Method for determining deformation heat treatment conditions for improving 2219 aluminium alloy performance

A technology of aluminum alloy and high performance, which is applied in the field of deformation heat treatment conditions, can solve the problems of low tensile properties and hardness values of 2219 aluminum alloy, and limited application range, etc., and achieve the effect of solving insufficient database, improving strength and hardness, and expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

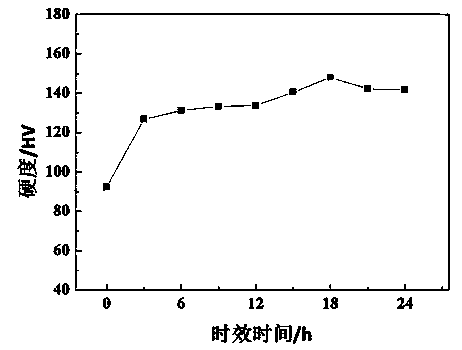

[0020] The 2219 aluminum alloy sheet used in the experiment was provided by Tianjin Aerospace Long March Rocket Manufacturing Co., Ltd. The sheet is in an annealed state, and the thickness of the sheet is 7 mm. The hardness sample is a 10mm×10mm block with a thickness of 7mm. Tensile samples are processed and formulated according to GB / G 228-2002 "Metallic Materials Tensile Test Methods". Nine groups of samples were prepared, wherein each group of samples consisted of two hardness samples and two tensile samples, all the hardness samples were of the same size, and all the tensile test samples were of the same size. Each sample was solution treated at 535°C for 40 minutes, and then the sample was quenched in water at room temperature for 5 minutes. Aging treatment for 0h, 3h, 6h, 9h, 12h, 15h, 18h, 21h and 24h, and then air-cool the sample to room temperature. The hardness sample after air cooling was tested with Everone MH-6 durometer, and the tensile sample after air coolin...

Embodiment 2

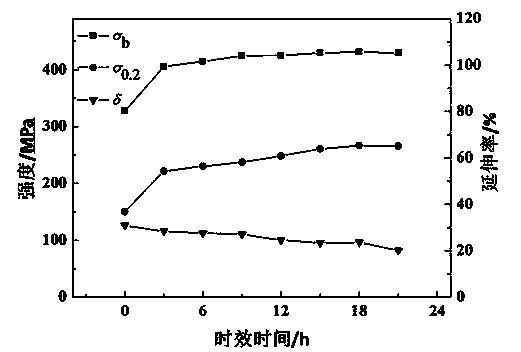

[0022] Take ten groups of samples and take two hardness samples and two tensile samples for each group of samples, and the size of the samples is the same as that of the first embodiment. Ten groups of samples were solution treated at 535°C for 40 minutes, then quenched in water at room temperature for 5 minutes, and the quenching transfer time was less than 10 seconds, and finally ten groups of hardness and tensile samples were aged in an oven at 175°C for 0h , 1h, 2h, 3h, 6h, 9h, 12h, 15h, 18h, 21h, and then air-cool the sample to room temperature. The sample is tested for hardness and tensile properties, and the model of the testing instrument used is the same as that of Example 1. The curves of hardness, tensile strength, elongation and aging treatment time of 2219 aluminum alloy at the aging temperature of 175 ℃ were drawn respectively, as shown in image 3 , Figure 4 shown.

Embodiment 3

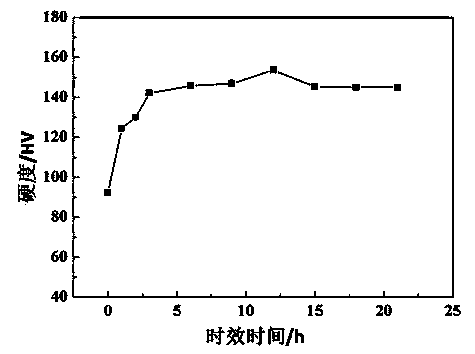

[0024]Take eight groups of samples and take two hardness samples and two tensile samples for each group of samples, and the size of the samples is the same as that of Example 1. The eight groups of samples were solution treated at 535°C for 40 minutes, then quenched in water at room temperature for 5 minutes, and the quenching transfer time was less than 10 seconds, and finally the eight groups of hardness and tensile samples were aged in an oven at 190°C for 0h , 20min, 40min, 2h, 4h, 6h, 8h, 10h, and then air-cool the sample to room temperature. The sample is tested for hardness and tensile properties, and the model of the testing instrument used is the same as that of Example 1. The curves of hardness, tensile strength, elongation and aging treatment time of 2219 aluminum alloy at the aging temperature of 190 ℃ were drawn respectively, as shown in Figure 5 , Figure 6 shown. Through the analysis of the strength, hardness and elongation of Examples 1~3, it is obtained th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com