Production technology for aluminum alloy wire harness installing support for trailer

A technology for installing brackets and aluminum alloy wires, which is applied in the field of aluminum alloy processing, can solve the problems of affecting the stability and service life of wire harnesses, difficult assembly and disassembly, bulky volume, etc., and achieves the effect of simple structure, space saving, light and beautiful overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

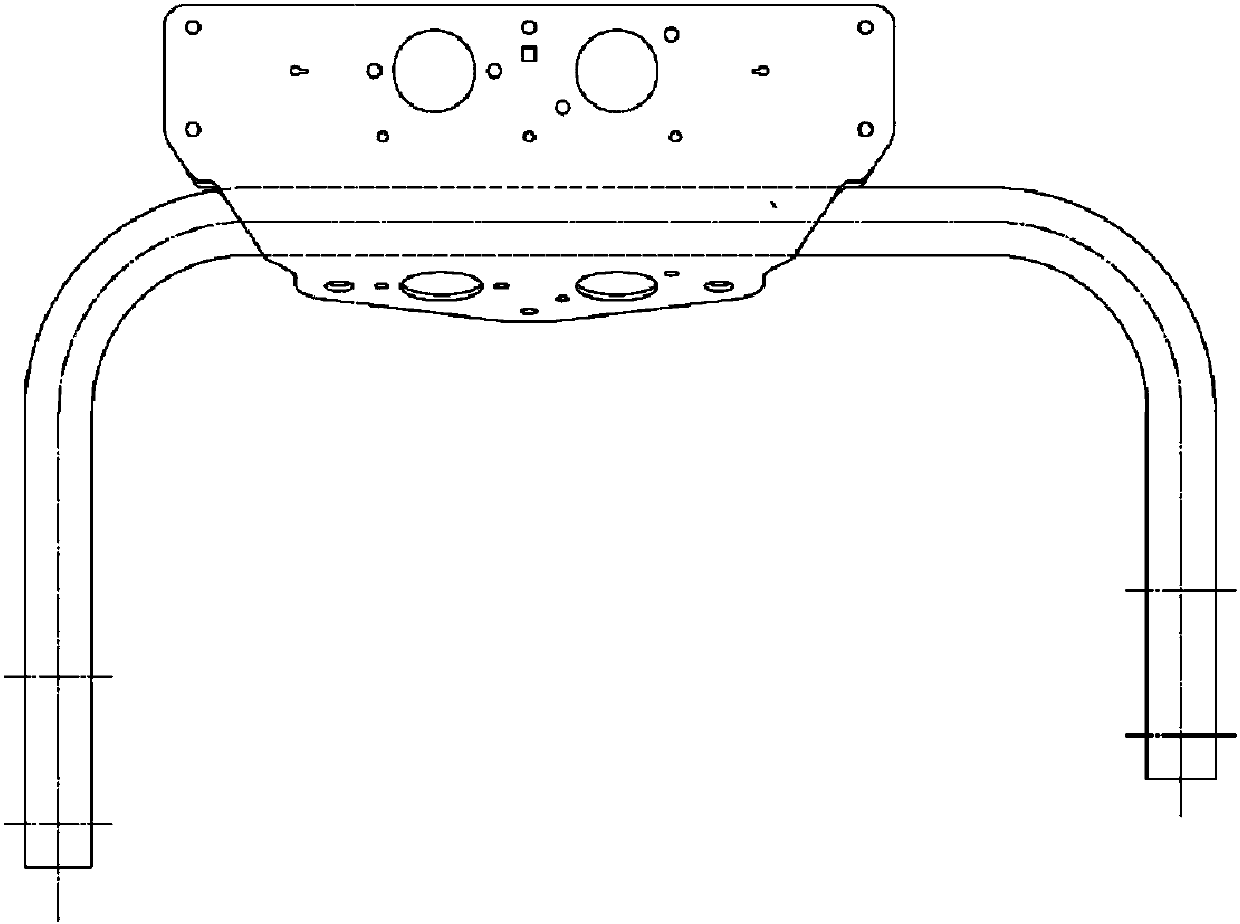

Image

Examples

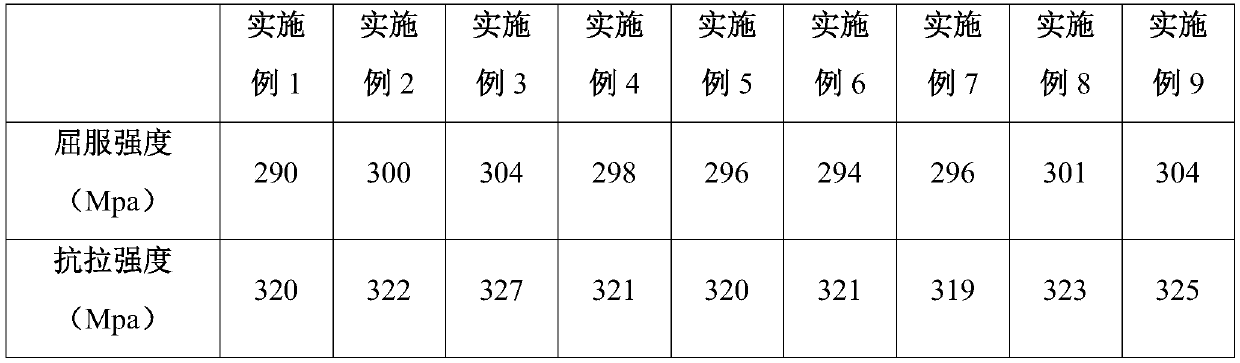

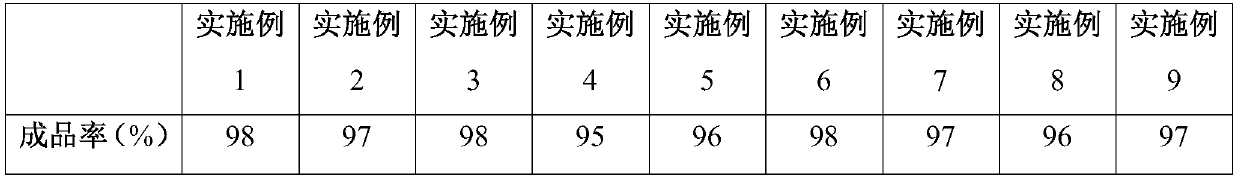

Embodiment 1

[0029] A production process of an aluminum alloy wiring harness mounting bracket for a trailer, comprising the following steps:

[0030] A. Ingredients: The mass percentage ratio of each element in the 6061 aluminum alloy ingot raw material is as follows:

[0031] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Al

content

0.4

0.7

0.15

0.15

0.08

0.04

0.25

0.15

margin

[0032] Prepare aluminum alloy raw materials according to the above ratio;

[0033] B. Melting: put the prepared aluminum alloy raw material and the AlTiB refining agent accounting for 2% of the mass fraction of the aluminum alloy raw material in a melting furnace to melt it into a liquid aluminum alloy, and melt and cast the liquid aluminum alloy into an aluminum alloy ingot. Among them, the melting temperature is 720°C, and the aluminum alloy raw materials in the melting furnace are completely melted and then electromagnetically stirred;

[003...

Embodiment 2

[0041] The difference between Example 2 and Example 1 is that in step A, the mass percentage ratio of each element in the 6061 aluminum alloy ingot raw material is as follows:

[0042] element

Embodiment 3

[0044] The difference between embodiment 3 and embodiment 1 is that in step A, the mass percentage ratio of each element of the 6061 aluminum alloy ingot raw material is as follows:

[0045] element

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com