Aging heat treatment method of 2219 aluminum alloy

A heat treatment method and aging treatment technology, applied in the field of aluminum alloy heat treatment, can solve the problems of poor welding performance, low corrosion resistance, low tensile properties and hardness values of 2219 aluminum alloy, so as to improve the strength and hardness and expand the application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

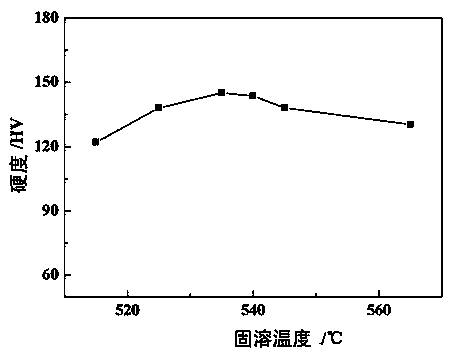

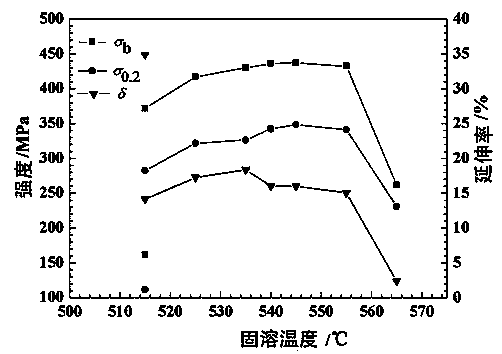

[0020] The 2219 aluminum alloy sheet used in the experiment was provided by Tianjin Aerospace Long March Rocket Manufacturing Co., Ltd. The sheet is in an annealed state, and the thickness of the sheet is 7 mm. The hardness sample is a 10mm×10mm block with a thickness of 7mm. Tensile samples are processed and formulated according to GB / G 228-2002 "Metallic Materials Tensile Test Methods". Take six groups of samples and take two hardness samples and two tensile samples for each group of samples, and the dimensions are the same. Solution treatment was carried out at 515°C, 525°C, 535°C, 540°C, 545°C and 565°C for 30 minutes, and then the treated samples at each solution temperature were placed in water at room temperature. Quenching for 5 minutes, wherein the quenching transfer time is less than 10 seconds, and finally the sample is aged in an oven at 175 ° C for 15 h, and then the sample is air-cooled. Metallographic analysis of the sample: the model of optical microscope use...

Embodiment 2

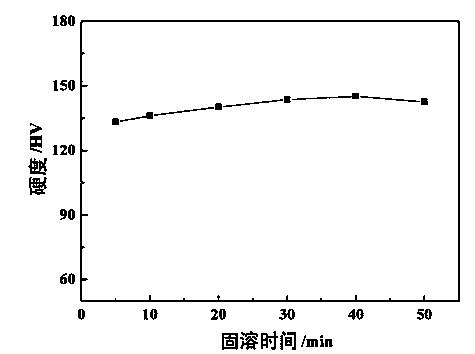

[0022] Take six groups of samples and take two hardness samples and two tensile samples for each group of samples, and the size of the samples is the same as that of Example 1. The five groups of samples were solution treated at 535°C for 5, 10, 20, 30, and 40 minutes respectively, and then quenched in water at room temperature for 5 minutes, wherein the quenching transfer time was less than 10 seconds, and finally the samples were treated at 175 °C in an oven for 15 h, and then the samples were air-cooled. The sample is subjected to metallographic structure analysis, hardness and tensile property test, and the model of the testing instrument used is the same as that of Example 1. Hardness and tensile strength as image 3 , Figure 4 shown.

Embodiment 3

[0024] Take nine groups of samples and take two hardness samples and two tensile samples for each group of samples, and the size of the samples is the same as that of the first embodiment. Nine groups of samples were solid solution treated at 535°C for 40min, then quenched in water at room temperature for 5min, wherein the quenching transfer time was less than 10 seconds, and finally nine groups of hardness and tensile samples were respectively placed in an oven at 160°C Aging 0h, 3h, 6h, 9h, 12h, 15h, 18h, 21h, 24h, and then air-cool the sample. The sample is subjected to metallographic structure analysis, hardness and tensile property test, and the model of the testing instrument used is the same as that of Example 1. Hardness and tensile strength as Figure 5 , Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com