Method for welding non-defective low-energy-consumption 2219 aluminum alloy

A welding method and aluminum alloy technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of unresolved AC arc welding instability, unstable welding process, small welding penetration, etc., to reduce porosity and other defects, welding current reduction, and the effect of increasing welding penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

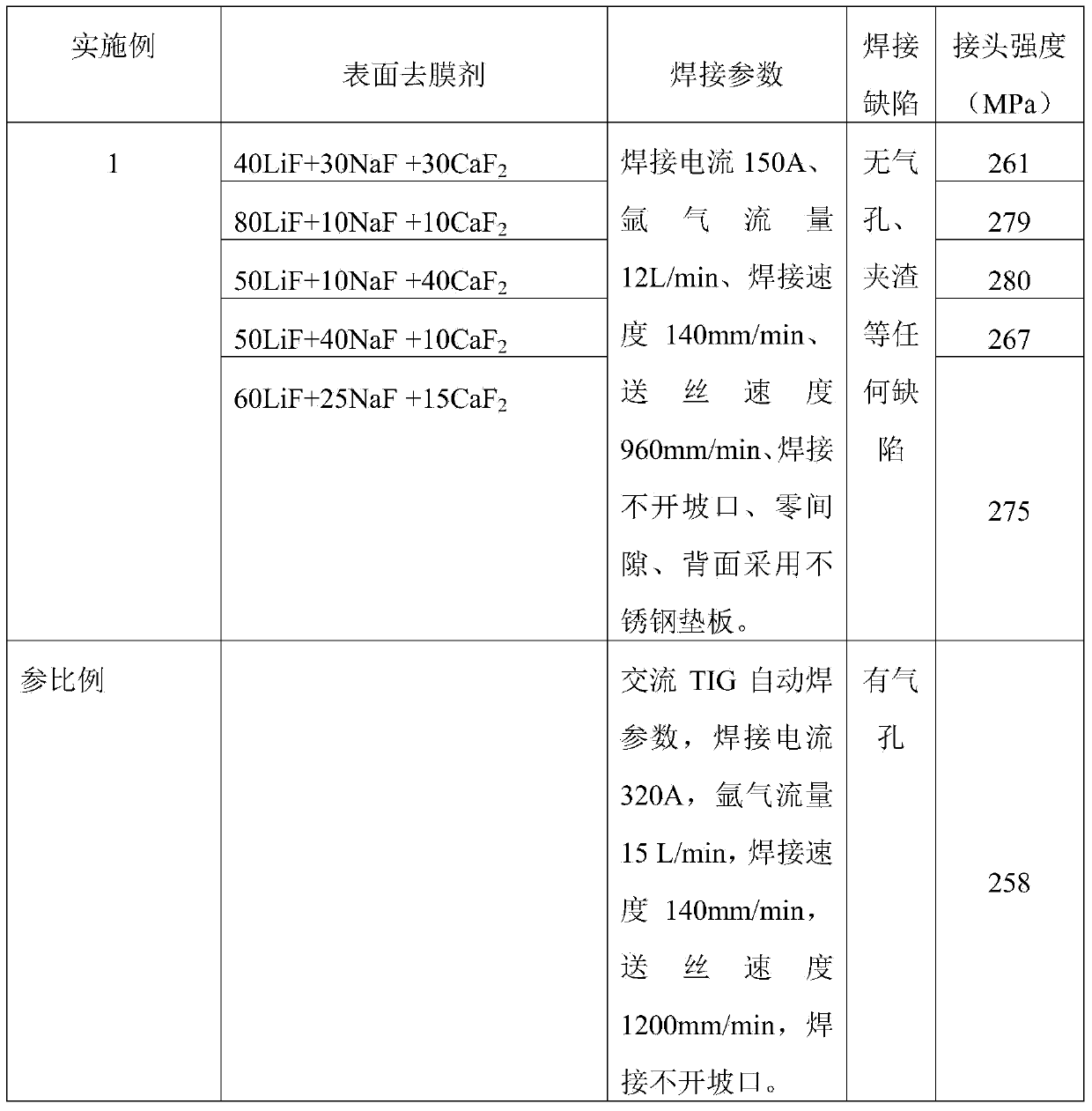

[0025] Example 1: DC welding of 2219 aluminum alloy with a thickness of 4mm

[0026] Weigh LiF, NaF, CaF according to the ratio 2 , the particle size of each fluoride is less than 10 μm, mix evenly, and make a paste with absolute ethanol. Clean the surface of 2219 aluminum alloy before welding, and then use a brush to evenly coat the chemically cleaned 2219 aluminum alloy on the surface to be welded. The 4mm thick 2219 aluminum alloy plate is butt welded by TIG DC positive polarity welding, and the defect detection and mechanical performance test are carried out after welding.

[0027] See the following table for specific proportioning ingredients, welding parameters and average tensile strength of welded joints:

[0028]

[0029] Test conditions: MTS-880 universal material testing machine is used to test the tensile strength of the above-mentioned 2219 aluminum alloy welded joints.

Embodiment 2

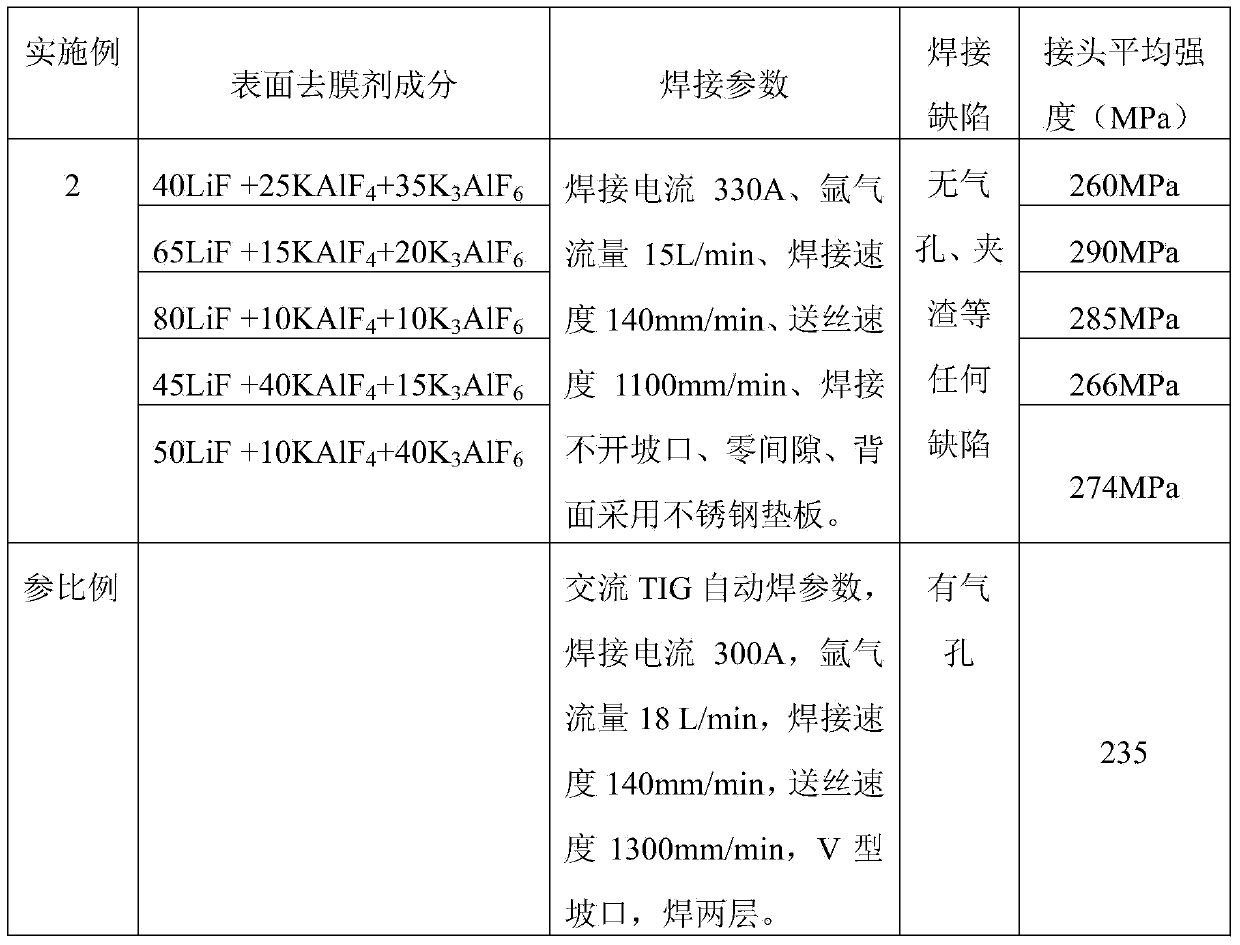

[0030] Embodiment 2: DC welding of 2219 aluminum alloy with a thickness of 8 mm

[0031] Weigh LiF and KAlF according to the ratio 4 、K 3 AlF 6 , the particle size of each fluoride is less than 10 μm, mix evenly, and make a paste with absolute ethanol. Clean the surface of 2219 aluminum alloy before welding, and then use a brush to evenly coat the chemically cleaned 2219 aluminum alloy on the surface to be welded. The 8mm thick 2219 aluminum alloy plate is butt welded by TIG DC positive polarity welding, and the defect detection and mechanical performance test are carried out after welding.

[0032] See the following table for specific proportioning ingredients, welding parameters and average tensile strength of welded joints:

[0033]

[0034] Test conditions: MTS-880 universal material testing machine is used to test the tensile strength of the above-mentioned 2219 aluminum alloy welded joints.

Embodiment 3

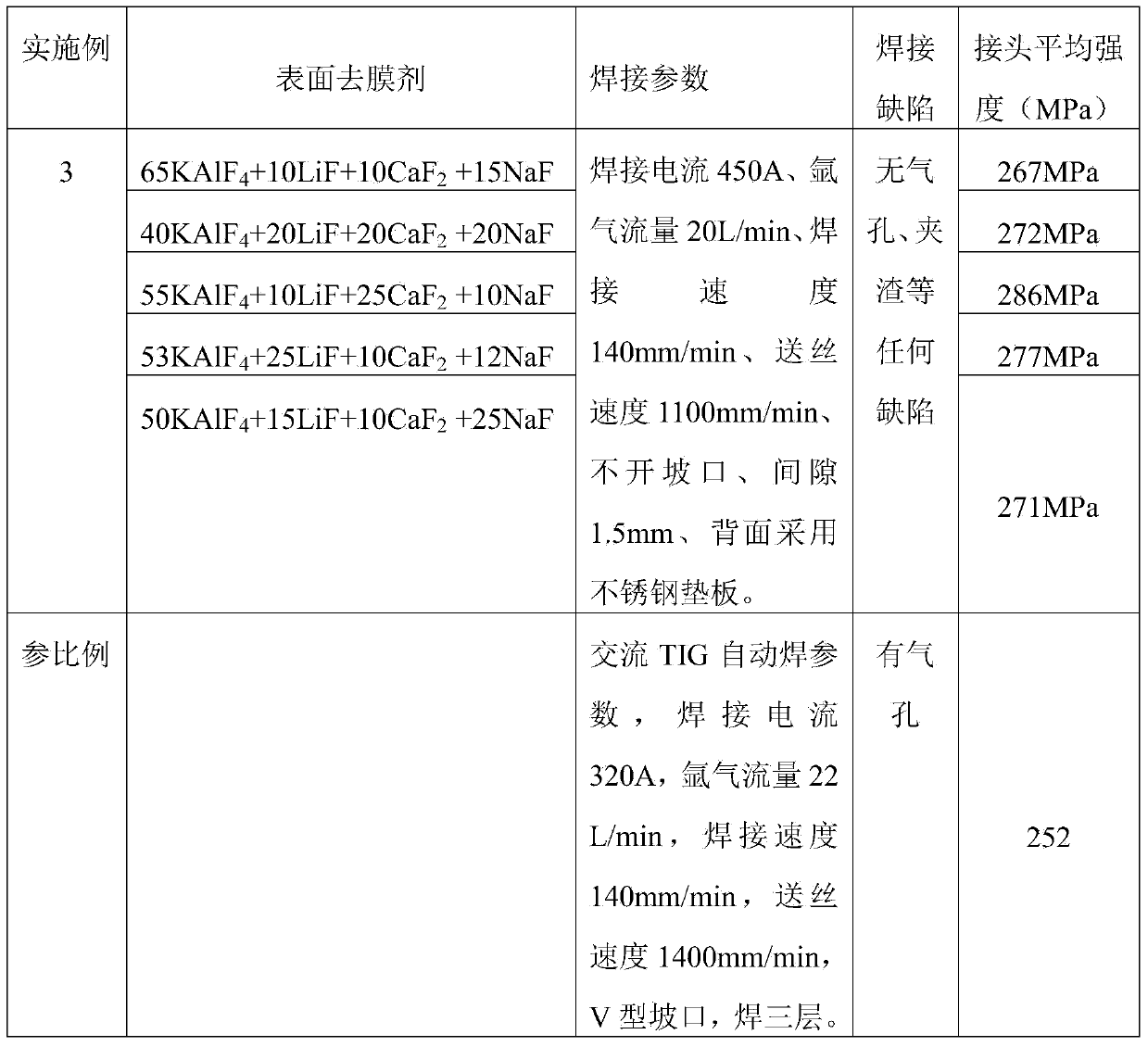

[0035] Embodiment 3: DC welding of 2219 aluminum alloy with a thickness of 12mm

[0036] Weigh KAlF according to the ratio 4 , LiF, CaF2 , NaF, the particle size of each fluoride is less than 10μm, mix evenly, and reconcile it into a paste with absolute ethanol. Clean the surface of 2219 aluminum alloy before welding, and then use a brush to evenly coat the chemically cleaned 2219 aluminum alloy on the surface to be welded. The 12mm thick 2219 aluminum alloy plate is butt welded by TIG DC positive polarity welding, and the defect detection and mechanical performance test are carried out after welding.

[0037] See the following table for specific proportioning ingredients, welding parameters and average tensile strength of welded joints:

[0038]

[0039] Test conditions: MTS-880 universal material testing machine is used to test the tensile strength of the above-mentioned 2219 aluminum alloy welded joints.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com