Process method for reducing vacuum brazing defects of 6061 aluminum alloy and clamp

A process method and aluminum alloy technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of low brazing quality, many defects, low pass rate, etc., and achieve wide welding surface and high heat transfer speed Slow, less polluting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

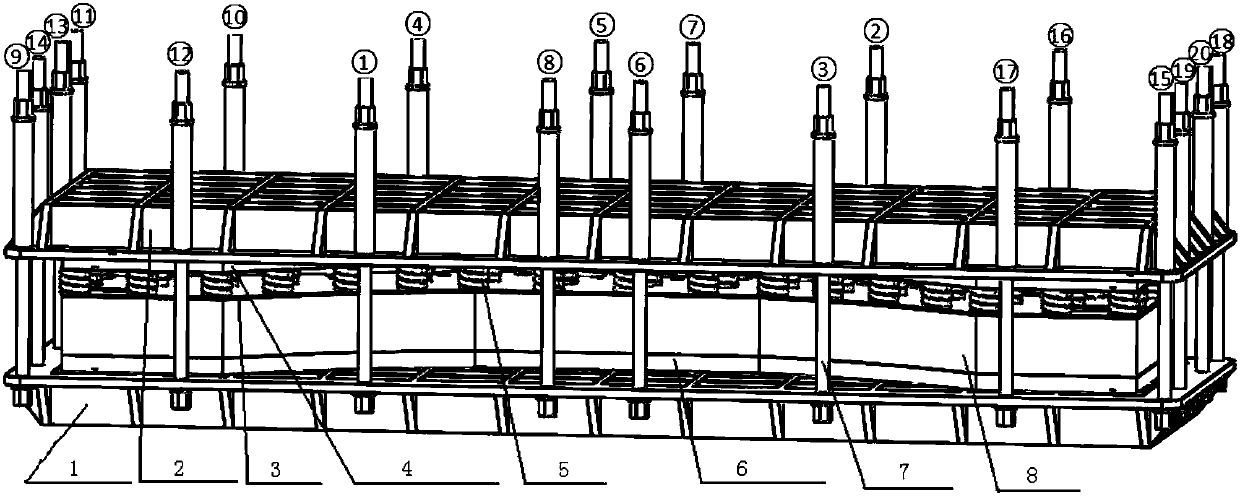

[0049] Such as figure 1 As shown, it is a fixture used for vacuum brazing of 6061 aluminum alloy cold plate. Figure 10-12 , Figure 25 ), a top cover 2 (such as Figure 10-12 , Figure 24 ), an upper stainless steel plate 4 (such as Figures 13 to 15 ), a lower stainless steel plate 6 (such as Figures 13 to 15 ), a backing plate 3 (such as Figures 16-18 ), 20 poles 7 (such as Figure 19 with Figure 20 ), and 32 springs 5 (such as Figure 26 , the springs are symmetrically distributed along the length and width of the cold plate, and the spring spacing is between 18 and 20cm).

[0050] 20 vertical rods 7 link and fix the upper and lower cover plates by threads. During work, the upper cover plate 2 is pressed down by a hydraulic press, and after being pressed down to a specified pressure, the 20 vertical rods 7 are pressed according to the figure 1 The sequence shown in (numbers circled in the figure, namely ), use a torque wrench to tighten (that is, accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com