Method of preparing aluminum alloy wheel hub with high structural strength

A technology of aluminum alloy wheel hub and high structure, which is applied in the field of metal material processing, can solve the problems of complex process, high cost, difficult demoulding, etc., and achieve the effect of simple operation and small mold damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

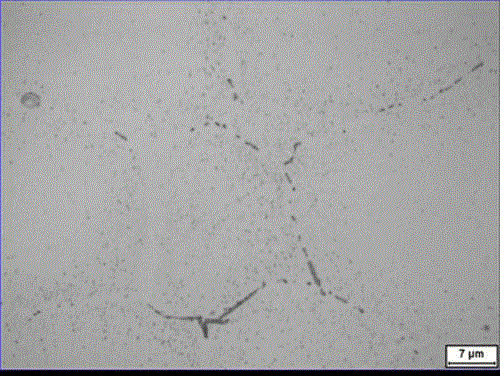

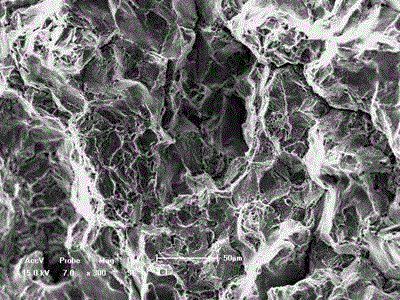

Image

Examples

Embodiment 1

[0021] Method for preparing 21-inch aluminum alloy wheel hub with high structural strength

[0022] (1) Using 6061 aluminum alloy as raw material, melt it in a crucible-type resistance furnace, transfer the smelted aluminum alloy into a static furnace for secondary deep purification, and finally add Al-5Ti-1B modifier, and stand still to obtain aluminum alloy Alloy melt;

[0023] (2) The diversion groove, crystallizer, and dummy bar of the pull-down semi-continuous casting machine are pre-dried, and the aluminum alloy melt is cast by the pull-down semi-continuous casting machine to obtain a semi-solid crystal with equiaxed grains. Solid 6061 aluminum alloy blank, the casting parameters are: temperature is 720°C, electromagnetic stirring frequency is 20Hz, current intensity is 60A, casting speed is 70mm / min, stable casting speed is 110mm / min, liquid surface depth is 145mm, cooling The water flow is 0.095m 3 / min;

[0024] (3) The semi-solid 6061 aluminum alloy billet is heat...

Embodiment 2

[0029] Method for preparing 15-inch aluminum alloy wheel hub with high structural strength

[0030] (1) Using 6061 aluminum alloy as raw material, melt it in a crucible-type resistance furnace, transfer the smelted aluminum alloy into a static furnace for secondary deep purification, and finally add Al-5Ti-1B modifier, and stand still to obtain aluminum alloy Alloy melt;

[0031] (2) The diversion groove, crystallizer, and dummy bar of the pull-down semi-continuous casting machine are pre-dried, and the aluminum alloy melt is cast by the pull-down semi-continuous casting machine to obtain a semi-solid crystal with equiaxed grains. Solid 6061 aluminum alloy blank, the casting parameters are: temperature is 720°C, electromagnetic stirring frequency is 20Hz, current intensity is 60A, casting speed is 60mm / min, stable casting speed is 100mm / min, liquid surface depth is 140mm, cooling The water flow is 0.09m 3 / min;

[0032] (3) The semi-solid 6061 aluminum alloy billet is heate...

Embodiment 3

[0037] Method for preparing 17-inch aluminum alloy wheel hub with high structural strength

[0038] (1) Using 6061 aluminum alloy as raw material, melt it in a crucible-type resistance furnace, transfer the smelted aluminum alloy into a static furnace for secondary deep purification, and finally add Al-5Ti-1B modifier, and stand still to obtain aluminum alloy Alloy melt;

[0039] (2) The diversion groove, crystallizer, and dummy bar of the pull-down semi-continuous casting machine are pre-dried, and the aluminum alloy melt is cast by the pull-down semi-continuous casting machine to obtain a semi-solid crystal with equiaxed grains. Solid 6061 aluminum alloy blank, the casting parameters are: temperature is 720°C, electromagnetic stirring frequency is 20Hz, current intensity is 60A, casting speed is 60mm / min, stable casting speed is 100mm / min, liquid surface depth is 140mm, cooling The water flow is 0.09m 3 / min;

[0040](3) The semi-solid 6061 aluminum alloy billet is heated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com