stop the current flow, Cool the furnace to room temperature in air to obtain an ingot;

[0034] Step 2, hot extrusion:

[0035] Put the ingot into the heating furnace, preheat it to 500°C, keep it warm for 2 hours, take it out of the furnace and carry out extrusion molding to obtain a billet with a size of 10×200×12000mm, wherein the extrusion speed is 3.0mm / s and the extrusion ratio 10, the extruded billet is air-cooled and cut;

[0036] Step 3, solution treatment:

[0037] Put the billet with the size of 10×20×580mm into the air circulation heat treatmen...

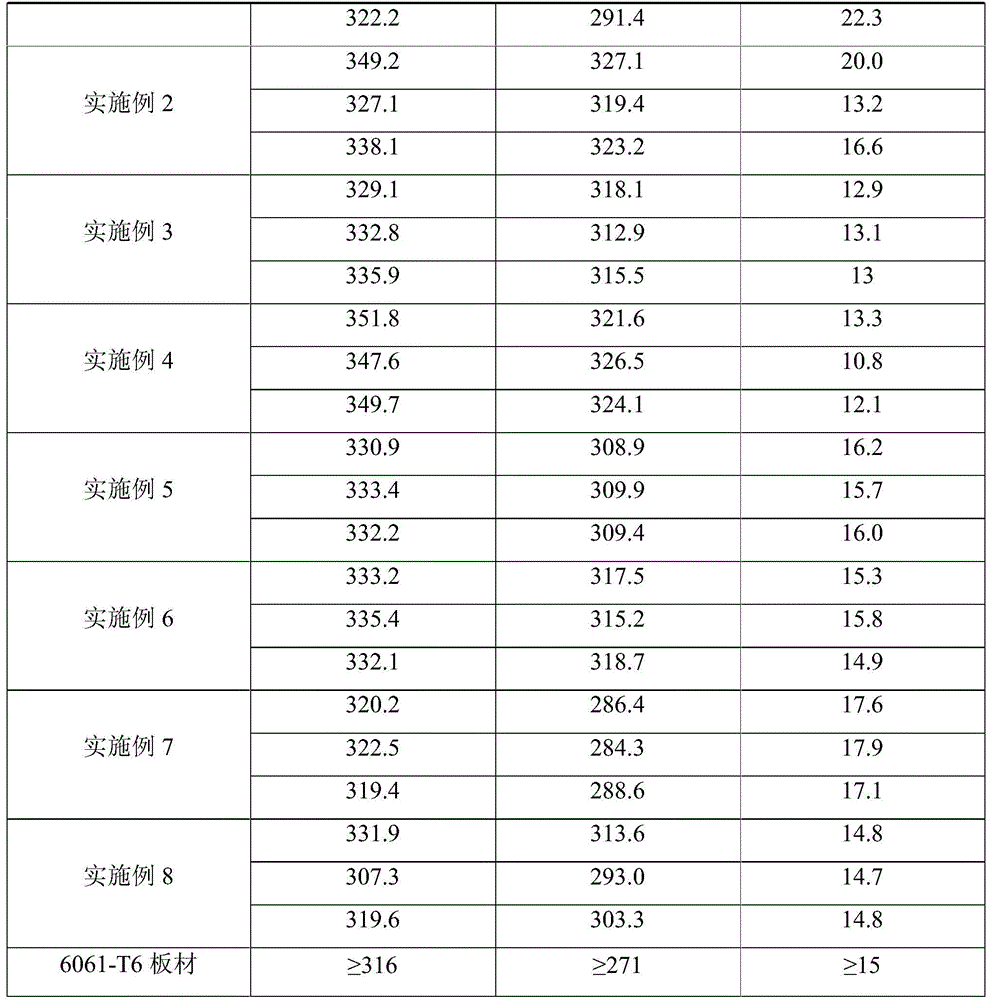

Embodiment 2

[0041] The process method of electric current solution aging heat treatment of 6061 aluminum alloy specifically includes the following steps:

[0042] Step 1, Homogenization:

[0043] Put the as-cast 6061 aluminum alloy round bar with a size of Φ160×580mm into the air circulation heat treatment furnace, feed 500A direct current through copper fixtures to both ends of the ingot, heat it to 550°C, keep it warm for 10h, stop the current flow, Cool the furnace to room temperature in air to obtain an ingot;

[0044] Step 2, hot extrusion:

[0045] Put the ingot into the heating furnace, preheat it to 500°C, keep it warm for 2 hours, take it out of the furnace and carry out extrusion molding to obtain a billet with a size of 10×200×12000mm, wherein the extrusion speed is 3.0mm / s and the extrusion ratio 10, the extruded billet is air-cooled and cut;

[0046] Step 3, solution treatment:

[0047] Put the square billet with the size of 10×20×580mm into the air circulation heat treat...

Embodiment 3

[0051] The process method of electric current solution aging heat treatment of 6061 aluminum alloy specifically includes the following steps:

[0052]Step 1, Homogenization:

[0053] Put the as-cast 6061 aluminum alloy round bar with a size of Φ160×580mm into the air circulation heat treatment furnace, feed 500A direct current through copper fixtures to both ends of the ingot, heat it to 560°C, keep it warm for 12h, stop the current flow, Cool the furnace to room temperature in air to obtain an ingot;

[0054] Step 2, hot extrusion:

[0055] Put the ingot into the heating furnace, preheat it to 500°C, keep it warm for 2 hours, take it out of the furnace and carry out extrusion molding to obtain a billet with a size of 10×200×12000mm, wherein the extrusion speed is 3.0mm / s and the extrusion ratio 10, the extruded billet is air-cooled and cut;

[0056] Step 3, solution treatment:

[0057] Put the billet with the size of 10×20×580mm into the air circulation heat treatment fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com