Three-layer titanium/aluminum/magnesium composite board and manufacturing method thereof

A composite plate and manufacturing method technology, applied in metal rolling and other directions, can solve the problems that it cannot be used as a space protective layer material, etc., and achieve the effects of improved anti-high-speed impact damage performance, high production efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

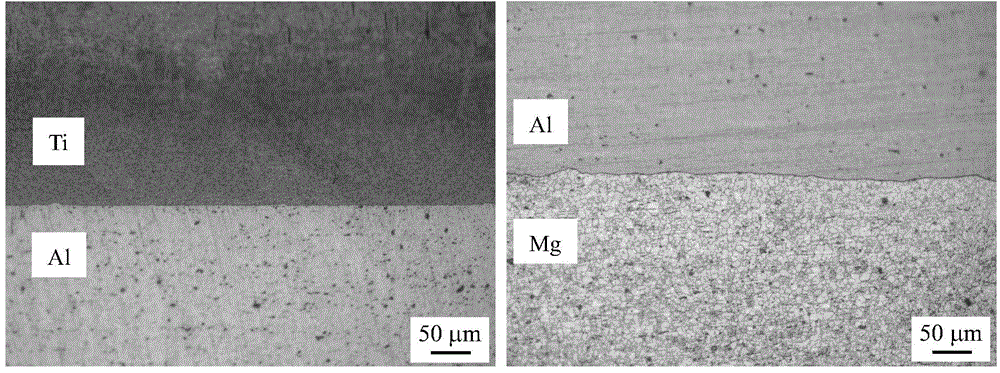

Embodiment 1

[0015] Take 1 piece of TC4 titanium alloy hot-rolled plate, 6061 aluminum alloy hot-rolled plate and AZ31B magnesium alloy hot-rolled plate with a length of 100mm, a width of 75mm, and a thickness of 0.15mm, 1.2mm, and 1.5mm respectively, and perform mechanical grinding to remove Oxide film and grease on the surface, and make the surface of the plate have a certain roughness. The alloy plates are stacked together in the order of titanium, aluminum, and magnesium to form a three-layer metal laminate. Holes are punched on both sides of one end of the plate, riveted together with pure aluminum rivets, and the end is ground into a wedge shape. Put the above-mentioned titanium / aluminum / magnesium laminate into a resistance furnace and heat it to 400°C. After holding the heat for 8 minutes, it is immediately sent to a rolling mill for hot rolling and compounding. The rolling speed is 0.5m / s and the deformation is 40%. Aluminum / magnesium three-layer composite sheet. Such as figure 1...

Embodiment 2

[0017] Take one piece of hot-rolled plate of TC4 titanium alloy, 6061 aluminum alloy and AZ31B magnesium alloy with a length of 100mm, a width of 75mm, and a thickness of 0.5mm, 2mm, and 1mm respectively, and perform mechanical grinding to remove the surface oxide film and grease. The sequence of aluminum / magnesium is stacked together to form a three-layer metal laminate. Holes are punched on both sides of one end of the board, riveted together with pure aluminum rivets, and the end is polished into a wedge shape. Put the above-mentioned titanium / aluminum / magnesium laminate into a resistance furnace at 450°C for 8 minutes, and then immediately send it to a rolling mill for hot rolling and compounding. The rolling speed is 0.5m / s, and the deformation is 50%. The titanium / aluminum / magnesium Three-layer composite board. The tensile strength, yield strength and elongation of the titanium / aluminum / magnesium composite plate are 425MPa, 365MPa and 9.5% respectively; the interface bon...

Embodiment 3

[0019] Take TC4 titanium alloy, 6061 aluminum alloy and AZ31B magnesium alloy hot-rolled plates with a length of 100mm, a width of 75mm, and a thickness of 0.2mm, 2.5mm, and 2mm respectively, and perform mechanical grinding to remove the surface oxide film and grease, and press titanium / aluminum / Magnesium are stacked together to form a three-layer metal laminate. Holes are punched on both sides of one end of the board, riveted together with pure aluminum rivets, and the end is polished into a wedge shape. Put the above-mentioned titanium / aluminum / magnesium laminate into a 350°C resistance furnace for 8 minutes, and then immediately send it to a rolling mill for hot rolling and compounding. The rolling speed is 0.8m / s and the deformation is 30%. The titanium / aluminum / magnesium Three-layer composite board. The tensile strength, yield strength and elongation of the titanium / aluminum / magnesium composite plate are 293MPa, 236MPa and 11.2% respectively; the interface bonding stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com