Composite automobile bumper

A car bumper and resin layer technology, which is applied in the direction of bumper, adhesive type, synthetic resin layered products, etc., can solve the problems of car crashes and injuries, heavy accident losses, and the inability to effectively slow down huge collision forces, etc. , to achieve the effect of beautiful appearance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

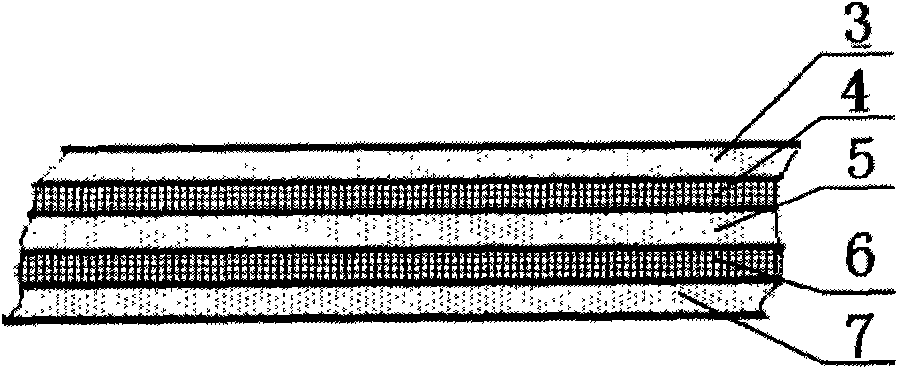

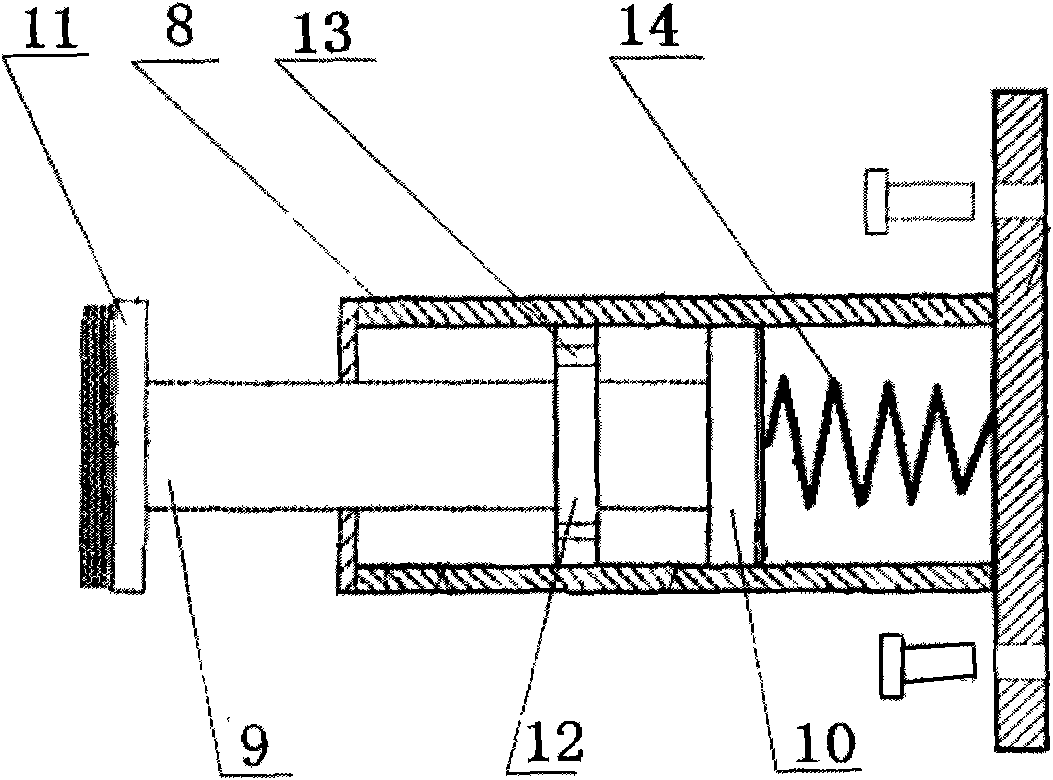

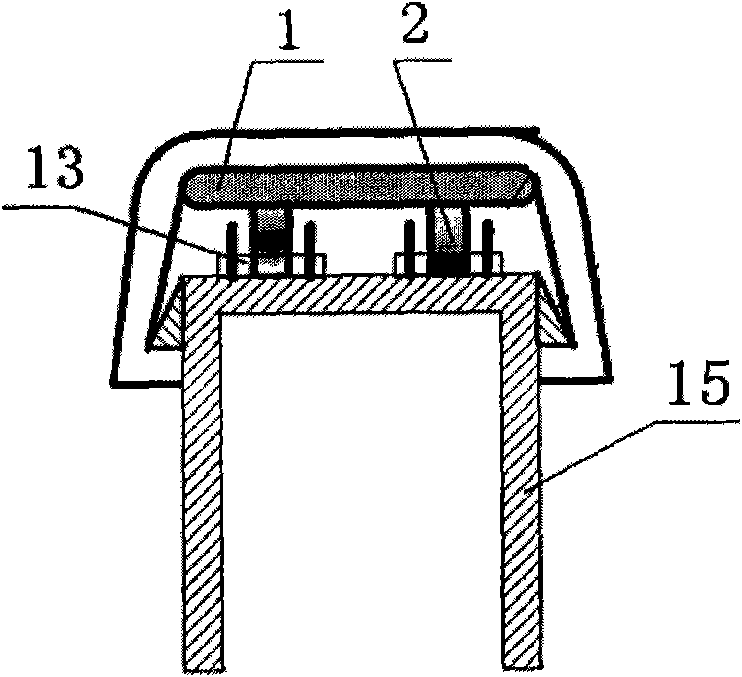

[0015] A composite automobile bumper comprises an outer layer 1 and a collision buffer 2, the outer layer 1 is composed of a gel coat layer 3, a structural layer 4, an adhesive layer 5, a primer layer 6, and a foamed aluminum layer 7, and the gel coat layer 3 is Neopentyl glycol-isophthalic resin;

[0016] Structural layer 4 is 5 layers, namely resin layer, fiber layer, resin layer, fiber layer, resin layer; the formula of resin layer is to add 20 grams of epoxy curing agent T31 and 15 grams of diluent to 100 grams of epoxy resin E-44 Anhydrous ethanol; fiber layer is fiberglass cloth;

[0017] Adhesive layer 5 and primer layer 6 all adopt epoxy resin as the main material, and the formula of adhesive layer 5 is that 100 grams of epoxy resin E-44 add 20 grams of dehydrated alcohol, 70 grams of furyl methylene acetone, diethylene glycol 15 grams of ethylene triamine; the formula of primer layer 6 is 100 grams of E-44 epoxy resin, 20 grams of absolute ethanol, 12 grams of ethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com