Method for producing ultrahigh-precision hard disk driving arm sections

A technology of hard disk drive and production method, which is applied in the field of production of ultra-high-precision drive arm profiles, can solve the problems of low hardness, low profile precision, and increased manufacturing cost of hard disk drive arms, and achieves improved yield strength, reduced internal stress, and reduced The effect of bending and twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

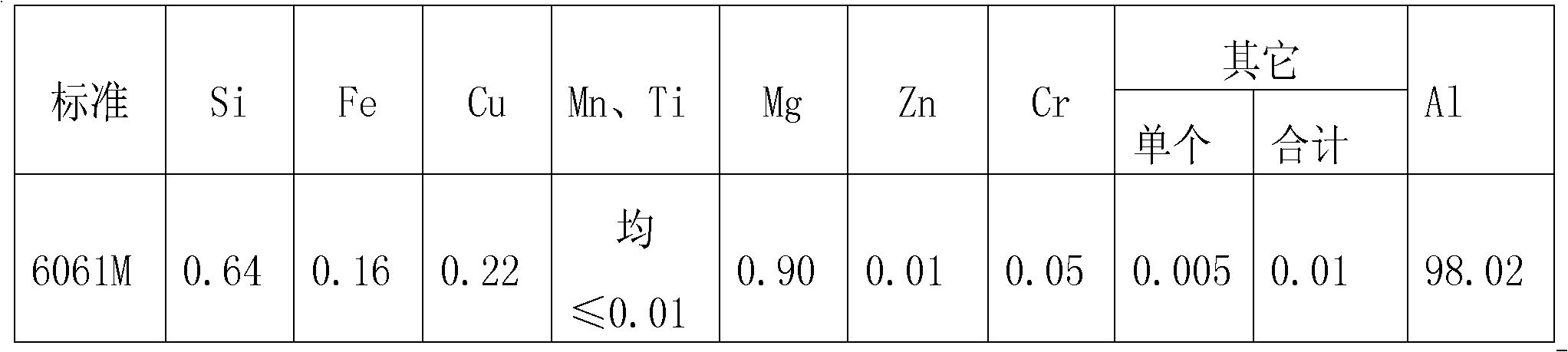

[0031] This embodiment describes the production method of ultra-high-precision hard disk drive arm profiles, producing a certain ultra-high-precision computer hard drive arm aluminum alloy profile, the chemical composition, melting and casting equipment and quality control of the 6061M aluminum alloy round ingot used As follows: (Unit: weight percentage)

[0032]

[0033] The main processes of hot extrusion are as follows:

[0034] Aluminum alloy round ingot melting and casting → homogenization and induction preheating → shunt die design, manufacturing and preheating → hot extrusion forming → online water spray quenching → synchronous traction → interruption → cooling bed cooling → stretching and straightening → fixed Ruler sawing → artificial aging treatment → finished product inspection → packaging and shipping, etc.

[0035] The main equipment used is as follows:

[0036] (1) The hot extrusion forming equipment adopts a 1800 US ton forward single-action extruder. The centering pe...

Embodiment 2

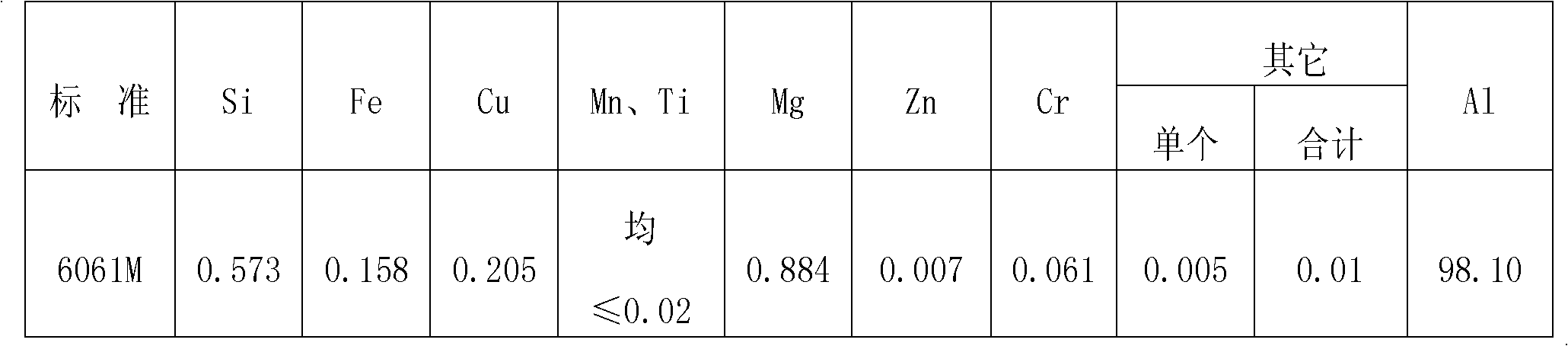

[0069] The production method of ultra-high-precision hard disk drive arm profile described in this embodiment is to produce a certain ultra-high-precision computer hard disk drive arm aluminum alloy profile, the chemical composition, melting and casting equipment and quality control of the 6061M aluminum alloy round ingot used As follows: (Unit: weight percentage)

[0070]

[0071] The main processes of hot extrusion are as follows:

[0072] Aluminum alloy round ingot melting and casting → homogenization and induction preheating → splitter die design, manufacturing and preheating → hot extrusion forming → online water spray quenching → synchronous traction → interruption → cooling bed cooling → stretching and straightening → fixed Ruler sawing → manual aging treatment → finished product inspection → packaging and shipping, etc.

[0073] The main equipment used is as follows:

[0074] (1) The hot extrusion forming equipment adopts a 1250-ton forward single-action extruder. The center...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com